Abstract

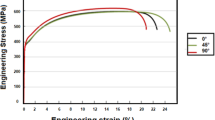

This paper studied the hot formability of the advanced high-strength steel B1500HS. The hot Nakazima tests were conducted to obtain the forming limit curve (FLC), and the sheet temperatures were recorded to analyze temperature distributions during deformation. Meanwhile, the numerical simulations of hot Nakazima tests were performed to compare with the experimental ones. By utilizing the commercial software, Abaqus, the punch force–displacement curve, sheet temperature distribution at the time of the maximum punch load and temperature path of the necked element were investigated from both of experiments and numerical simulations. The FLCs from experiment and numerical simulation showed a good agreement. The temperature path of the necked element on each FLC specimen was different due to the numerical stretching time and stress state. This study demonstrated the predictive capability of finite element simulation on hot stamping.

Similar content being viewed by others

References

H. Karbasian and A.E. Tekkaya, A Review on Hot Stamping, J. Mater. Process. Technol., 2010, 210(15), p 2103–2118

R.S. Lee, Y.K. Lin, T.W. Chien, Experimental and Theoretical Studies on Formability of 22MnB5 at Elevated Temperatures by Gleeble Simulator, The 11th International Conference on Technology of Plasticity, T. Ishikawa, K. Mori Eds., Oct 19–24, 2014 (Japan), 2014, p 1682–1688

J. Cui, C. Lei, Z. Xing, C. Li, and S. Ma, Predictions of the Mechanical Properties and Microstructure Evolution of High Strength Steel in Hot Stamping, J. Mater. Eng. Perform., 2012, 21(11), p 2244–2254

S.P. Keeler and W.A. Backofen, Plastic Instability and Fracture in Sheets Stretched Over Rigid Punches, ASM Trans. Q., 1963, 56(1), p 25–48

G.M. Goodwin, Application of strain analysis to sheet metal forming problems in the press shop, SAE Technical Paper 680093, 1968

K. Nakazima, T. Kikuma, K. Hasuka, Study on the formability of steel sheets, Yawata Tech Rep 264, 1968

Z. Marciniak, Limits of sheet metal formability, WNT, Warsaw in Polish, 1971

S. Panich, F. Barlat, V. Uthaisangsuk, S. Suranuntchai, and S. Jirathearanat, Experimental and Theoretical Formability Analysis Using Strain and Stress Based Forming Limit Diagram for Advanced High Strength Steels, Mater. Des., 2013, 51, p 756–766

H.W. Swift, Plastic Instability Under Plane Stress, J. Mech. Phys. Solids, 1952, 1(1), p 1–18

R. Hill, On Discontinuous Plastic States, with Special Reference to Localized Necking in Thin Sheets, J. Mech. Phys. Solids, 1952, 1(1), p 19–30

Z. Marciniak and K. Kuczyński, Limit Strains in the Processes of Stretch-Forming Sheet Metal, Int. J. Mech. Sci., 1967, 9(9), p 609–620

G. Mitukiewicz, K. Anantheshwara, G. Zhou, R. Mishra, and M. Jain, A New Method of Determining Forming Limit Diagram for Sheet Materials by Gas Blow Forming, J. Mater. Process. Technol., 2014, 214(12), p 2960–2970

L. Leotoing and D. Guines, Investigations of the Effect of Strain Path Changes on Forming Limit Curves Using an In-Plane Biaxial Tensile Test, Int. J. Mech. Sci., 2015, 99, p 21–28

T. Abovyan, G.T. Kridli, P.A. Friedman, and G. Ayoub, Formability Prediction of Aluminum Sheet Alloys Under Isothermal Forming Conditions, J. Manuf. Process., 2014, 20, p 406–413

M. Hajian and A. Assempour, Experimental and Numerical Determination of Forming Limit Diagram for 1010 Steel Sheet: A Crystal Plasticity Approach, Int. J. Adv. Manuf. Technol., 2015, 76(9), p 1–11

A. Martínez-Donaire, F. García-Lomas, and C. Vallellano, New Approaches to Detect the Onset of Localised Necking in Sheets Under Through-Thickness Strain Gradients, Mater. Des., 2014, 57, p 135–145

A. Turetta, S. Bruschi, and A. Ghiotti, Investigation of 22MnB5 Formability in Hot Stamping Operations, J. Mater. Process. Technol., 2006, 177(1-3), p 396–400

P. Bariani, S. Bruschi, A. Ghiotti, and A. Turetta, Testing Formability in the Hot Stamping of HSS, CIRP Ann-Manuf. Technol., 2008, 57(1), p 265–268

Y. Dahan, Y. Chastel, P. Duroux, J. Wilsius, P. Hein, E. Massoni, Procedure for the experimental determination of a forming limit curve for USIBOR 1500P, International Deep Drawing Research Group, M. Tisza Ed., May 21–23, 2007 (Gyor-Hungary), 2007

D. Shi, L. Ying, P. Hu, J. Lu, X. Zhao, W. Liu, Experimental and numerical determination of thermal forming limit diagrams (TFLD) of high strength steel 22MnB5, The 11th International Conference on Numerical Methods in Industrial Forming Processes: NUMIFORM 2013, S. Zhang, X. Liu, M. Cheng, J. Li Eds., Jul 6–10, 2013 (China), AIP, 2013, p 406–413

F.F. Li, M.W. Fu, J.P. Lin, and X.N. Wang, Experimental and Theoretical Study on the Hot Forming Limit of 22MnB5 Steel, Int. J. Adv. Manuf. Technol., 2014, 71(1), p 297–306

J. Min, J. Lin, J. Li, and W. Bao, Investigation on Hot Forming Limits of High Strength Steel 22MnB5, Comput. Mater. Sci., 2010, 49(2), p 326–332

H. Li, X. Wu, and G. Li, Prediction of Forming Limit Diagrams for 22MnB5 in Hot Stamping Process, J. Mater. Eng. Perform., 2013, 22(8), p 2131–2140

J. Cui, G. Sun, J. Xu, X. Huang, and G. Li, A Method to Evaluate the Formability of High-Strength Steel in Hot Stamping, Mater. Des., 2015, 77(15), p 95–109

K. Kusumi, N. Nomura, S. Yamamoto, M. Nakata, M. Abe, M. Suehiro, Improvement of Cylindrical Deep Drawability in Hot Stamping, The 11th International Conference on Technology of Plasticity, T. Ishikawa, K. Mori Eds., Oct 19–24, 2014 (Japan), 2014, p 1719–1724

M.H.F. Batalha and S.T. Button, Hot Formability of DIN 27MnCrB5 Steel Sheets Under Controlled Thinning, J. Mater. Process. Technol., 2016, 228, p 98–105

J. Liu, Q. Peng, Y. Liu, and Z. Wang, Viscous Pressure Bulging of Aluminium Alloy Sheet at Warm Temperatures, J. Mech. Sci. Technol., 2007, 21(10), p 1505–1511

A. Blaise, B. Bourouga, B. Abdulhay, and C. Dessain, Thermal Contact Resistance Estimation and Metallurgical Transformation Identification During the Hot Stamping, Appl. Therm. Eng., 2013, 61(2), p 141–148

B. Abdulhay, B. Bourouga, C. Dessain, G. Brun, and J. Wilsius, Experimental Study of Heat Transfer in Hot Stamping Process, Int. J. Mater. Form., 2009, 2(1), p 255–257

B. Abdulhay, B. Bourouga, and C. Dessain, Experimental and Theoretical Study of Thermal Aspects of the Hot Stamping Process, Appl. Therm. Eng., 2011, 31(5), p 674–685

B. Ma, W. Yuan, X. Wu, X. Li, and M. Wan, Study on Temperature Distribution of HSS in Hot FLD Test, Appl. Therm. Eng., 2015, 89, p 144–155

B. Ma, K. Diao, X. Wu, X. Li, M. Wan, and Z. Cai, The Effect of the Through-Thickness Normal Stress on Sheet Formability, J. Manuf. Process., 2016, 21, p 134–140

B. Ma, X. Wu, X. Li, M. Wan, and Z. Cai, Investigation on the Hot Formability of TA15 Titanium Alloy Sheet, Mater. Des., 2016, 94, p 9–16

R. Grueebler and P. Hora, Temperature Dependent Friction Modeling for Sheet Metal Forming, Int. J. Mater. Form., 2009, 2(1), p 251–254

W. Liang, L. Wang, Y. Liu, Y. Wang, Y. Zhang, Hot Stamping Parts with Tailored Properties by Local Resistance Heating, The 11th International Conference on Technology of Plasticity, T. Ishikawa, K. Mori Eds., Oct 19–24, 2014 (Japan), 2014, p 1731–1736

Acknowledgments

The authors would like to give thanks for the supports from the National Nature Science Foundation of China (No. 51275026), the State Key Laboratory of Development and Application Technology of Automotive Steels (Baosteel Group) and the Academic Excellence Foundation of BUAA for PhD student.

Funding

This study was funded by The National Nature Science Foundation of China (No. 51275026), The State Key Laboratory of Development and Application Technology of Automotive Steels (No. Null) and The Academic Excellence Foundation of BUAA for Ph.D. Student (No. Null).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Author M. Wan has received research Grants from The National Nature Science Foundation of China. The State Key Laboratory of Development and Application Technology of Automotive Steels has funded author X.D. Wu. Author B.L. Ma has gotten the financial support from The Academic Excellence Foundation of BUAA. Author D.K. Shan is placed in charge of The State Key Laboratory of Development and Application Technology of Automotive Steels. Author X.J. Li is the supervisor of author B.L. Ma. Author Z.G. Liu improves the English writing with us.

Rights and permissions

About this article

Cite this article

Ma, B.L., Wan, M., Liu, Z.G. et al. Experimental and Numerical Determination of Hot Forming Limit Curve of Advanced High-Strength Steel. J. of Materi Eng and Perform 26, 3299–3306 (2017). https://doi.org/10.1007/s11665-017-2751-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2751-2