Abstract

This paper proposes an efficient methodology for concurrent multi-scale design optimization of composite frames considering specific design constraints to obtain the minimum structure cost when the fundamental frequency is considered as a constraint. To overcome the challenge posed by the strongly singular optimum and the weakness of the conventional polynomial material interpolation (PLMP) scheme, a new area/moment of inertia–density interpolation scheme, which is labeled as adapted PLMP (APLMP) is proposed. The APLMP scheme and discrete material optimization approach are employed to optimize the macroscopic topology of a frame structure and microscopic composite material selection concurrently. The corresponding optimization formulation and solution procedures are also developed and validated through numerical examples. Numerical examples show that the proposed APLMP scheme can effectively solve the singular optimum problem in the multi-scale design optimization of composite frames with fundamental frequency constraints. The proposed multi-scale optimization model for obtaining the minimum cost of structures with a fundamental frequency constraint is expected to provide a new choice for the design of composite frames in engineering applications.

Similar content being viewed by others

References

Andreasen CS, Sigmund O (2012) Multiscale modeling and topology optimization of poroelastic actuators. Smart Mater Struct 21(6):065005

Bailie JA, Ley RP, Pasricha A (1997) A summary and review of composite laminate design guidelines. National Aeronautics and Space Administration, Final Report Task 22

Bendsoe MP, Sigmund O (2013) Topology optimization-theory, methods and applications. Springer Science & Business Media, New York

Bruggi M (2008) On an alternative approach to stress constraints relaxation in topology optimization. Struct Multidiscip Optim 36(2):125–141

Bruyneel M (2011) SFP-a new parameterization based on shape functions for optimal material selection: application to conventional composite plies. Struct Multidiscip Optim 43(1):17–27

Cheng GD, Guo X (1997) ε-relaxed approach in structural topology optimization. Struct Optim 13(4):258–266

Cheng GD, Olhoff N (1993) Rigid body motion test against error in semi-analytical sensitivity analysis. Comput Struct 46(3):515–527

Coelho PG, Fernandes PR, Guedes JM, Rodrigues HC (2008) A hierarchical model for concurrent material and topology optimisation of three-dimensional structures. Struct Multidiscip Optim 35(2):107–115

Coelho PG, Guedes JM, Rodrigues HC (2015) Multiscale topology optimization of bi-material laminated composite structures. Compos Struct 132:495–505

Costa G, Montemurro M, Pailhès J (2018) A 2D topology optimisation algorithm in NURBS framework with geometric constraints. Int J Mech Mater Des 14(4):669–696

Costa G, Montemurro M, Pailhès J (2019a) NURBS hyper-surfaces for 3D topology optimization problems. Mech Adv Mater Struct 28(7):665–684

Costa G, Montemurro M, Pailhès J (2019b) Minimum length scale control in a NURBS-based SIMP method. Comput Methods Appl Mech Eng 354:963–989

Deng JD, Yan J, Cheng GD (2013) Multi-objective concurrent topology optimization of thermoelastic structures composed of homogeneous porous material. Struct Multidiscip Optim 47(4):583–597

Du JB, Olhoff N (2007) Topological design of freely vibrating continuum structures for maximum values of simple and multiple eigenfrequencies and frequency gaps. Struct Multidiscip Optim 34(2):91–110

Duan ZY, Yan J, Zhao GZ (2015) Integrated optimization of the material and structure of composites based on the Heaviside penalization of discrete material model. Struct Multidiscip Optim 51(3):721–732

Duan ZY, Yan J, Lee IJ, Lund E, Wang JY (2019a) A two-step optimization scheme based on equivalent stiffness parameters for forcing convexity of fiber winding angle in composite frames. Struct Multidiscip Optim 59(6):2111–2129

Duan ZY, Yan J, Lee IJ, Lund E, Wang JY (2019b) Discrete material selection and structural topology optimization of composite frames for maximum fundamental frequency with manufacturing constraints. Struct Multidiscip Optim 60(5):1741–1758

Ferreira RT, Rodrigues HC, Guedes JM, Hernandes JA (2013) Hierarchical optimization of laminated fiber reinforced composites. Compos Struct 107:246–259

Guo X, Cheng GD (2000) An extrapolation approach for the solution of singular optima. Struct Multidiscip Optim 19(4):255–262

Gao T, Zhang WH, Duysinx P (2013) Simultaneous design of structural layout and discrete fiber orientation using bi-value coding parameterization and volume constraint. Struct Multidiscip Optim 48(6):1075–1088

Gao J, Luo Z, Li H, Gao L (2019) Topology optimization for multiscale design of porous composites with multi-domain microstructures. Comput Methods Appl Mech Eng 344:451–476

Giulio G, Montemurro M (2020) Eigen-frequencies and harmonic responses in topology optimisation: a CAD-compatible algorithm. Eng Struct 214:110602

Huang X, Zhou SW, Xie YM, Li Q (2013) Topology optimization of microstructures of cellular materials and composites for macrostructures. Comput Mater Sci 67:397–407

Hvejsel CF, Lund E (2011) Material interpolation schemes for unified topology and multi-material optimization. Struct Multidiscip Optim 43(6):811–825

Izzi MI, Montemurro M, Catapano A, Pailhès J (2020) A multi-scale two-level optimisation strategy integrating a global/local modelling approach for composite structures. Compos Struct 237:111908

Jones RM (2014) Mechanics of composite materials. CRC Press, Boca Raton

Liu L, Yan J, Cheng GD (2008) Optimum structure with homogeneous optimum truss-like material. Comput Struct 86(13):1417–1425

Lund E (1994) Finite element based design sensitivity analysis and optimization. Institute of Mechanical Engineering, Aalborg University, Denmark, p 107

Ma XT, Tian K, Li H, Zhou Y, Hao P, Wang B (2020) Concurrent multi-scale optimization of hybrid composite plates and shells for vibration. Compos Struct 233:111635

Montemurro M, Pagani A, Fiordilino GA, Pailhès J, Carrera E (2018) A general multi-scale two-level optimisation strategy for designing composite stiffened panels. Compos Struct 201:968–979

Mallick P.K., Fiber-reinforced composites: materials, manufacturing, and design. CRC press, 2017.

Martins LAL, Bastian FL, Netto TA (2014) Reviewing some design issues for filament wound composite tubes. Mater Des 55:242–249

Ni CH, Yan J, Cheng GD, Guo X (2014) Integrated size and topology optimization of skeletal structures with exact frequency constraints. Struct Multidiscip Optim 50(1):113–128

Nikbakt S, Kamarian S, Shakeri M (2018) A review on optimization of composite structures Part I: laminated composites. Compos Struct 195:158–185

Niu B, Yan J, Cheng GD (2009) Optimum structure with homogeneous optimum cellular material for maximum fundamental frequency. Struct Multidiscip Optim 39(2):115–132

Ohsaki M, Fujisawa K, Katoh N, Kanno Y (1999) Semi-definite programming for topology optimization of trusses under multiple eigenvalue constraints. Comput Methods Appl Mech Eng 180(1–2):203–217

Panettieri E, Montemurro M, Catapano A (2019) Blending constraints for composite laminates in polar parameters space. Compos B Eng 168:448–457

Rodrigues H, Guedes JM, Bendsoe MP (2002) Hierarchical optimization of material and structure. Struct Multidiscip Optim 24(1):1–10

Scardaoni MP, Montemurro M (2020) A general global-local modelling framework for the deterministic optimisation of composite structures. Struct Multidiscip Optim 62:1927–1949

Scardaoni MP, Montemurro M, Panettieri E, Catapano A (2021) New blending constraints and a stack-recovery strategy for the multi-scale design of composite laminates. Struct Multidiscip Optim 63(2):741–766

Sørensen SN, Sørensen R, Lund E (2014) DMTO–a method for discrete material and thickness optimization of laminated composite structures. Struct Multidiscip Optim 50(1):25–47

Stegmann J, Lund E (2005) Discrete material optimization of general composite shell structures. Int J Numer Meth Eng 62(14):2009–2027

Svanberg K (2007) MMA and GCMMA, versions September 2007. Optim Syst Theory 104.

Tao W, Liu Z, Zhu P, Zhu C, Chen W (2017) Multi-scale design of three dimensional woven composite automobile fender using modified particle swarm optimization algorithm. Compos Struct 181:73–83

Wittrick WH (1962) Rates of change of eigenvalues, with reference to buckling and vibration problems. Aeronaut J 66(621):590–591

Wu C, Gao Y, Fang J, Lund E, Li Q (2019) Simultaneous discrete topology optimization of ply orientation and thickness for carbon fiber reinforced plastic-laminated structures. J Mech Des 141(4):044501

Xia L, Breitkopf P (2014) Concurrent topology optimization design of material and structure within FE2 nonlinear multiscale analysis framework. Comput Methods Appl Mech Eng 278:524–542

Xu B, Jiang J, Tong W, Wu K (2003) Topology group concept for truss topology optimization with frequency constraints. J Sound Vib 261(5):911–925

Xu B, Xie YM (2015) Concurrent design of composite macrostructure and cellular microstructure under random excitations. Compos Struct 123:65–77

Xu YJ, Zhu J, Wu Z, Cao Y, Zhao Y, Zhang W (2018) A review on the design of laminated composite structures: constant and variable stiffness design and topology optimization. Adv Compos Hybrid Mater 1(3):460–477

Xuan L, Du JB (2019) Concurrent multi-scale and multi-material topological optimization of vibro-acoustic structures. Comput Methods Appl Mech Eng 349:117–148

Yamada S, Kanno Y (2016) Relaxation approach to topology optimization of frame structure under frequency constraint. Struct Multidiscip Optim 53(4):731–744

Yan J, Cheng GD, Liu L (2008) A uniform optimum material based model for concurrent optimization of thermoelastic structures and materials. Int J Simul Multi Design Optim 2(4):259–266

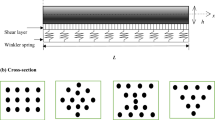

Yan J, Duan ZY, Lund E, Wang J (2017) Concurrent multi-scale design optimization of composite frames with manufacturing constraints. Struct Multidiscip Optim 56(3):519–533

Yan J, Guo X, Cheng GD (2016) Multi-scale concurrent material and structural design under mechanical and thermal loads. Comput Mech 57(3):437–446

Yan J, Sui Q, Fan Z, Duan ZY, Yu T (2020) Clustering-based multiscale topology optimization of thermo-elastic lattice structures. Comput Mech 66(4):979–1002

Zuo ZH, Huang X, Rong JH, Xie YM (2013) Multi-scale design of composite materials and structures for maximum natural frequencies. Mater Des 51:1023–1034

Acknowledgements

Financial supports for this research were provided by the National Natural Science Foundation of China (Nos. 12002278, 11672057, U1906233), the Key R&D Program of Shandong Province (2019JZZY010801), the Fundamental Research Funds for the Central Universities (NWPU-G2020KY05308), and the 111 project (B14013). These supports are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Responsible Editor: Emilio Carlos Nelli Silva

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix Layer-wise constant shear beam theory

Appendix Layer-wise constant shear beam theory

The transformed stress–strain relation of an orthotropic single lamina under the assumption of plane stress in the x–y plane without the transverse normal stress component in the structure coordinates [\(x\) \(y\) \(z\)] (see Fig. 21) can be written as

where \({\bar{Q} }_{pq}\) (\(p,q\in\) 1, 2, 4, 5, 6) is the transformed reduced stiffness. The reduced stiffness \({Q}_{pq}\) can be expressed as follows:

The invariant parameters \({U}_{1}-{U}_{6}\) are defined to efficiently calculate \({\bar{Q} }_{pq}\) as.

Then, \({\bar{Q} }_{pq}\) can be expressed as.

where \({\theta }_{i,j}\) is the fiber winding angle for layer \(j\) of tube \(i\). The layers are numbered with the inner layer as the first layer. The schematic of the fiber winding angle definition is shown in Fig. 21 for a single layer, where \(+{\theta }_{i,j}\) denotes the positive fiber winding angle; \(x\), \(y\), and \(z\) are the beam structure coordinates; and 1, 2, and 3 are the principal material coordinates.

Assuming that the laminated beam is a one-dimensional component, the coordinate \(y\) is the circumferential direction along a circular cross-section beam; thus, \({\sigma }_{y}={\sigma }_{yz}={\sigma }_{xy}=0\) (Jones 2014) is applied in Eq. (27), which yields

where the equivalent elastic modulus along the x-direction and shear modulus in the x–z plane of the j-th layer of the i-th tube, \({{E}_{x}}^{i,j}\) and \({{G}_{xz}}^{i,j},\) are given respectively by

and

respectively. With the derivation above, \({{E}_{x}}^{i,j}\) and \({{G}_{xz}}^{i,j}\) are expressed as a function of the fiber winding angles with fixed orthotropic material properties.

Rights and permissions

About this article

Cite this article

Duan, Z., Wang, J., Xu, B. et al. A new method for concurrent multi-scale design optimization of fiber-reinforced composite frames with fundamental frequency constraints. Struct Multidisc Optim 64, 3773–3795 (2021). https://doi.org/10.1007/s00158-021-03054-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-021-03054-3