Abstract

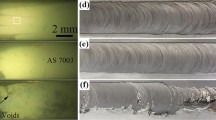

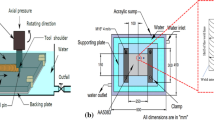

This paper deals for the first time with the effects of additional cooling medium by submerging underwater on the feasibility of dissimilar bond formation between aluminum and steel in solid-state during friction-stir welding (FSW) process. Sheets of AA5083 Al-Mg aluminum alloy and A441 AISI steel are considered into the investigation with a butt-joint design and immersing under the cooling water mediums with three different temperatures of 0, 25, and 50 °C besides ambient processing in the air atmosphere without excessive cooling. Thermo-mechanical cycles during the FSW process are monitored as well as the soundness of produced dissimilar weldments in terms of materials inter-mixing, grain structural features, possible phase transformations, mechanical property, and subsequent fracture behavior. The results showed that by increasing the cooling capability of the environment and employing the low-temperature water as the submerged medium, the peak temperature during the FSW process is continuously reduced down to ~ 400 °C. The impact influence is on suppressing the dissimilar metals inter-mixing as well as the grain structural coarsening during dynamic recrystallization and the kinetics of intermetallic compound (IMC) formation. By decreasing the peak temperature and submerging under cooling medium, the thickness of the IMC layer at the interface is continuously decreased as affected the indentation hardness resistance and subsequent transverse tensile behavior. All samples are failed at the joint interface along the IMC layer, with an excellent combination of tensile strength (~ 310 MPa) and elongation (~ 13%) for the room temperature cooling medium, as the optimum condition based on the evolution of experimental trends. The dominant flow mechanism as plastic constraint induced some fractural aspects of ductile in dimpler form or catastrophic on the corresponding failed portion depending on the joint brittleness.

Similar content being viewed by others

References

Derazkola HA, Khodabakhshi F, Simchi A (2018) Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: thermo-mechanical modelling and experimental feasibility study. Sci Technol Weld Join 23(1):35–49

Khodabakhshi F, Arab SM, Švec P, Gerlich AP (2017) Fabrication of a new Al-Mg/graphene nanocomposite by multi-pass friction-stir processing: dispersion, microstructure, stability, and strengthening. Mater Charact 132:92–107

Khodabakhshi F, Gerlich AP, Švec P (2017) Fabrication of a high strength ultra-fine grained Al-Mg-SiC nanocomposite by multi-step friction-stir processing. Mater Sci Eng A 698:313–325

Derazkola HA, Aval HJ, Elyasi M (2015) Analysis of process parameters effects on dissimilar friction stir welding of AA1100 and A441 AISI steel. Sci Technol Weld Join 20(7):553–562

Çam G (2011) Friction stir welded structural materials: beyond Al-alloys. Int Mater Rev 56(1):1–48

Çam G, İpekoğlu G (2017) Recent developments in joining of aluminum alloys. Int J Adv Manuf Technol 91(5):1851–1866

Çam G, Ipekoglu G, Küçükömeroglu T, Aktarer SM (2017) Applicability of friction stir welding to steels. J Achiev Mater Manuf Eng 2(80):65–85

Çam G, Mistikoglu S (2014) Recent developments in friction stir welding of Al-alloys. J Mater Eng Perform 23(6):1936–1953

Kashaev N, Ventzke V, Çam G (2018) Prospects of laser beam welding and friction stir welding processes for aluminum airframe structural applications. J Manuf Process 36:571–600

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R50(1–2):1–78

Rafiei R, Moghaddam AO, Hatami M, Khodabakhshi F, Abdolahzadeh A, Shokuhfar A (2017) Microstructural characteristics and mechanical properties of the dissimilar friction-stir butt welds between an Al–Mg alloy and A316L stainless steel. Int J Adv Manuf Technol 90(9–12):2785–2801

Rafiei R, Shamanian M, Fathi MH, Khodabakhshi F (2018) Dissimilar friction-stir lap-welding of aluminum-magnesium (AA5052) and aluminum-copper (AA2024) alloys: microstructural evolution and mechanical properties. Int J Adv Manuf Technol 94(9):3713–3730

Khodabakhshi F, Haghshenas M, Sahraeinejad S, Chen J, Shalchi B, Li J, Gerlich AP (2014) Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater Charact 98:73–82

Khodabakhshi F, Haghshenas M, Chen J, Shalchi Amirkhiz B, Li J, Gerlich AP (2017) Bonding mechanism and interface characterisation during dissimilar friction stir welding of an aluminium/polymer bi-material joint. Sci Technol Weld Join 22(3):182–190

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2016) Similar and dissimilar friction-stir welding of an PM aluminum-matrix hybrid nanocomposite and commercial pure aluminum: microstructure and mechanical properties. Mater Sci Eng A 666:225–237

Khodabakhshi F, Ghasemi Yazdabadi H, Kokabi AH, Simchi A (2013) Friction stir welding of a P/M Al-Al2O3 nanocomposite: microstructure and mechanical properties. Mater Sci Eng A 585:222–232

Khodabakhshi F, Simchi A (2017) The role of microstructural features on the electrical resistivity and mechanical properties of powder metallurgy Al-SiC-Al2O3 nanocomposites. Mater Des 130:26–36

Khodabakhshi F, Simchi A, Kokabi A, Gerlich A, Nosko M, Švec P (2017) Influence of hard inclusions on microstructural characteristics and textural components during dissimilar friction-stir welding of an PM Al–Al2O3–SiC hybrid nanocomposite with AA1050 alloy. Sci Technol Weld Join 22(5):412–427

Aghajani Derazkola H, Simchi A (2018) Experimental and thermomechanical analysis of friction stir welding of poly(methyl methacrylate) sheets. Sci Technol Weld Join 23(3):209–218

Derazkola HA, Kashiry Fard R, Khodabakhshi F (2018) Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer. Weld World 62(1):117–130

Elyasi M, Derazkola HA, Hosseinzadeh M (2016) Investigations of tool tilt angle on properties friction stir welding of A441 AISI to AA1100 aluminium. Proc Inst Mech Eng B J Eng Manuf 230(7):1234–1241

Mendes A, Timokhina I, Molotnikov A, Hodgson PD, Lapovok R (2017) Role of shear in interface formation of aluminium-steel multilayered composite sheets. Mater Sci Eng A 705:142–152

Zhang H, Liu H (2012) Characteristics and formation mechanisms of welding defects in underwater friction stir welded aluminum alloy. Metall Microstruct Anal 1(6):269–281

Liu HJ, Zhang HJ, Yu L (2011) Effect of welding speed on microstructures and mechanical properties of underwater friction stir welded 2219 aluminum alloy. Mater Des 32(3):1548–1553

Zhang H, Liu H (2013) Mathematical model and optimization for underwater friction stir welding of a heat-treatable aluminum alloy. Mater Des 45:206–211

Sree Sabari S, Malarvizhi S, Balasubramanian V, Madusudhan Reddy G (2016) Experimental and numerical investigation on under-water friction stir welding of armour grade AA2519-T87 aluminium alloy. Def Technol 12(4):324–333

Heirani F, Abbasi A, Ardestani M (2017) Effects of processing parameters on microstructure and mechanical behaviors of underwater friction stir welding of Al5083 alloy. J Manuf Process 25:77–84

Liang H, Yan K, Wang Q, Zhao Y, Liu C, Zhang H (2016) Improvement in joint strength of spray-deposited Al-Zn-Mg-Cu alloy in underwater friction stir welding by altered temperature of cooling water. J Mater Eng Perform 25(12):5486–5493

Wang Q, Zhao Z, Zhao Y, Yan K, Zhang H (2015) The adjustment strategy of welding parameters for spray formed 7055 aluminum alloy underwater friction stir welding joint. Mater Des 88:1366–1376

Papahn H, Bahemmat P, Haghpanahi M, Sommitsch C (2015) Study on governing parameters of thermal history during underwater friction stir welding. Int J Adv Manuf Technol 78(5):1101–1111

Tan YB, Wang XM, Ma M, Zhang JX, Liu WC, Fu RD, Xiang S (2017) A study on microstructure and mechanical properties of AA 3003 aluminum alloy joints by underwater friction stir welding. Mater Charact 127:41–52

Bijanrostami K, Barenji RV, Hashemipour M (2017) Effect of traverse and rotational speeds on the tensile behavior of the underwater dissimilar friction stir welded aluminum alloys. J Mater Eng Perform 26(2):909–920

Zhao Y, Jiang S, Yang S, Lu Z, Yan K (2016) Influence of cooling conditions on joint properties and microstructures of aluminum and magnesium dissimilar alloys by friction stir welding. Int J Adv Manuf Technol 83(1):673–679

Zhao Y, Lu Z, Yan K, Huang L (2015) Microstructural characterizations and mechanical properties in underwater friction stir welding of aluminum and magnesium dissimilar alloys. Mater Des (1980-2015) 65:675–681

Zhang J, Shen Y, Yao X, Xu H, Li B (2014) Investigation on dissimilar underwater friction stir lap welding of 6061-T6 aluminum alloy to pure copper. Mater Des 64:74–80

Çam G, Güçlüer S, Çakan A, Serindag HT (2009) Mechanical properties of friction stir butt-welded Al-5086 H32 plate. Mater Werkst 40(8):638–642

Küçükömeroğlu T, Aktarer SM, İpekoğlu G, Cam G (2018) Mechanical properties of friction stir welded St 37 and St 44 steel joints. Mater Test 60(12):1163–1170

Küçükömeroğlu T, Aktarer SM, İpekoğlu G, Çam G (2018) Microstructure and mechanical properties of friction-stir welded St52 steel joints. Int J Miner Metall Mater 25(12):1457–1464

İpekoğlu G, Küçükömero T, Aktarer SM, Sekban DM, Çam G (2019) Investigation of microstructure and mechanical properties of friction stir welded dissimilar St37/St52 joints. Mater Res Exp 6(4):046537

Hamilton C, Dymek S, Blicharski M (2008) A model of material flow during friction stir welding. Mater Charact 59(9):1206–1214

Neto DM, Neto P (2013) Numerical modeling of friction stir welding process: a literature review. Int J Adv Manuf Technol 65(1):115–126

Hamilton C, Dymek S, Sommers A (2008) A thermal model of friction stir welding in aluminum alloys. Int J Mach Tools Manuf 48(10):1120–1130

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP, Nosko M (2015) Effects of stored strain energy on restoration mechanisms and texture components in an aluminum–magnesium alloy prepared by friction stir processing. Mater Sci Eng A 642:204–214

Wahid MA, Khan ZA, Siddiquee AN (2018) Review on underwater friction stir welding: a variant of friction stir welding with great potential of improving joint properties. Trans Nonferrous Met Soc China 28(2):193–219

Khodabakhshi F, Simchi A, Kokabi A (2017) Surface modifications of an aluminum-magnesium alloy through reactive stir friction processing with titanium oxide nanoparticles for enhanced sliding wear resistance. Surf Coat Technol 309:114–123

Khodabakhshi F, Simchi A, Kokabi AH, Gerlich AP (2015) Friction stir processing of an aluminum-magnesium alloy with pre-placing elemental titanium powder: in-situ formation of an Al3Ti-reinforced nanocomposite and materials characterization. Mater Charact 108:102–114

Khodabakhshi F, Marzbanrad B, Jahed H, Gerlich AP (2018) Interfacial bonding mechanisms between aluminum and titanium during cold gas spraying followed by friction-stir modification. Appl Surf Sci 462:739–752

Khodabakhshi F, Haghshenas M, Eskandari H, Koohbor B (2015) Hardness−strength relationships in fine and ultra-fine grained metals processed through constrained groove pressing. Mater Sci Eng A 636:331–339

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Derazkola, H.A., Khodabakhshi, F. Underwater submerged dissimilar friction-stir welding of AA5083 aluminum alloy and A441 AISI steel. Int J Adv Manuf Technol 102, 4383–4395 (2019). https://doi.org/10.1007/s00170-019-03544-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03544-1