Abstract

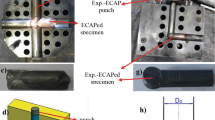

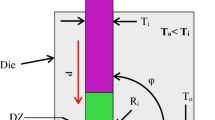

In this study, a novel severe plastic deformation method, named as thin-walled open channel angular pressing (TWO-CAP), was developed and applied to AZ31 magnesium alloy beams in U-type cross-sectional shape. First of all, the principles of the method with all parameters were determined, and the analytical model of the system was generated, and then the study was supported with the numerical analysis. Then, a proper experimental setup was established by considering theoretic outputs. After that, AZ31 magnesium alloy specimens were machined from bulk material in U-type shape as to fit the die channel, and then these specimens were annealed and pressed along the TWO-CAP die. Following the experimental studies, the specimens were tested in order to define the changes in mechanical and microstructural properties. In this stage, the tension test and hardness test were applied to determine the mechanical properties, while optical microscope, scanning electron microscope, energy dispersive spectrometry, X-ray diffraction, and transmission electron microscope analyses were applied to see the changes in microstructure. As a result, an improvement on strength, hardness, and toughness was observed depending on the changes on the microstructure and grain refinement due to the large plastic deformation.

Similar content being viewed by others

References

Valiev RZ (2014) Superior strength in ultrafine-grained materials produced by SPD processing. Mater Trans 55:13–18. https://doi.org/10.2320/matertrans.MA201325

Kaya H, Uçar M, Cengiz A, Samur R, Özyürek D, Çalişkan A (2014) Novel molding technique for ECAP process and effects on hardness of AA7075. Mechanika 20:5–10. https://doi.org/10.5755/j01.mech.20.1.4207

Özbeyaz K, Kaya H, Kentli A, Şahbaz M, Öğüt S (2019) Mechanical properties and electrical conductivity performance of ECAP processed AA2024 alloy. Indian J Chem Technol 26:266–269

Kawasaki M, Figueiredo RB, Langdon TG (2012) Twenty-five years of severe plastic deformation: recent developments in evaluating the degree of homogeneity through the thickness of disks processed by high-pressure torsion. J Mater Sci 47:7719–7725. https://doi.org/10.1007/s10853-012-6507-y

Huang J, Zhu YT, Alexander DJ, Liao X, Lowe TC, Asaro RJ (2004) Development of repetitive corrugation and straightening. Mater Sci Eng A 371:35–39. https://doi.org/10.1016/S0921-5093(03)00114-X

Khatami R, Fattah-alhosseini A, Mazaheri Y, Keshavarz MK, Haghshenas M (2017) Microstructural evolution and mechanical properties of ultrafine grained AA2024 processed by accumulative roll bonding. Int J Adv Manuf Technol 93:681–689. https://doi.org/10.1007/s00170-017-0547-z

Richert M, Stüwe HP, Zehetbauer MJ, Richert J, Pippan R, Motz C, Schafler E (2003) Work hardening and microstructure of AlMg5 after severe plastic deformation by cyclic extrusion and compression. Mater Sci Eng A 355:180–185. https://doi.org/10.1016/S0921-5093(03)00046-7

Bahmani A, Arthanari S, Shin KS (2019) Improved corrosion resistant and strength of a magnesium alloy using multi-directional forging (MDF). Int J Adv Manuf Technol 1–13 https://doi.org/10.1007/s00170-019-04176-1

Faraji G, Babaei A, Mosavi Mashadi M, Abrinia K (2012) Parallel tubular channel angular pressing (PTCAP) as a new severe plastic deformation method for cylindrical tubes. Mater Lett 77:82–85. https://doi.org/10.1016/j.matlet.2012.03.007

Zangiabadi A, Kazeminezhad M (2011) Development of a novel severe plastic deformation method for tubular materials: tube channel pressing (TCP). Mater Sci Eng A 528:5066–5072. https://doi.org/10.1016/j.msea.2011.03.012

Beygelzimer Y, Orlov D, Varyukhin V (2002) A new severe plastic deformation method: twist extrusion. In: Ultrafine grained materials II. John Wiley & Sons, Inc., Hoboken, pp 297–304

Bagherpour E, Pardis N, Reihanian M, Ebrahimi R (2019) An overview on severe plastic deformation: research status, techniques classification, microstructure evolution, and applications. Int J Adv Manuf Technol 100:1647–1694. https://doi.org/10.1007/s00170-018-2652-z

Jiang J, Yuan T, Zhang W, Ma A, Song D, Wu Y (2018) Effect of equal-channel angular pressing and post-aging on impact toughness of Al-Li alloys. Mater Sci Eng A 733:385–392. https://doi.org/10.1016/J.MSEA.2018.07.037

Kulekci MK (2008) Magnesium and its alloys applications in automotive industry. Int J Adv Manuf Technol 39:851–865. https://doi.org/10.1007/s00170-007-1279-2

Şahbaz M (2019) Development of a novel severe plastic deformation method for a thin-walled open section beam: thin-walled open channel angular pressing (TWO-CAP). Dissertation, Marmara University

Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon TG (1996) Principle of equal-channel angular pressing for the processing of ultra-fine grained materials. Scr Mater 35:143–146. https://doi.org/10.1016/1359-6462(96)00107-8

Lin HK, Huang JC, Langdon TG (2005) Relationship between texture and low temperature super plasticity in an extruded AZ31 Mg alloy processed by ECAP. Mater Sci Eng A 402:250–257. https://doi.org/10.1016/J.MSEA.2005.04.018

Dziubińska A, Gontarz A, Horzelska K, Pieśko P (2015) The microstructure and mechanical properties of AZ31 magnesium alloy aircraft brackets produced by a new forging technology. Proc Manuf 2:337–341. https://doi.org/10.1016/J.PROMFG.2015.07.059

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zechetbauer MJ, Zhu YT (2006) Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 58:33–39. https://doi.org/10.1007/s11837-006-0213-7

Ghorbani A, Zarei-Hanzaki A, Dastranjy Nezhadfar P, Maghsoudi MH (2019) Microstructural evolution and room temperature mechanical properties of AZ31 alloy processed through hot constrained compression. Int J Adv Manuf Technol 102:2307–2317. https://doi.org/10.1007/s00170-019-03321-0

Hu H, Qin X, Zhang D, Ma X (2018) A novel severe plastic deformation method for manufacturing AZ31 magnesium alloy tube. Int J Adv Manuf Technol 98:897–903. https://doi.org/10.1007/s00170-018-2179-3

Zhou H, Hu L, Sun Y, Zhang H, Duan C, Yu H (2016) Synthesis of nanocrystalline AZ31 magnesium alloy with titanium addition by mechanical milling. Mater Charact 113:108–116. https://doi.org/10.1016/j.matchar.2016.01.014

Zhang W, Lu J, Huo W, Zhang Y, Wei Q (2018) Microstructural evolution of AZ31 magnesium alloy subjected to sliding friction treatment. Philos Mag 98:1576–1593. https://doi.org/10.1080/14786435.2018.1447701

Fatemi SM, Zarei-Hanzaki A (2017) Mechanical behavior of an ultrafine/nano grained magnesium alloy. J Ultrafine Grained Nanostruct Mater 50:6–15. https://doi.org/10.7508/JUFGNSM.2017.01.02

Chapuis A, Wang Z, Liu Q (2016) Influence of material parameters on modeling plastic deformation of Mg alloys. Mater Sci Eng A 655:244–250. https://doi.org/10.1016/J.MSEA.2015.12.067

Vaughan MW, Nasim W, Dogan E, Herrington JS, Proust G, Benzerga AA, Karaman I (2019) Interplay between the effects of deformation mechanisms and dynamic recrystallization on the failure of Mg-3Al-1Zn. Acta Mater 168:448–472. https://doi.org/10.1016/J.ACTAMAT.2019.02.010

Guo W, Wang QD, Ye B, Liu MP, Peng T, Liu XT, Zhou H (2012) Enhanced microstructure homogeneity and mechanical properties of AZ31 magnesium alloy by repetitive upsetting. Mater Sci Eng A 540:115–122. https://doi.org/10.1016/J.MSEA.2012.01.111

Tao NR, Wang ZB, Tong WP, Sui ML, Lu J, Lu K (2002) An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater 50:4603–4616. https://doi.org/10.1016/S1359-6454(02)00310-5

Acknowledgments

We would like to thank Prof. Dr. Mehmet UÇAR for his support for the laboratory studies. This work was supported by the Marmara University Scientific Research Project within the project number FEN-C-DRP-120417-0183 and FEN-A-090217-0045.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Şahbaz, M., Kaya, H. & Kentli, A. A new severe plastic deformation method: thin-walled open channel angular pressing (TWO-CAP). Int J Adv Manuf Technol 106, 1487–1496 (2020). https://doi.org/10.1007/s00170-019-04748-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04748-1