Abstract

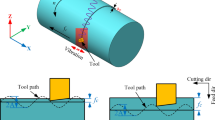

The cavitation characteristics involved in ultrasonic-assisted abrasive waterjet were analyzed in the present study. The fluid field corresponding to ultrasonic-assisted AWJ was investigated through utilizing computational fluid dynamics. A cavitation model was adopted to simulate the mass transfer between water liquid and vapor phases. The evolution of cavitation during the impacting process and the effects of vibration parameters on cavitating characteristics were investigated. Moreover, a set of experiments were performed to evaluate the effects of ultrasonic-induced cavitation on erosion and material removal of ceramics. The results indicated that the evolution of cavitation had dependency on the fluid pressure and turbulence at impacted zone, and the synergetic erosion of microjets and accelerated particles induced by collapsing cavitation bubbles can evidently enhance the material removal. The material removal rate was improved by 82% at most under ultrasonic vibration.

Similar content being viewed by others

References

Li HZ, Wang J, Fan JM (2009) Analysis and modelling of particle velocities in micro-abrasive air jet. Int J Mach Tools Manuf 49:850–858. https://doi.org/10.1016/j.ijmachtools.2009.05.012

Fan JM, Li HZ, Wang J, Wang CY (2011) A study of the flow characteristics in micro-abrasive jets. Exp Thermal Fluid Sci 35:1097–1106. https://doi.org/10.1016/j.expthermflusci.2011.03.004

Hloch S, Valíček J (2012) Topographical anomaly on surfaces created by abrasive waterjet. Int J Adv Manuf Technol 59:593–604. https://doi.org/10.1007/s00170-011-3511-3

Valíček J, Držík M, Hloch S, Ohlídal M, Miloslav L, Gombár M, Radvanská A, Hlaváček P, Páleníková K (2007) Experimental analysis of irregularities of metallic surfaces generated by abrasive waterjet. Int J Mach Tools Manuf 47:1786–1790. https://doi.org/10.1016/j.ijmachtools.2007.01.004

Lehocka D, Klich J, Foldyna J, Hloch S, Krolczyk JB, Carach J, Krolczyk GM (2016) Copper alloys disintegration using pulsating water jet. Meas J Int Meas Confed 82:375–383. https://doi.org/10.1016/j.measurement.2016.01.014

Lv Z, Hou R, Huang C, Zhu H, Wang J (2018) Investigation on erosion mechanism in ultrasonic assisted abrasive waterjet machining. Int J Adv Manuf Technol 94:3741–3755. https://doi.org/10.1007/s00170-017-0995-5

Lv Z, Hou R, Tian Y, Huang C, Zhu H (2018) Investigation on flow field of ultrasonic-assisted abrasive waterjet using CFD with discrete phase model. Int J Adv Manuf Technol 96:963–972. https://doi.org/10.1007/s00170-018-1635-4

Qi H, Wen D, Lu C, Li G (2016) Numerical and experimental study on ultrasonic vibration-assisted micro-channelling of glasses using an abrasive slurry jet. Int J Mech Sci 110:94–107. https://doi.org/10.1016/j.ijmecsci.2016.03.013

Qi H, Wen D, Yuan Q, Zhang L, Chen Z (2017) Numerical investigation on particle impact erosion in ultrasonic-assisted abrasive slurry jet micro-machining of glasses. Powder Technol 314:627–634. https://doi.org/10.1016/j.powtec.2016.08.057

Soyama H (2013) Effect of nozzle geometry on a standard cavitation erosion test using a cavitating jet. Wear 297:895–902. https://doi.org/10.1016/j.wear.2012.11.008

Li D, Kang Y, Wang X, Ding X, Fang Z (2016) Effects of nozzle inner surface roughness on the cavitation erosion characteristics of high speed submerged jets. Exp Thermal Fluid Sci 74:444–452. https://doi.org/10.1016/j.expthermflusci.2016.01.009

Liu H, Kang C, Zhang W, Zhang T (2017) Flow structures and cavitation in submerged waterjet at high jet pressure. Exp Thermal Fluid Sci 88:504–512. https://doi.org/10.1016/j.expthermflusci.2017.07.003

Beaucamp A, Katsuura T, Kawara Z (2017) A novel ultrasonic cavitation assisted fluid jet polishing system. CIRP Ann - Manuf Technol 66:301–304. https://doi.org/10.1016/j.cirp.2017.04.083

Chen F, Wang H, Tang Y, Yin S, Huang S, Zhang G (2018) Novel cavitation fluid jet polishing process based on negative pressure effects. Ultrason Sonochem 42:339–346. https://doi.org/10.1016/j.ultsonch.2017.11.016

Kowsari K, Amini MH, Papini M, Spelt JK (2016) The effects of fluid vapor pressure and viscosity on the shapes of abrasive slurry-jet micro-machined holes and channels. Int J Mach Tools Manuf 110:80–91. https://doi.org/10.1016/j.ijmachtools.2016.09.004

Marcon A, Melkote SN, Yoda M (2018) Effect of nozzle size scaling in co-flow water cavitation jet peening. J Manuf Process 31:372–381. https://doi.org/10.1016/j.jmapro.2017.12.002

Singhal AK, Athavale MM, Li H, Jiang Y (2002) Mathematical basis and validation of the full cavitation model. J Fluids Eng 124:617. https://doi.org/10.1115/1.1486223

Lv Z, Huang C, Zhu H, Wang J, Hou R (2016) A 3D simulation of the fluid field at the jet impinging zone in ultrasonic-assisted abrasive waterjet polishing. Int J Adv Manuf Technol 87:3091–3103. https://doi.org/10.1007/s00170-016-8722-1

Funding

This work is supported by National Natural Science Foundation of China (51405274).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lv, Z., Hou, R., Wang, T. et al. Research on cavitation involved in ultrasonic-assisted abrasive waterjet machining. Int J Adv Manuf Technol 101, 1879–1886 (2019). https://doi.org/10.1007/s00170-018-3103-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-3103-6