Abstract

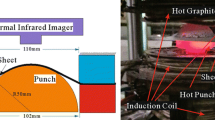

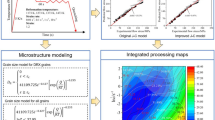

Flow stress curves of USIBOR1500 high-strength steel at high temperatures were obtained by tensile test. A constitutive model of high-temperature deformation of the material was established at 300–600 °C and 500–800 °C for one- and two-stage hot-forming processes, respectively. On the basis of the established constitutive equation, the one- and two-stage hot-forming methods were simulated, and the best process was determined. Results showed that the parts with simple shape and structure adopted the one-stage hot stamping technology, whereas the complicated parts adopted the two-stage hot stamping technology. The process parameters of the one-stage hot stamping technology are as follows: heating of the sheet material to more than 850 °C through an electric furnace, initial die temperature of 100 °C, stamping speed of 50 mm/s, pressing force of 1.28 kN, and punching pressure of 19.8 kN.

Similar content being viewed by others

References

Quan GZ, Wang T, Zhang L (2016) Research on the influence of hot stamping process parameters on phase field evolution by thermal-mechanical phase coupling finite element. Int J Adv Manuf Technol 89(1–4):1–17

Zhu B, Zhang Y, Li J, Wang H, Ye Z (2011) Simulation research of hot stamping and phase transition of automotive high strength steel. Mater Res Innov 15(s1):426–430

Ma N, Hu P, Shen G, Wu W (2010) Modeling, testing and numerical simulation on hot forming of HSS. American Institute of Physics, pp 18–26

Liu W, Liu HS, Xing Z, Liu G, Bao J (2012) Effect of tool temperature and punch speed on hot stamping of ultra high strength steel. Trans Nonferrous Metals Soc China 22:534–541

Liu H, Xing Z, Bao J, Song B (2010) Investigation of the hot-stamping process for advanced high-strength steel sheet by numerical simulation. J Mater Eng Perform 19(3):325–334

Liu H, Cui J, Jiang K, Zhou G (2016) Cracking prediction in hot stamping of high-strength steel by a temperature-dependent forming limit surface approach. J Mater Eng Performance 25(11):4894–4901

Sørensen P, Kiil S, Dam-Johansen K, Weinell C (2009) Influence of substrate topography on cathodic delamination of anticorrosive coatings. Prog Org Coat 64(2):142–149

Fang H, Wang G, Liu S, Liu X (2018) Research on resistance heating behavior of high-strength steel and its hot-stamping forming. J Mater Eng Performance 27(9):4829–4837

Merklein M, Lechler J (2006) Investigation of the thermo-mechanical properties of hot stamping steels. J Mater Process Tech 177(1–3):452–455

Mori K, Maki S, Tanaka Y (2005) Warm and hot stamping of ultra high tensile strength steel sheets using resistance heating. CIRP Ann Manuf Technol 54(1):209–212

Hoffmann H, So H, Steinbeiss H (2007) Design of hot stamping tools with cooling system. CIRP Ann Manuf Technol 56(1):269–272

Bardelcik A, Salisbury C, Winkler S, Wells M, Worswick M (2010) Effect of cooling rate on the high strain rate properties of boron steel. Int J Impact Eng 37(6):694–702

Åkerström P, Bergman G, Oldenburg M (2007) Numerical implementation of a constitutive model for simulation of hot stamping. Model Simul Mater Sci Eng 15(2):105–119

Naderi M, Uthaisangsuk V, Prahl U, Bleck W (2008) A numerical and experimental investigation into hot stamping of boron alloyed heat treated steel. Steel Res Int 79(2):77–84

Naderi M, Durrenberger L, Molinari A, Bleck W (2008) Constitutive relationships for 22MnB5 boron steel deformed isothermally at high temperatures. Mater Sci Eng A 478(1–2):130–139

Fan D, Park R, Cho Y, Cooman B (2010) Influence of isothermal deformation conditions on the mechanical properties of 22MnB5 HPF steel. Steel Res Int 81(4):292–298

Nikravesh M, Naderi M, Akbari G (2012) Influence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel. Mater Sci Eng A 540(4):24–29

Xue Y, Luo S, Luo J, Li Q (2017) Research on alternate bulge-forming process of spherical parts in near equal-thickness wall and strain field analysis. Int J Adv Manuf Technol 90:2325–2333

Zhan M, Yang H, Zhang J, Xu Y, Ma F (2007) 3D FEM analysis of influence of roller feed rate on forming force and quality of cone spinning. J Mater Process Technol 187-188:486–491

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, P., Zhu, L., Luo, S. et al. Hot stamping forming and finite element simulation of USIBOR1500 high-strength steel. Int J Adv Manuf Technol 103, 3187–3197 (2019). https://doi.org/10.1007/s00170-019-03727-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03727-w