Abstract

In the present paper, the influence of sheet thickness, nozzle diameter, standoff distance, and traverse speed during abrasive water jet machining (AWJM) of transformation-induced plasticity (TRIP) sheet steels on surface quality characteristics (kerf geometry and surface roughness) was investigated. The experiments were designed using Taguchi methodology and carried out by AWJ Machining TRIP 700 CR-FH and TRIP 800 HR-FH steel sheets. As response variables, mean kerf width and average surface roughness were selected. The experimental results were analyzed using analysis of means and analysis of variance methods in order to correlate the AWJM process parameters the response variables. In addition, regression models were obtained using the experimental results and validated with six independent experiments. The reported results indicate that the proposed methodology can satisfactorily analyze the surface roughness and the mean kerf in AWJM; moreover, it can be considered as valuable tools for process planning in workshop.

Similar content being viewed by others

References

Jain VK (2008) Advanced (non-traditional) machining processes. In: Davim JP (ed) Machining—fundamentals and recent advances. Springer, New York, p 299

Wang J, Wong WCK (1999) Study of abrasive waterjet cutting of metallic coated sheet steels. Int J Mach Tools Manuf 39:855

Momber AW, Kovacevic R (1997) Principles of abrasive water jet machining. Springer, New York

Vaxevanidis NM, Markopoulos A, Petropoulos G (2010) Artificial neural network modelling of surface quality characteristics in abrasive water jet machining of trip steel sheet. In: Davim JP (ed) Artificial intelligence in manufacturing research. Nova, New York, p p79

Hashish M (1989) Pressure effect in abrasive waterjet (AWJ) machining. J Eng Mater-T ASME 111(7):221

Vassilakis S, Petropoulos G, Sokovic M, Vaxevanidis NM, Ntziantzias I (2007) Macrogeometric and surface roughness quality microgeomety of TRIP steel sheet processed by abrasive waterjet machining. Proceedings of the 9th Int. Conf. on Management of Innovative Technologies (MIT’ 07), Piran, Slovenia, p196

Akkurt A, Kulekci MK, Seker U, Ercan F (2004) Effect of feed rate on surface roughness in abrasive waterjet cutting applications. J Mater Process Technol 147(3):389

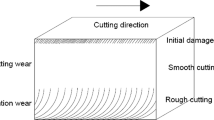

Arola D, Ramulu M (1997) Material removal in abrasive waterjet machining of metals surface integrity and texture. Wear 210:50

Wang J (1999) Abrasive waterjet machining of polymer matrix composites: cutting performance erosive analysis and predictive models. Int J Adv Manuf Technol 15:757

Seo YW, Ramulu M, Kim D (2003) Machinability of titanium alloy (Ti–6Al–4 V) by abrasive waterjets. Proc Inst Mech Eng B 217(12):1709

Gudimetla P, Wang J, Wong W (2002) Kerf formation analysis in the abrasive waterjet cutting of industrial ceramics. J Mater Process Technol 128:123

Hascalik A, Ulas C, Gurun H (2007) Effect of traverse speed on abrasive waterjet machining of Ti–6Al–4 V alloy. Mater Des 28(6):1953

Jegaraj JJR, Babu NR (2007) A soft computing approach for controlling the quality of cut with abrasive waterjet cutting system experiencing orifice and focusing tube wear. J Mater Process Technol 185:217

Valicek J et al (2007) Experimental analysis of irregularities of metallic surfaces generated by abrasive waterjet. Int J Mach Tool Manuf 47(11):1786

Kök M, Kanca E, Eyercioğlu O (2011) Prediction of surface roughness in waterjet machining of particle reinforced MMCs using genetic expression programming. Int J Adv Manuf Technol 55:955

Rozario Jegaraj JJ, Ramesh Babu N (2007) A soft computing approach for controlling the quality of cut with abrasive waterjet cutting system experiencing orifice and focusing tube wear. J Mater Process Technol 185:217

Kovacevic R, Hashish M, Mohan R, Ramulu M, Kim TJ, Geskin ES (1997) State of the art of research and development in abrasive waterjet machining. J Manuf Sci Eng-T ASME 119:776

Phadke MS (1989) Quality engineering using robust design. Prentice-Hall, Englewood Cliffs, p 286

Chryssolouris G, Kechagias J, Moustakas P, Koutras E (2003) An experimental investigation of the tensile strength of parts produced by laminated object manufacturing (LOM) process. CIRP J Manuf Syst 32(5)

Kwak JS (2005) Application of Taguchi and response surface methodologies for geometric error in surface grinding process. Int J Mach Tool Manuf 45:327

Kechagias J (2007) An experimental investigation of the surface roughness of parts produced by LOM process. Rapid Prototyping J 13(1):17

Kechagias J (2007) Investigation of LOM process quality using design of experiments approach. Rapid Prototyping J 13(5):316

Kechagias J, Iakovakis V (2009) A neural network solution for LOM process performance. Int J Adv Manuf Technol 43(11):1214

Petropoulos G, Tsolakis N, Vaxevanidis NM, Antoniadis A (2009) Topographic description of abrasive waterjet machined surfaces, Proceedings 2nd European Conference on Tribology (ECOTRIB 2009), Pisa, Italy, p309

Kechagias J, Petropoulos G, Iakovakis V, Maropoulos S (2009) An investigation of surface texture parameters during turning of a reinforced polymer composite using design of experiments and analysis. Int J Exp Des Process Optim 1(2/3):164

Author information

Authors and Affiliations

Corresponding author

Additional information

Prof. G. Petropoulos passed away suddenly on 20 July 2010 during the review process of this manuscript. He is greatly missed by his colleagues and friends.

Rights and permissions

About this article

Cite this article

Kechagias, J., Petropoulos, G. & Vaxevanidis, N. Application of Taguchi design for quality characterization of abrasive water jet machining of TRIP sheet steels. Int J Adv Manuf Technol 62, 635–643 (2012). https://doi.org/10.1007/s00170-011-3815-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3815-3