Abstract

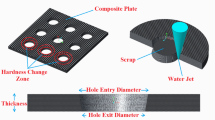

This paper presents a new method of piercing the carbon fibre reinforced polymer (CFRP) with abrasive water jet (AWJ), which can avoid delamination. The method consists of adding the abrasive particles in the water jet at the very beginning of jet formation, thus obtaining a mixed abrasive water jet during the first impact with the composite work piece. A new cutting system was designed and set up based on the proposed piercing method and was compared with a conventional AWJ cutting system. The main added values brought by this paper are: it validates our original concept; provides synthetic analyses, the effects of the AWJ homogeneity, and the abrasive inlet angle on the CFRP delamination, and it brings a complete set of recommendations on how to overcome the industrial difficulties caused by the delamination of the composite materials, during the piercing with AWJ.

Similar content being viewed by others

Abbreviations

- Dext :

-

Delamination extent [mm]

- Dmax :

-

The maximum diameter of delamination [mm]

- Dnom :

-

The nominal hole diameter [mm]

- do :

-

Water orifice diameter [mm]

- df :

-

Focusing tube diameter [mm]

- lf :

-

Focusing tube length [mm]

- ma :

-

Abrasives mass flow [kg/min]

- P:

-

Water pressure [MPa]

- Ra :

-

Surface roughness [µm]

- rk :

-

The top edge radius [mm]

- t:

-

Material thickness [mm]

- SOD:

-

Stand-off distance [mm]

- Ψ:

-

Abrasive inlet angle [degree]

- AE:

-

Acoustic emission

- AWJ:

-

Abrasive water jet

- CCD:

-

Central composite design

- CFRP:

-

Carbon fibre reinforced polymer/plastic

- DoE:

-

Design of experiments

- IDZ:

-

Initial damage zone

- UHP:

-

Ultra high-pressure pump

- RSM:

-

Response Surface Methodology

- RCZ:

-

Rough cutting zone

- SCZ:

-

Smooth cutting zone

- WJ:

-

Water jet

References

Aamir M, Tolouei-Rad M, Giasin K, Nosrati A (2019) Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: a review. Int J Adv Manuf Technol 105:2289–2308. https://doi.org/10.1007/s00170-019-04348-z

Kim G, Denos BR, Sterkenburg R (2020) Influence of different piercing methods of abrasive waterjet on delamination of fiber reinforced composite laminate. Compos Struct 240:112065. https://doi.org/10.1016/j.compstruct.2020.112065

Jia Z, Chen C, Wang F, Zhang C, Wang Q (2020) Analytical model for delamination of CFRP during drilling of CFRP/metal stacks. Int J Adv Manuf Technol 106:5099–5109. https://doi.org/10.1007/s00170-020-05029-y

Xu J, Zhou L, Chen M, Ren F (2019) Experimental study on mechanical drilling of carbon/epoxy composite-Ti6Al4V stacks. Mater Manuf Processes 34:715–725. https://doi.org/10.1080/10426914.2019.1594275

Hashish M (2013) Trimming of CFRP aircraft components. WJTA-IMCA Conference and Expo September 9–11

Thongkaew K, Wang J, Li W (2019) An investigation of the hole machining processes on woven carbon-fiber reinforced polymers (CFRPs) using abrasive waterjets. Mach Sci Technol 23:19–38. https://doi.org/10.1080/10910344.2018.1449217

Liu X, Liang Z, Wen G, Yuan X (2019) Waterjet machining and research developments: a review. Int J Adv Manuf Technol 102:1257–1335. https://doi.org/10.1007/s00170-018-3094-3

Srinivasu DS, Axinte DA (2014) Mask-less pocket milling of composites by abrasive waterjets: an experimental investigation. J Manuf Sci Eng 136. https://doi.org/10.1115/1.4027181

Li W, Zhu H, Wang J, Huang C (2016) Radial-mode abrasive waterjet turning of short carbon–fiber-reinforced plastics. Mach Sci Technol 20:231–248. https://doi.org/10.1080/10910344.2016.1165836

Natarajan Y, Murugesan PK, Mohan M, Liyakath Ali Khan SA (2020) Abrasive water jet machining process: a state of art of review. J Manuf Process 49:271–322. https://doi.org/10.1016/j.jmapro.2019.11.030

Alsoufi MS (2017) State-of-the-art in abrasive water jet cutting technology and the promise for micro- and nano-machining. Int J Mech Eng Appl 5:1. https://doi.org/10.11648/j.ijmea.20170501.11

Thakur RK, Singh KK, Ramkumar J (2021) Impact of nanoclay filler reinforcement on CFRP composite performance during abrasive water jet machining. Mater Manuf Processes 36:1264–1273. https://doi.org/10.1080/10426914.2021.1906896

Bañon F, Sambruno A, Batista M, Simonet B, Salguero J (2020) Study of the surface quality of carbon fiber–reinforced thermoplastic matrix composite (CFRTP) machined by abrasive water jet (AWJM). Int J Adv Manuf Technol 107:3299–3313. https://doi.org/10.1007/s00170-020-05215-y

Phapale K, Singh R, Patil S, Singh RKP (2016) Delamination characterization and comparative assessment of delamination control techniques in abrasive water jet drilling of CFRP. Procedia Manufacturing 5:521–535. https://doi.org/10.1016/j.promfg.2016.08.043

Shanmugam DK, Nguyen T, Wang J (2008) A study of delamination on graphite/epoxy composites in abrasive waterjet machining. Compos A Appl Sci Manuf 39:923–929. https://doi.org/10.1016/j.compositesa.2008.04.001

Dhanawade A, Kumar S (2017) Experimental study of delamination and kerf geometry of carbon epoxy composite machined by abrasive water jet. J Compos Mater 51:3373–3390. https://doi.org/10.1177/0021998316688950

Ibraheem HMA, Iqbal A, Hashemipour M (2015) Numerical optimization of hole making in GFRP composite using abrasive water jet machining process. J Chin Inst Eng 38:66–76. https://doi.org/10.1080/02533839.2014.953240

Alberdi A, Artaza T, Suárez A, Rivero A, Girot F (2016) An experimental study on abrasive waterjet cutting of CFRP/Ti6Al4V stacks for drilling operations. Int J Adv Manuf Technol 86:691–704. https://doi.org/10.1007/s00170-015-8192-x

Dhakal HN, Ismail SO, Ojo SO, Paggi M, Smith JR (2018) Abrasive water jet drilling of advanced sustainable bio-fibre-reinforced polymer/hybrid composites: a comprehensive analysis of machining-induced damage responses. Int J Adv Manuf Technol 99:2833–2847. https://doi.org/10.1007/s00170-018-2670-x

Chen L, Lemma E, Siores E, Wang J (2002) Study of cutting fiber-reinforced composites by using abrasive water-jet with cutting head oscillation. Compos Struct 57. https://doi.org/10.1016/S0263-8223(02)00097-1

Kechagias J, Petropoulos G, Vaxevanidis N (2012) Application of Taguchi design for quality characterization of abrasive water jet machining of TRIP sheet steels. Int J Adv Manuf Technol 62:635–643. https://doi.org/10.1007/s00170-011-3815-3

Li M, Huang M, Yang X, Li S, Wei K (2018) Experimental study on hole quality and its impact on tensile behavior following pure and abrasive waterjet cutting of plain woven CFRP laminates. Int J Adv Manuf Technol 99:2481–2490. https://doi.org/10.1007/s00170-018-2589-2

Liu D, Tang Y, Cong WL (2012) A review of mechanical drilling for composite laminates. Compos Struct 94:1265–1279. https://doi.org/10.1016/j.compstruct.2011.11.024

Vigneshwaran S, Uthayakumar M, Arumugaprabu V (2018) Abrasive water jet machining of fiber-reinforced composite materials. J Reinf Plast Compos 37:230–237. https://doi.org/10.1177/0731684417740771

WARDJet Corporation (2019) Waterjet Piercing Techniques and When to Use Them. In: WARDJet. https://wardjet.com/news/waterjet-piercing-techniques. Accessed 22 Apr 2021

OMAX Corporation (2016) 4 Piercing Methods In Abrasive Waterjet Machining. In: OMAX. https://www.omax.com/news/blog/4-piercing-methods-abrasive-waterjet-machining. Accessed 22 Apr 2021

Fredin J, Jönsson A (2011) Experimentation on piercing with abrasive waterjet. International Journal of Industrial and Manufacturing Engineering 59:2393–2399

Olsen JH (2007) Recent developments in abrasive jet software. https://www.thefabricator.com/thefabricator/article/waterjetcutting/recent-developments-in-abrasive-jet-software. Accessed 22 Apr 2021

Rabani A, Marinescu I, Axinte D (2012) Acoustic emission energy transfer rate: a method for monitoring abrasive waterjet milling. Int J Mach Tools Manuf 61:80–89. https://doi.org/10.1016/j.ijmachtools.2012.05.012

Axinte DA, Kong MC (2009) An integrated monitoring method to supervise waterjet machining. CIRP Ann 58:303–306. https://doi.org/10.1016/j.cirp.2009.03.022

Pahuja R, Ramulu M (2019) Surface quality monitoring in abrasive water jet machining of Ti6Al4V–CFRP stacks through wavelet packet analysis of acoustic emission signals. Int J Adv Manuf Technol 104:4091–4104. https://doi.org/10.1007/s00170-019-04177-0

Funding

This research was supported by HORIZON 2020 – DiCoMI Project, “Directional Composites through Manufacturing Innovation”, GA Nr. 778068.

Author information

Authors and Affiliations

Contributions

All authors contributed to design the proposed method. I.A.P and A.I.P. carried out the experiments. A.I.P. performed the measurements and optical analysis. All authors analysed the experimental results and wrote of the manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The authors agreed with the submission of the manuscript to the journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Popan, I.A., Balc, N. & Popan, A.I. Avoiding carbon fibre reinforced polymer delamination during abrasive water jet piercing: a new piercing method. Int J Adv Manuf Technol 119, 1139–1152 (2022). https://doi.org/10.1007/s00170-021-08294-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-08294-7