Abstract

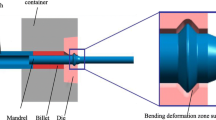

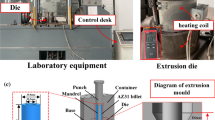

A new severe plastic deformation called TES (tube extrusion shearing) process, which combines direct extrusion with two-step shearing, is developed to manufacture tubes made of wrought AZ31 magnesium alloy. To explore the deformation mechanisms of TES process, both experiment and numerical simulation are carried out. Three-dimensional finite element modeling is used to investigate the plastic deformation behaviors of wrought magnesium alloy during TES process. Experiments show that by use of TES process the microstructures can be refined to 50% of the original grain size and with more uniform grain distribution. TES process could improve hardness obviously by comparing which fabricated by direct extrusion. Numerical results indicate TES increases the cumulative strains effectively by direct extrusion and additional shearing.

Similar content being viewed by others

Change history

14 April 2023

A Correction to this paper has been published: https://doi.org/10.1007/s00170-023-11431-z

References

Li S, Bourke MAM, Beyerlein IJ, Alexander DJ, Clausen B (2004) Finite element analysis of the plastic deformation zone and working load in equal channel angular extrusion. Mater Sci Eng A 382:217–236

Matsubara K, Miyahara Y, Horita Z, Langdon TG (2003) Developing superplasticity in a magnesium alloy through a combination of extrusion and ecap. Acta Mater 51:3073–3084

Zhang D, Hu H, Pan F, Yang M, Zhang J (2010) Numerical and physical simulation of new SPD method combining extrusion and equal channel angular pressing for AZ31 magnesium alloy. Trans Nonferrous Metals Soc China 20:478–483

Liu G, Zhou J, Duszczyk J (2007) Finite element simulation of magnesium extrusion to manufacture a cross-shaped profile. J Manuf Sci Eng 129:607–614

Chandrasekaran M, Yong M (2004) Effect of materials and temperature on the forward extrusion of magnesium alloys. Mater Sci Eng A 381:308–319

Orlov D, Raab G, Lamark TT, Popov M, Estrin Y (2011) Improvement of mechanical properties of magnesium alloy zk60 by integrated extrusion and equal channel angular pressing. Acta Mater 59:375–385

Basavaraj VP, Chakkingal U, Kumar TSP (2009) Study of channel angle influence on material flow and strain inhomogeneity in equal channel angular pressing using 3d finite element simulation. J Mater Process Technol 209:89–95

Figueiredo RB, Cetlin PR, Langdon TG (2007) The processing of difficult-to-work alloys by ecap with an emphasis on magnesium alloys. Acta Mater 55:4769–4779

Hu HJ, Huang WJ (2013) Effects of turning speed on high-speed turning by ultrafine-grained ceramic tool based on 3D finite element method and experiments. Int J Adv Manuf Technol 67:907–915

Faraji G, Yavari P, Aghdamifar S, Mashhadi MM (2014) Mechanical and microstructural properties of ultra-fine grained AZ91 magnesium alloy tubes processed via multi pass tubular channel angular pressing (TCAP). J Mater Sci Technol 30:134–138

Zhao ZD, Chen Q, Chao HY, Huang SH (2010) Microstructural evolution and tensile mechanical properties of thixoforged ZK60-Y magnesium alloys produced by two different routes. Mater Des 31:1906–1916

Chen Q, Zhao ZD, Chen G, Wang B (2015) Effect of accumulative plastic deformation on generation of spheroidal structure, thixoformability and mechanical properties of large-size AM60 magnesium alloy. J Alloys Compd 632:190–200

Chen Q, Yuan BG, Lin J, Xia XS, Zhao ZD, Shu DY (2014) Comparisons of microstructure, thixoformability and mechanical properties of high performance wrought magnesium alloys reheated from the as-cast and extruded states. J Alloys Compd 584:63–75

Chen Q, Zhao ZD, Zhao ZX, Hu CK, Shu DY (2011) Microstructure development and thixoextrusion of magnesium alloy prepared by repetitive upsetting-extrusion. J Alloys Compd 509:7303–7315

Chen Q, Chen G, Han LN, Hu N, Han F, Zhao ZD, Xia XS, Wan YY (2015) Microstructure evolution of sicp/ZM6 (Mg-Nd-Zn) magnesium matrix composite in the semi-solid state. J Alloys Compd 656:67–76

Hu H, Zhai Z, Li Y, Wang H, Dai J (2015) Researches on physical field evolution of micro-cutting of steel H13 by micron scale ceramic cutter based on finite element modeling. Int J Adv Manuf Technol 78(9–12):1407–1414

Hu H-J, Huang W-J (2013) Studies on wears of ultrafine-grained ceramic tool and common ceramic tool during hard turning using Archard wear model. Int J Adv Manuf Technol 69(1–4):31–39

Hu H-J, Wang H, Zhai Z-Y, Li Y-Y, Fan J-Z, Zhongwen OU (2014) The influences of shear deformation on the evolutions of the extrusion shear for magnesium alloy. Int J Adv Manuf Technol 174(1–4):423–432

Hu H-J, Wang H, Zhai Z-Y, Li Y-Y, Fan J-Z, Ou Z-W (2014) Effects of channel angles on extrusion-shear for AZ31 magnesium alloy: modeling and experiments. Int J Adv Manuf Technol 76(9–12):1621–1630

Mofid MA, Abdollah-zadeh A, Hakan Gür C (2014) Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen. Int J Adv Manuf Technol 71(5–8):1493–1499

Feng F, Huang S, Hu J, Meng Z, Lei Y (2013) Analysis of the bulging process of an AZ31B magnesium alloy sheet with a uniform pressure coil. Int J Adv Manuf Technol 69(5–8):1537–1545

Rajakumar S, Razalrose A, Balasubramanian V (2013) Friction stir welding of AZ61A magnesium alloy. Int J Adv Manuf Technol 68(1–4):277–292

Funding

This research has been funded by the National Science Foundation of China (51771038 and 51571040), the Chongqing Research Program of Basic Research and Frontier Technology (cstc2015jcyjBX0054), and China Postdoctoral Science Foundation funded project (2015T81087 and 2014M552575).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, H., Qin, X., Zhang, D. et al. A novel severe plastic deformation method for manufacturing AZ31 magnesium alloy tube. Int J Adv Manuf Technol 98, 897–903 (2018). https://doi.org/10.1007/s00170-018-2179-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2179-3