Abstract

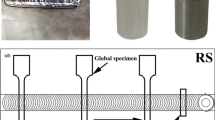

The aim of this work is to investigate the mechanical properties and microstructures of friction-stir welded (FSWed) St52 structural steel joints. In this study, St52 steel plates with a thickness of 4 mm were butt-welded by friction-stir welding (FSW) using a tungsten carbide tool having a conical pin. The microstructure of the welded zone consists of equiaxed fine ferrite, grain boundary ferrite, Widmanstatten ferrite, and aggregates of ferrite + cementite. The microhardness measurements showed that the hardness of the welded zone was significantly higher than that of the base metal. The FSWed St52 joint exhibited a significant strength overmatching in the weld region and a strength performance similar to or slightly higher than that of the base plate.

Similar content being viewed by others

References

W.M.N. Thomas, E.D. Nicholas, C. Needham, M.G. Murch, P. Templesmith, and C.J. Dawes, Friction Stir Butt Welding, Int. Patent Appl. PCT/GB92/02203 and GB Patent Appl. 9125978.8, 1991, and US Patent Appl. 5460317, 1995.

R.S. Mishra and Z.Y. Ma, Friction stir welding and processing, Mater. Sci. Eng. R, (50)2005, No. 1–2, p. 1.

G. Çam and G. İpekoğlu, Recent developments in joining of aluminium alloys, Int. J. Adv. Manuf. Technol., 91(2017), No. 5–8, p. 1851.

G. Çam, Friction stir welded structural materials: beyond Al–alloys, Int. Mater. Rev., 56(2011), No. 1, p. 1.

G. Çam, G. İpekoğlu, T. Küçükömeroğlu, and S.M. Aktarer, Applicability of friction stir welding to steels, J. Achv. Mater. Manuf. Eng., 80(2017), No. 2, p. 65.

R. Nandan, T. DebRoy, and H.K.D.H. Bhadeshia, Recent advances in friction–stir welding–Process, weldment structure and properties, Prog. Mater. Sci., 53(2008), No. 6, p. 980.

J.A. Esparza, W.C. Davis, E.A. Trillo, and L.E. Murr, Friction–stir welding of magnesium alloy AZ31B, J. Mater. Sci. Lett., 21(2002), No. 12, p. 917.

S. Rajakumar, A. Razalrose, and V. Balasubramanian, Friction stir welding of AZ61A magnesium alloy, Int. J. Adv. Manuf. Technol., 68(2013), No. 1–4, p. 277.

Y. Templeman, G.B. Hamu, and L. Meshi, Friction stir welded AM50 and AZ31Mg alloys: Microstructural evolution and improved corrosion resistance, Mater. Charact., 126(2017), p. 86.

W.M. Thomas, P.L. Threadgill, and E.D. Nicholas, Feasibility of friction stir welding steel, Sci. Technol. Weld. Joining, 4(1999), No. 6, p. 365.

M. Jafari, M. Abbasi, D. Poursina, A. Gheysarian, and B. Bagheri, Microstructures and mechanical properties of friction stir welded dissimilar steel–copper joints, J. Mech. Sci. Technol., 31(2017), No. 3, p. 1135.

F.C. Liu, Y. Hovanski, M.P. Miles, C.D. Sorensen, and T.W. Nelson, A review of friction stir welding of steels: Tool, material flow, microstructure, and properties, J. Mater. Sci. Techol., (34)2018, No. 1, p. 39.

H.H. Liu and H. Fujii, Microstructural and mechanical properties of a beta–type titanium alloy joint fabricated by friction stir welding, Mater. Sci. Eng. A, 711(2018), p. 140.

S. Mironov, Y.S. Sato, and H. Kokawa, Friction–stir welding and processing of Ti−6Al−4V titanium alloy: A review, J. Mater. Sci. Techol., 34(2018), No. 1, p. 58.

P. Edwards and M. Ramulu, Fatigue performance of friction stir welded titanium structural joints, Int. J. Fatigue, 70(2015), p. 171.

H. Fujii, L. Cui, N. Tsuji, M. Maeda, K. Nakata, and K. Nogi, Friction stir welding of carbon steels, Mater. Sci. Eng. A, 429(2006), No. 1–2, p. 50.

T.J. Lienert, W.L. Stellwag, B.B. Grimmett, and R.W. Warke, Friction stir welding studies on mild steel − Process results, microstructures, and mechanical properties are reported, Weld. J., 82(2003), No. 1, p. 1–S.

L. Cui, H. Fujii, N. Tsuji, and K. Nogi, Friction stir welding of a high carbon steel, Scripta Mater., 56(2007), No. 7, p. 637.

M. Imam, R. Ueji, and H. Fujii, Microstructural control and mechanical properties in friction stir welding of medium carbon low alloy S45C steel, Mater. Sci. Eng. A, 636(2015), p. 24.

H. Fujii, R. Ueji, Y. Takada, H. Kitahara, N. Tsuji, K. Nakata, and K. Nogi, Friction stir welding of ultrafine grained interstitial free steels, Mater. Trans., 47(2006), No. 1, p. 239.

L.F. Cui, H. Fujii, N. Tsuji, K. Nakata, K. Nogi, R. Ikeda, and M. Matsushita, Transformation in stir zone of friction stir welded carbon steels with different carbon contents, ISIJ Int., 47(2007), No. 2, p. 299.

A.J. Ozekcin, H.W. Jin, J.Y. Koo, N.V. Bangaru, R. Ayer, G. Vaughn, R. Steel, and S. Packer, A microstructural study of friction stir welded joints of carbon steels, Int. J. Offshore Polar Eng., 14(2004). No. 4, p. 284.

D.H. Choi, C.Y. Lee, B.W. Ahn, Y.M. Yeon, S.H.C. Park, Y.S. Sato, H. Kokowa, and S.B. Jung, Effect of fixed location variation in friction stir welding of steels with different carbon contents, Sci. Technol. Weld. Joining, 15(2010), No. 4, p. 299.

D.H. Choi, B.W. Ahn, Y.M. Yeon, S.H.C. Park, Y.S. Sato, H. Kokowa, and S.B. Jung, Microstructural characterizations following friction stir welding of dissimilar alloys of low–and high–carbon steels, Mater. Trans., 52(2011), No. 7, p. 1500.

P.L. Threadgill, Terminology in friction stir welding, Sci. Technol. Weld. Joining, 12(2007), No. 4, p. 357.

P. Movahed, S. Kolahgar, S.P.H. Marashi, M. Pouranvari, and N. Parvin, The effect of intercritical heat treatment temperature on the tensile properties and work hardening behavior of ferrite–martensite dual phase steel sheets, Mater. Sci. Eng. A, 518(2009), No. 1–2, p. 1.

G. Thewlis, Classification and quantification of microstructures in steels, Mater. Sci. Techol., 20(2004), No. 2, p. 143.

M. Jafarzadegan, A.H. Feng, A. Abdollah–zadeh, T. Saeid, J. Shen, and H. Assadi, Microstructural characterization in dissimilar friction stir welding between 304 stainless steel and St37 steel, Mater. Charact., 74(2012), p. 28.

G. Çam, Ç. Yeni, S. Erim, V. Ventzke, and M. Koçak, Investigation into properties of laser welded similar and dissimilar steel joints, Sci. Technol. Weld. Joining, 3(1998), No. 4, p. 177.

G. Çam, G. İpekoğlu, and H.T. Serindağ, Effects of use of higher strength interlayer and external cooling on properties of friction stir welded AA6061–T6 joints, Sci. Technol. Weld. Joining, 19(2014), No. 8, p. 715.

G. İpekoğlu, S. Erim, and G. Çam, Investigation into the influence of post–weld heat treatment on the friction stir welded AA6061 Al–alloy plates with different temper conditions, Metall. Mater. Trans. A, 45(2014), No. 2, p. 864.

G. İpekoğlu, S. Erim, B. G. Kıral, and G. Çam, Investigation into the effect of temper condition on friction stir weldability of AA6061 Al–alloy plates, Kovove Mater., 51(2013), No. 3, p. 155.

G. İpekoğlu, B.G. Kıral, S. Erim, and G. Çam, Investigation of the effect of temper condition on friction stir weldability of AA7075 Al–alloy plates, Mater. Tehnol., 46(2012), No. 6, p. 627.

G. Çam, S. Güçlüer, A. Çakan, and H.T. Serindağ, Mechanical properties of friction stir butt–welded Al–5086H32 plate, Materialwiss. Werkstofftech., 40(2009), No. 8, p. 638.

G. Çam, V. Ventzke, J.F. Dos Santos, M. Koçak, G. Jennequin, P. Gonthier–Maurin, M. Penasa, and C. Rivezla, Characterization of laser and electron beam welded Al–alloys, Prakt. Metallogr., 37(2000), No. 2, p. 59.

G. Çam, V. Ventzke, J.F. Dos Santos, M. Koçak, G. Jennequin, and P. Gonthier–Maurin, Characterisation of electron beam welded aluminium alloys, Sci. Technol. Weld. Joining, 4(1999), No. 5, p. 317.

T. Küçükömeroğlu, E. Şentürk, L. Kara, G. İpekoğlu, and G. Çam, Microstructural and mechanical properties of friction stir welded nickel–aluminum bronze (NAB) alloy, J. Mater. Eng. Perform., 25(2016,) No. 1, p. 320.

G. Çam, S. Mistikoglu, and M. Pakdil, Microstructural and mechanical characterization of friction stir butt joint welded 63%Cu−37%Zn brass plate, Weld. J., 88(2009), No. 11, p. 225S.

G. Çam, H.T. Serindag, A. Çakan, S. Mistikoglu, and H. Yavuz, The effect of weld parameters on friction stir welding of brass plates, Materialwiss. Werkstofftech., 39(2008), No. 6, p. 394.

X.C. He, F.S. Gu, and A. Ball, A review of numerical analysis of friction stir welding, Prog. Mater. Sci., 65(2014), p. 1.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Küçükömeroğlu, T., Aktarer, S.M., İpekoğlu, G. et al. Microstructure and mechanical properties of friction-stir welded St52 steel joints. Int J Miner Metall Mater 25, 1457–1464 (2018). https://doi.org/10.1007/s12613-018-1700-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1700-x