Abstract

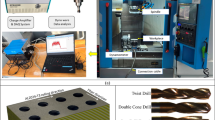

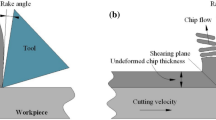

There are some problems in drilling Ti-6Al-4V/Al2024-T351 materials by traditional twist drill, such as big thrust force, big burr at outlet, and poor surface morphology. To solve these problems or reduce damage, low amplitude and high frequency vibrations are usually added in the direction of feed motion. This paper focuses on the study of geometric tool conventional drilling (CD) and ultrasonic-assisted drilling (UAD). Under ideal experimental conditions, through the combination of experiment and simulation, the drilling of laminated materials was investigated. The experimental results show that the UAD reduces the thrust force, burr height, torque, and temperature of laminated materials by 28.6%, 54.5%, 28.6%, and 13.2% respectively.

Similar content being viewed by others

References

Geng D, Liu Y, Shao Z, Lu Z, Cai J, Li X, Jiang X, Zhang D (2019) Delamination formation, evaluation and suppression during drilling of composite laminates: a review. Compos Struct 216:168–186

Subramanian K, Cook NH (1997) Sensing of drill wear and prediction of drill life. Trans ASME J Eng Indus 99:295–301

Liu D, Tang Y, Cong WL (2012) A review of mechanical drilling for composite laminates. Compos Struct 94:1265–1279

Uhlmann E, Mullany B, Biermann D, Rajurkar KP, Hausotte T, Brinksmeier E (2016) Process chains for high-precision components with micro-scale features. CIRP AnnManuf Technol 65:549–572

Caprino G, Tagilaferri V (1995) Damage developments in drilling glass fiber reinforced plastics. Int J Mach Tools Manuf 35:817–829

Mishra R, Malik J, Singh I, Davim JP (2010) Neural network approach for estimate the residual tensile strength after drilling in uni-directional glass fiber reinforced plastic laminates. Mater Des 31:2790–2795

Geng D, Zhang D, Li Z, Liu D (2017) Feasibility study of ultrasonic elliptical vibrationassisted reaming of carbon fiber reinforced plastics/titanium alloy stacks. Ultrasonics 75:80–90

Tsao C (2008) Experimental study of drilling composite materials with step-core drill. Mater. Des 29:1740–1744

Krishnaraj V, Vijayarangan S, Suresh G (2005) An investigation on high speed drilling of glass fibre reinforced plastic (GFRP). Indian J. Eng. Mater. Sci 12:189–195

SenthilKumar M, Prabukarthi A, Krishnaraj V (2013) Study on tool wear and chip formation during drilling carbon fiber reinforced polymer (CFRP)/Titanium alloy (Ti6Al4V) stack. Proce. Eng 64:582–592

Isbilir O, Ghassemieh E (2013) Numerical investigation of the effects of drill geometry on drilling induced delamination of carbon fiber reinforced composites. Compos. Struct 105:126–133

Niketh S, Samuel GL (2016) Surface texturing for tribology enhancement and its application on drill tool for the sustainable machining of titanium alloy. J. Clean. Prod 167:253–270

Min S, Dornfeld DA, Nakao Y (2003) Influence of exit surface angle on drilling Burr formation. J Manuf Sci Eng 125(4):637–644

Kundu S, Das S, Saha PP (2014) Optimization of drilling parameters to minimize burr by providing back-up support on aluminium alloy. Procedia Engineering 97:230–240

Ni CB, Zhu LD, Liu CF, Yang ZC (2018) Analytical modeling of tool-workpiece contact rate and experimental study in ultrasonic vibration-assisted milling of Ti–6Al–4 V. Int J Mech Sci 142–143:97–111

Barani A, Amini S, Paktinat H, Tehrani AF (2014) Built-up edge investigation in vibration drilling of Al2024-T6. Ultrasonics 54(5):1300–1310

Amini S, Khosrojerdi M, Nosouhi R, Behbahani S (2014) An Experimental investigation on the machinability of Al2O3 in vibration-assisted turning using PCD tool. Mater. Manuf. Processes 29(3):331–336

Amini S, Paktinat H, Barani A, Tehran AF (2013) Vibration drilling of Al2024-T6. Mater. Manuf. Processes 28(4):476–480

Kong C, Wang DZ (2018) Numerical investigation of the performance of elliptical vibration cutting in machining of AISI 1045 steel. Int J Adv Manuf Technol 98(1–4):715–727

Chang SS, Bone GM (2005) Burr size reduction in drilling by ultrasonic assistance. Robot Comput Integr Manuf 21(4):442–450

Kadivar M et al (2012) Burr size reduction in drilling of Al/SiC metal matrix composite by ultrasonic assistance. Adv Mater Res 410:279–282

Wang YS, Sui LN, Yin ZY, Wang XL, Liu NN, Guo H (2017) A hybrid prediction for wind buffeting noises of vehicle rear window based on LES-LAA method. Appl Math Model 47:160–173

Paktinat HP, Amini S (2017) Ultrasonic assistance in drilling: FEM analysis and experimental approaches. Int J Adv Manuf Technol 92(5–8):2653–2665

Zhu ZJ, Guo K, Sun J, Li JF, Liu Y, Zheng YH, Chen L (2018) Evaluation of novel tool geometries in dry drilling aluminium 2024-T351/titanium Ti6AL4V stack. J Mater Process Tech 259:270–281

Kim J, Dornfeld DA (2002) Development of an analytical model for drilling burr formation in ductile materials. J Eng Mater Technol 124(2):192

Pujana J, Rivero A, Celaya A, Lo’pez de Lacalle LN (2009) Analysis of ultrasonic-assisted drilling of Ti6Al4V. Int J Mach Tools Manuf 49(6):500–508

Li R, Shih AJ (2007) Spiral point drill temperature and stress in high-throughput drilling of titanium. Int J Mach Tools Manuf 47(12-13):2005–2017

Bono M, Jun N (2002) A model for predicting the heat flow into the workpiece in dry drilling. J Manuf Sci Eng 124(4):773–777

Kalidas S, Kapoor SG, DeVor RE (2002) Influence of thermal effects on hole quality in dry drilling, Part 1: A thermal model of workpiece temperatures. J Manuf Sci Eng 124(2):258–266

Ueda T, Nozaki R, Hosokawa A (2007) Temperature measurement of cutting edge in drilling-effect of oil mist. CIRP Annals 56(1):93–96

Wei L, Wang D (2019) Comparative study on drilling effect between conventional drilling and ultrasonic-assisted drilling of Ti-6Al-4V/Al2024-T351 laminated material. Int J Adv Manuf Technol 103(1-4):141–152

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wei, L., Wang, D. Effect of ultrasound-assisted vibration on Ti-6Al-4V/Al2024-T351 laminated material processing with geometric tools. Int J Adv Manuf Technol 106, 219–232 (2020). https://doi.org/10.1007/s00170-019-04637-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04637-7