Abstract

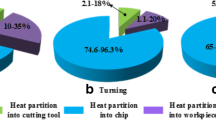

Lots of heat generated in the cutting deformation zone can cause the temperature rising of cutting tool and workpiece during the cutting process. Tool temperature is mainly depended on the heat energy entering into tool in the secondary deformation zone. Higher working temperature can weaken the cutting tool strength and then deteriorate the tool wear. Advanced coating layer deposited on the tool substrate can change the tool-chip friction and affect the heat partition in the tool-chip interface. In order to reveal the mechanism of heat conduction in the secondary deformation zone, the model of heat partition into cutting tool was built. With the aid of finite element method (FEM), the relative parameters which were necessary for the solving of heat partition model were quantified. Actual cutting experiments were carried out to the verification of the FEM models by means of the cutting force and temperature measurement. Influences of coatings (i.e., coating materials, coating thickness) and cutting speeds on the heat partition were analyzed. And then, rake face temperatures obtained at four kinds of coated tools were compared. The investigation results showed that TiC coating appears as the maximum value and Al2O3 coating appears as the minimum value of heat partition coefficient into cutting tool among these four kinds of coatings (i.e., TiC, TiN, TiAlN, Al2O3). With the increasing of coating thickness and cutting speeds, heat partition into cutting tool all showed a decrease trend. Al2O3-coated tool had the maximum rake face temperature among these four kinds of coated tools; however, the location of peak temperature on the rake face of Al2O3-coated tool was the shortest distance from the tool tip.

Similar content being viewed by others

References

Abukhshim NA, Mativenga PT, Sheikh MA (2006) Heat generation and temperature prediction in metal cutting: a review and implications for high speed machining. Int J Mach Tool Manuf 46(7):782–800

Grzesik W, Nieslony P (2003) A computational approach to evaluate temperature and heat partition in machining with multilayer coated tools. Int J Mach Tool Manuf 43(13):1311–1317

Le CG, Dudzinski D (2014) Temperature variation in the workpiece and in the cutting tool when dry milling Inconel 718. Int J Adv Manuf Technol 74(5–8):1133–1139

Rech J, Battaglia JL, Moisan A (2005) Thermal influence of cutting tool coatings. J Mater Process Technol 159(1):119–124

Bouzakis KD, Vidakis N, Leyendecker T, Lemmer O, Fuss HG, Erkens G (1996) Determination of the fatigue behaviour of thin hard coatings using the impact test and a FEM simulation. Surf Coat Technol 86:549–556

Cui X, Zhao J (2014) Cutting performance of coated carbide tools in high-speed face milling of AISI H13 hardened steel. Int J Adv Manuf Technol 71(9–12):1811–1824

Chinchanikar S, Choudhury SK (2016) Cutting force modeling considering tool wear effect during turning of hardened AISI 4340 alloy steel using multi-layer TiCN/Al2O3/TiN-coated carbide tools. Int J Adv Manuf Technol 83(9–12):1749–1762

Yan S, Zhu D, Zhuang K, Zhang X, Ding H (2014) Modeling and analysis of coated tool temperature variation in dry milling of Inconel 718 turbine blade considering flank wear effect. J Mater Process Technol 214(12):2985–3001

Dos Santos JABO, Sales WF, Santos SC, Machado AR, da Silva MB, Bonney J, Ezugwu EO (2007) Tribological evaluation of TiN and TiAlN coated PM-HSS gear cutter when machining 19MnCr5 steel. Int J Adv Manuf Technol 31(7–8):629–637

Beake BD, Fox-Rabinovich GS, Veldhuis SC, Goodes SR (2009) Coating optimisation for high speed machining with advanced nanomechanical test methods. Surf Coat Technol 203(13):1919–1925

Bouzakis KD, Michailidis N, Skordaris G, Bouzakis E, Biermann D, M’Saoubi R (2012) Cutting with coated tools: coating technologies, characterization methods and performance optimization. CIRP Ann Manuf Technol 61(2):703–723

Wang SQ, Chen L, Yang B, Chang KK, Du Y, Li J, Gang T (2010) Effect of Si addition on microstructure and mechanical properties of Ti–Al–N coating. Int J Refract Metal Hard Mater 28(5):593–596

Lugscheider E, Geiler HD, Lake M, Zimmermann H (1996) Investigation of thermophysical properties of AIP coated cutting tools for dry machining. Surf Coat Technol 86:803–808

Akbar F, Mativenga P T, Sheikh M A (2007) An investigation of the tool-chip interface temperature and heat partition in high-speed machining of aisi/sae 4140 steel with tin-coated tool. Proceed 35th Int MATADOR Conf. Springer London, pp 215–218.

Loewen EF, Shaw MC (1954) On the analysis of cutting tool temperatures. Trans ASME 71:217–231

Reznikov AN, Reznikov AN (1981) Thermophysical aspects of metal cutting processes. Mashinostroenie, Moscow, p 212

Shaw MC (2005) Metal cutting principles. Oxford university press, New York

Fujii H (1999) Energy partition in conventional surface grinding. J Manuf Sci Eng 121:393

Grzesik W, Nieslony P (2004) Physics based modelling of interface temperatures in machining with multilayer coated tools at moderate cutting speeds. Int J Mach Tool Manuf 44(9):889–901

Grzesik W, Nieslony P (2004) Prediction of friction and heat flow in machining incorporating thermophysical properties of the coating–chip interface. Wear 256(1):108–117

Abukhshim NA, Mativenga PT, Sheikh MA (2005) Investigation of heat partition in high speed turning of high strength alloy steel. Int J Mach Tool Manuf 45(15):1687–1695

Ghani MU, Abukhshim NA, Sheikh MA (2008) An investigation of heat partition and tool wear in hard turning of H13 tool steel with CBN cutting tools. Int J Adv Manuf Technol 39(9–10):874–888

Rech J, Kusiak A, Battaglia JL (2004) Tribological and thermal functions of cutting tool coatings. Surf Coat Technol 186(3):364–371

Rech J, Arrazola PJ, Claudin C, Courbon C, Pusavec F, Kopac J (2013) Characterisation of friction and heat partition coefficients at the tool-work material interface in cutting. CIRP Ann Manuf Technol 62(1):79–82

Akbar F, Mativenga PT, Sheikh MA (2009) On the heat partition properties of (Ti, Al) N compared with TiN coating in high-speed machining. Proc Inst Mech Eng Part B J Eng Manuf 223(4):363–375

Akbar F, Mativenga PT, Sheikh MA (2008) An evaluation of heat partition in the high-speed turning of AISI/SAE 4140 steel with uncoated and TiN-coated tools. Proc Inst Mech Eng Part B J Eng Manuf 222(7):759–771

Puls H, Klocke F, Veselovac D (2016) FEM-based prediction of heat partition in dry metal cutting of AISI 1045. Int J Adv Manuf Technol 86(1–4):737–745

Zemzemi F, Rech J, Salem WB, Dogui A, Kapsa P (2014) Identification of friction and heat partition model at the tool-chip-workpiece interfaces in dry cutting of an Inconel 718 alloy with CBN and coated carbide tools. Adv Manuf Sci Technol 38(1):5–12

Courbon C, Mabrouki T, Rech J, Mazuye D, D’Eramo E (2013) On the existence of a thermal contact resistance at the tool-chip interface in dry cutting of AISI 1045: formation mechanisms and influence on the cutting process. Appl Therm Eng 50(1):1311–1325

Lee EH, Shaffer BW (1952) The theory of plasticity applied to a problem of machining. Trans ASME J Appl Mech 18:405–413

Grzesik W, Bartoszuk M, Nieslony P (2005) Finite element modelling of temperature distribution in the cutting zone in turning processes with differently coated tools. J Mater Process Technol 164:1204–1211

Grzesik W, Niesłony P (2008) FEM–based thermal modelling of the cutting process using power law-temperature dependent concept. Arch Mater Sci Eng 29(2):105–108

Ucun İ, Aslantas K (2011) Numerical simulation of orthogonal machining process using multilayer and single-layer coated tools. Int J Adv Manuf Technol 54(9–12):899–910

Du F, Lovell MR, Wu TW (2001) Boundary element method analysis of temperature fields in coated cutting tools. Int J Solid Struct 38(26):4557–4570

Ng EG, Aspinwall DK, Brazil D, Monaghan J (1999) Modelling of temperature and forces when orthogonally machining hardened steel. Int J Mach Tool Manuf 39(6):885–903

Chunhua R (2013) Comparative study on cutting performance of TiN, TiAIN coated tool. Dissertation, Southwestern University

Chen RY (2002) Metal cutting principles. China Machine Press, Beijing, pp 57–59

Fahad M (2012) A heat partition investigation of multilayer coated carbide tools for high speed machining through experimental studies and finite element modelling. Dissertation, University of Manchester

Choi JB, Cho K, Lee MH, Kim KH (2004) Effects of Si content and free Si on oxidation behavior of Ti–Si–N coating layers. Thin Solid Film 447:365–370

Long Y, Zeng J, Shanghua W (2014) Cutting performance and wear mechanism of Ti–Al–N/Al–Cr–O coated silicon nitride ceramic cutting inserts. Ceram Int 40(7):9615–9620

Baowan P, Saikaew C, Wisitsoraat A (2017) Influence of helix angle on tool performances of TiAlN- and DLC-coated carbide end mills for dry side milling of stainless steel. Int J Adv Manuf Technol 90(9–12):3085–3097

Pfeiler M, Zechner J, Penoy M, Michotte C, Mitterer C, Kathrein M (2009) Improved oxidation resistance of TiAlN coatings by doping with Si or B. Surf Coat Technol 203(20):3104–3110

Chen L, Du Y, Wang SQ, Wang AJ, Xu HH (2009) Mechanical properties and microstructural evolution of TiN coatings alloyed with Al and Si. Mater Sci Eng A 502(1):139–143

Jiang F, Yan L, Rong Y (2013) Orthogonal cutting of hardened AISI D2 steel with TiAlN-coated inserts—simulations and experiments. Int J Adv Manuf Technol 64(9–12):1555–1563

Funding

This work is supported by the National Natural Science Foundation of China (No. 51405254), and Special Grade of the financial support from the China Postdoctoral Science Foundation (No. 2015T80712) and Shandong province postdoctoral innovation project special funds (No. 2014M561919).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, D., Jingjie, Z. & Liguo, W. Heat partition and rake face temperature in the machining of H13 steel with coated cutting tools. Int J Adv Manuf Technol 94, 3691–3702 (2018). https://doi.org/10.1007/s00170-017-1122-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-1122-3