Abstract

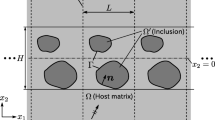

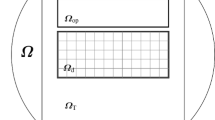

Hyperbolic elastic metamaterials developed for sub-wavelength resolution allow wave propagation in the radial direction but prohibit wave propagation in the circumferential direction. Recently, a two-dimensional elastic metamaterial truly exhibiting the hyperbolic behavior has been realized and also experimented but there is a practically important design issue that its operating frequency range should be widened. Motivated by this need, the present investigation aims to set up a topology optimization formulation to maximize the operating frequency range. Because different wave physics are involved along the circumferential and radial directions, the topology optimization requires the extraction of the key physical phenomena along the two different directions. In doing so, the wave physics occurring in the hyperbolic elastic metamaterial is analyzed by using equivalent discrete models and the findings from the analysis are used to set up a topology optimization problem. The topology optimization that maximizes the operating frequency range of the hyperbolic elastic metamaterial is newly formulated by using the finite element method. After the metamaterial configuration maximizing the frequency range is found, the mechanics hidden in the optimized configuration is explained in some details by using analytic mass-spring model.

Similar content being viewed by others

References

Ao X, Chan CT (2008) Far-field image magnification for acoustic waves using anisotropic acoustic metamaterials. Phys Rev E 77:025601

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71:197–224

Bendsøe MP, Sigmund O (2003) Topology optimization, Springer

Brillouin L (1946) Wave propagation in periodic structures. Dover, New York

Chiang TY, Wu LY, Tsai CN, Chen LW (2011) A multilayered acoustic hyperlens with acoustic metamaterials. Appl Phys A 103:355–359

Choi KK, Kim NH (2005) Structural sensitivity analysis and optimization. Springer, New York

Diaz AR, Sigmund O (2010) A topology optimization method for design of negative permeability metamaterials. Struct Multidiscip Optim 41:163–177

Dühring MB, Sigmund O, Feurer T (2010) Design of photonic bandgap fibers by topology optimization. Opt Soc Am B 27:51–58

Haber RB, Jog CS, Bendsoe MP (1996) A new approach to variable-topology shape design using a constraint on perimeter. Struct Opt 11:1–12

Huang HH, Sun CT, Huang GL (2009) On the negative effective mass density in acoustic metamaterials. Int J Eng Sci 47:610–617

Huang Y, Liu S, Zhao J (2013) Optimal design of two-dimensional band-gap materials for uni-directional wave propagation. Struct Multidiscip Optim 48:487–499

Hussein MI (2004) Dynamics of banded materials and structures: analysis, design and computation in multiple scales. Dissertation, University of Michigan

Jacob Z, Alekseyev LV, Narimanov EE (2006) Optical hyperlens: Far-field imaging beyond the diffraction limit. Opt Exp 14:8247–8256

Jang GW, Jeong JH, Kim YY, Sheen DW, Park CJ, Kim MN (2003) Checkerboard-free topology optimization using non-conforming finite elements. Int J Numer Methods Eng 57:1717–1735

Kildishev AV, Narimanov EE (2007) Impedance-matched hyperlens. Opt Lett 32:3432–3434

Kim SI, Kim YY (2014) Topology optimization of planar linkage mechanisms. Int J Numer Methods Eng 98:265–286

Kushwaha MS, Halevi P, Dobrzynski L, Djafari-Rouhani B (1993) Acoustic band structure of periodic elastic composites. Phys Rev Lett 71:2022–2025

Langlet P, Hladky-Hennion AC, Decarpigny JN (1995) Analysis of the propagation of plane acoustic waves in passive periodic materials using the finite element method. J Acoust Soc Am 98:2792–2800

Lee J, Kikuchi N (2010) Structural topology optimization of electrical machinery to maximize stiffness with body force distribution. IEEE Trans Magn 46:3790–3794

Lee H, Liu Z, Xiong Y, Sun C, Zhang X (2007) Development of optical hyperlens for imaging below the diffraction limit. Opt Exp 15:15886–15891

Lee HJ, Kim HW, Kim YY (2011) Far-field subwavelength imaging for ultrasonic elastic waves in a plate using an elastic hyperlens. Appl Phys Lett 98:241912

Li J, Fok L, Yin X, Bartal G, Zhang X (2009) Experimental demonstration of an acoustic magnifying hyperlens. Nat Mater 8:931–934

Liu Z, Lee H, Xiong Y, Sun C, Zhang X (2010) Far-field optical hyperlens magnifying Sub-diffraction-limited objects. Science 315:1686

Lu D, Liu Z (2012) Hyperlenses and metalenses for far-field super-resolution imaging. Nat Commun 3:1205. doi:10.1038/ncomms2176

Lu L, Yamamoto T, Otomori M, Yamada T, Izui K, Nishiwaki S (2013) Topology optimization of an acoustic metamaterial with negative bulk modulus using local resonance. Finite Elem Anal Des 72:1–12

Oh JH (2014) Sub-wavelength resolution in ultrasonic waves by hyperbolic metamaterials. Dissertation, Seoul National University

Oh JH, Seung HM, Kim YY (2014) A truly hyperbolic elastic metamaterial lens. Appl Phys Lett 104:073503

Otomori M, Yamada T, Izui K, Nishiwaki S, Andkjær J (2012) A topology optimization method based on the level set method for the design of negative permeability dielectric metamaterials. Comput Methods Appl Mech Eng 237–240:192–211

Rho J et al (2010) Spherical hyperlens for two-dimensional sub-diffractional imaging at visible frequencies. Nat Commun 1:143. doi:10.1038/ncomms1148

Rupp CJ, Evgrafov A, Maute K, Dunn ML (2007) Design of phononic materials/structures for surface wave devices using topology optimization. Struct Multidiscip Optim 34:111–121

Salandrino A, Engheta N (2006) Far-field subdiffraction optical microscopy using metamaterial crystals: Theory and simulations. Phys Rev B 74:075103

Sigalas M, Economou EN (1993) Band structure of elastic waves in two dimesional systems. Solid State Commun 86:141–143

Sigmund O, Jensen JS (2003) Systematic design of phononic band-gap materials and structures by topology optimization. Philos Trans R Soc Lond A 361:1001–1019

Svanberg K (1987) The method of moving asymptotes - a new method for structural optimization. Int J Numer Methods Eng 24:359–373

Wang W et al (2008) Far-field imaging device: planar hyperlens with magnification using multi-layer metamaterial. Opt Express 16:21142–21148

Xiong Y, Liu Z, Zhang X (2009) A simple design of flat hyperlens for lithography and imaging with half-pitch resolution down to 20 nm. Appl Phys Lett 94:203108

Acknowledgments

This work was supported by the National Research Foundation of Korea (NRF) grant (No: 2015021967) funded by the Korean Ministry of Education, Science and Technology (MEST), Basic Science Research Program through NRF funded by the Korean Ministry of Education (No: 2014048162), contracted through IAMD (Institute of Advanced Machines and Design) at Seoul National University and the Global Frontier R&D Program on Center for Wave Energy Control based on Metamaterials funded by the National Research Foundation under the Ministry of Science, ICT & Future Planning, Korea (No: CAMM-2014M3A6B3063711).

Author information

Authors and Affiliations

Corresponding author

Appendix. Validation of the mass-spring system based approaches

Appendix. Validation of the mass-spring system based approaches

In Appendix, the wave dispersion relations in (3) and (17), which are based on the mass-spring systems shown in Figs. 3 and 4, will be validated. To this end, the equivalent mass and spring coefficients of the unit cell are first calculated analytically. Then the dispersion curves based on the mass-spring model are compared with those of the finite element analysis incorporating a full continuum model of the unit cell.

Since the operating frequencies are relatively low for which the unit cell size is much smaller than the wavelength, the equivalent mass coefficients (m 1, m 2, m 3 and m 4) can be calculated directly from the density and volume of each segment shown in Fig. 13a. Considering the wave motion in Segment S 1 shown in Fig. 13b, the spring coefficients a 1 and a 3 can be evaluated as

On the other hand, due to the complicated configuration of Segment S 2, the spring coefficients a 2 and a 4 are calculated from the energy method. From the total energy of Segment S 2, the spring coefficient a 2 is calculated as (Oh et al. 2014)

where \( {I}_{{\mathrm{S}}_2} \) is the moment of inertia of Segment S 2 defined as \( {I}_{{\mathrm{S}}_2}={l}_{{\mathrm{S}}_2}{t}_{{\mathrm{S}}_2}^3/12 \). One can show that A and B can be calculated from the boundary condition as

In the same manner, the spring coefficient a 4 is calculated as (Oh 2014)

where κ is the shear-correction factor (κ = 5/6) and C and D can be calculated from the following equation;

For more details about the calculation of mass and spring coefficients, see Oh (2014) and Oh et al. (2014).

By using the equivalent mass and spring coefficients, the wave dispersion curves are calculated from (3, 17) and from the finite element analysis method, as in Figs. 14 and 15. Here, the metamaterials having the width of 9.8, 14.4 and 19.2 mm are considered. Good agreements between two dispersion curves can be observed in the Figs. 14 and 15, which demonstrate a good correlation in mechanics between the mass-spring systems and actual unit cell structures. Also, considering the definition of the shear resonance frequency \( {\omega}_{shear}=\sqrt{2{a}_4/{m}_4} \), it can be seen that the internal resonance frequency ω shear can be calculated by using Segment S2 only, as employed in the present multi-model based analysis.

Rights and permissions

About this article

Cite this article

Oh, J.H., Ahn, Y.K. & Kim, Y.Y. Maximization of operating frequency ranges of hyperbolic elastic metamaterials by topology optimization. Struct Multidisc Optim 52, 1023–1040 (2015). https://doi.org/10.1007/s00158-015-1288-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00158-015-1288-y