Abstract

The overall aim of this study was to investigate the durability of acetylated beech (Fagus sylvatica L.) laminated veneer lumber (LVL) against wood-destroying basidiomycetes. The secondary objective was to test whether the specimen size affects the mass loss and durability assessment of wood-material under test. The durability test was based on the pre-standard prEN 113-3. Six materials (acetylated beech LVL, untreated beech LVL, beech solid wood, pine sapwood (Pinus sylvestris L.), larch (Larix decidua Mill.) 3-layer slab, larch solid wood) were tested using three specimen geometry designs (50 × 25 × 15 mm3 as well as 50 × 50 × 19 mm3 with and without sealed edges) against Coniophora puteana, Rhodonia placenta, Gloeophyllum trabeum, Trametes versicolor, and Pleurotus ostreatus. The durability assessment was made using the arithmetic mean and median percentage mass loss (ML), the relative ML (x-values), and the decay susceptibility index (DSI). It was found that mass loss was affected by the test fungus, the material, and the specimen size and design, with the latter being the most essential factor in this study. In addition, the assessment parameter had a significant effect on the durability classification. Furthermore, small differences in ML resulted in different durability classes (DC) in some cases, whereas large differences in ML did not. However, acetylated beech LVL was always considerably durable (DC 1) against all tested fungi independent of the specimen design and durability assessment method.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Acetylation of wood with acetic anhydride has attracted much attention in recent years by improving the durability and dimensional stability of wood. During acetylation of wood, hydroxyl groups react with acetic anhydride to form covalent bonds and acetic acid as by-product (Hill 2006). Acetylation is one of the few chemical wood modification methods that have established on the European market. Thereby, pine (Pinus radiata D. Don) was the primary wood species (Bongers et al. 2013). Yet other wood species are also appealing for this process.

For instance, European beech (Fagus sylvatica L.) is one of the most important hardwood species in Europe and particularly prevalent in Germany and France. The mechanical properties of beech wood are significantly higher compared to other coniferous timbers such as Norway spruce (Picea abies Karst.), which are commonly used in the building trade (Wagenführ 2007), and may allow new designs in timber construction. However, the durability of beech against wood destroying fungi and its dimensional stability in contact with moisture are severely limited (Bicke 2019; EN 350 2016). Moreover, the false heartwood of beech is hard to impregnate (EN 350 2016). To overcome these limitations, acetylated veneer-based products such as laminated veneer lumber (LVL) and plywood are currently under development (Slabohm et al. 2022a; Wang et al. 2021, 2022).

In general, veneers are first acetylated and then bonded to veneer-based products. The bonding of acetylated wood has been the subject of extensive studies (Bongers et al. 2016; Frihart et al. 2017; Olaniran et al. 2021; Slabohm et al. 2022a, b; Slabohm and Militz 2022a; Treu et al. 2020; Vick and Rowell 1990). Additionally, numerous studies on materials made from acetylated veneer were conducted. For example, it was found that the mechanical properties of birch plywood are barely affected by acetylation (Wang et al. 2022). Another study discovered that acetylation does not prevent beech plywood from fire (Mohebby et al. 2007). Reduced wood-moisture interaction and improved dimensional stability were found for acetylated beech LVL compared to untreated references after submersion in water, but especially after a boiling-drying-boiling cycle (Slabohm and Militz 2022a). Following long-term outdoor exposure, acetylation does not significantly enhance the photostability of wood (Chao et al. 2020; Dunningham et al. 1992; Evans et al. 2000).

However, during the manufacturing of plywood and LVL, the material is exposed to temperatures of up to 150 °C, to cure the adhesive, and it is still unknown whether the bonded acetyl groups are cleaved-off (de-acetylate) in the presence of adhesives, high temperatures, and pressure. As a result of de-acetylation, the biological durability of the material could be reduced.

Imamura and Nishimoto (1986) tested the durability of acetylated LVL made of several softwood species against subterranean termites. Even after hot-bonding at 110 °C, they discovered improved durability. However, their research was limited to the durability against termite attack with a mode of action that can be significantly different from that against decay fungi. In another research, acetylated veneer-faced low-density particleboards were produced at temperatures of 160 °C for 5 min and tested in an 8-week soil block test (Rowell et al. 1989). The boards were resistant to Tyromyces palustris and Trametes versicolor. Nevertheless, acetylated veneer-faced low-density particleboards and acetylated beech LVL differ in a number of ways (for instance, resin type, pressing time, wood species, and the acetylation process). Another indicator that deacetylation did not occur is that the dimensional stability remained improved after hot-bonding (Slabohm and Militz 2022a, b) and was similar to that of acetylated solid wood (Rowell 2014). However, further research on the durability of acetylated veneer-based products is needed.

The durability of wood against white and brown rot fungi is often tested in laboratories using basidiomycete monocultures under most favorable conditions for fungal decay. Thereby, the oven-dry mass of sterilized specimens is determined before and after incubation with selected test fungi. However, worldwide durability standards vary with respect to specimen size and shape as well as incubation periods.

In Europe, EN 350 (2016) is the overarching standard that defines durability classes (DC) and refers to various test standards, such as agar plate tests according to EN 113-2 (2021). The latter is the preferred test method for determining the durability of solid wood. Test specimens of 50 (long.) × 25 × 15 mm3 are incubated for 16 weeks to selected brown and white rot fungi. The mass loss (ML) caused by fungal decay is thereafter used to assign DCs. In contrast, the standard ENV 12038 (2002) describes a laboratory method for testing the durability of wood composites using specimens of 50 × 50 × thickness (mm3). While the specimens are significantly larger compared to those required by EN 113-2 (2021), the incubation time is 16 weeks in both cases. Instead of DCs, ENV 12038 (2002) suggests to determine the decay susceptibility index (DSI). Low values indicate high resistance to fungal degradation, while high values indicate low resistance. For instance, DSI = 100% means that the sample was completely susceptible to fungal attack (Amusant et al. 2009).

In 2021, ENV 12038 (2002) was replaced by EN 113-3 (2021). The test procedure including specimen size and incubation time has been inherited, but the new standard allows for durability classification of wood composites. The latter is based on the median ML in coincidence with EN 113-2 (2021). It might be questioned whether the use of specimens of approximately the double volume will show the same ML and thus the same DC. Previous studies with solid larch heartwood (Brischke et al. 2021) showed that the wood specimens’ format (shape and size) has a significant impact on both, the ML and the durability assessment. In addition, the effect of the large cut side edges of the specimens on ML during incubation has been debated. LVL, plywood and further composites are usually applied as large-sized boards with relatively small percentage of side edges, which ideally are sealed in outdoor applications. To mimic the real-life proportions of panel composites, the edges of small clear specimens might be sealed with a material that is impermeable for water and fungal hyphae.

The superior aim of this study was to determine the biological durability of acetylated beech LVL. The secondary objective was to test whether the specimen design possesses impacts on the ML of the specimens and the resulting durability assessment. Therefore, in total six different wood-based materials underwent comparative incubation experiments using different specimen designs.

2 Materials and methods

2.1 Materials

LVL made from acetylated beech was the material of interest and untreated beech LVL was used as a reference. Beech veneers (2200 × 1000 mm2) with and without sections of discolored red-heart were used for acetylation at an industrial production plant of Accsys Technologies S.A. (Arnhem, The Netherlands), while half of the veneers remained untreated. The veneers were acetylated to a weight percent gain (WPG) of about 24.4% (SD = 0.5%) (Slabohm et al. 2022b). Eight-layered LVL boards were bonded in a hydraulic press (HP-S 1200, Gottfried Joos Maschinenfabrik GmbH & Co. KG) at 150 °C for 30 min at a pressure of 1 N/mm2. Prior to that, a hand roller was used to apply 180 g/m2 of a 2-component phenol–resorcinol–formaldehyde (PRF) resin one-sided on seven veneers. The liquid hardener Prefere 5839 (Dynea AS) was mixed with Prefere 4040 resin (Dynea AS) at a weight ratio of 20:100 to create the PRF resin. After cooling, the surfaces were sanded (P100).

In addition, specimens were made from solid wood and 3-layer slabs, both made from European larch (Larix decidua Mill.) and used as additional reference materials and for benchmarking. A commercial larch 3-layer slab with a thickness of 19 mm was used. The surfaces were also sanded (P100). European beech and Scots pine sapwood (Pinus sylvestris L.) were used for manufacturing virulence control specimens.

2.2 Specimen preparation

Specimens of three different designs were prepared (Fig. 1). All specimens were oven-dried at 103 ± 2 °C, weighed to the nearest 0.01 g, leached according to EN 84 (2020), oven-dried, and weighed again. The mass loss during leaching (ΔmL) was calculated using the following Eq. (1):

where ΔmL = mass loss during leaching [%], m0 = oven-dry mass before leaching [g], m0L = oven-dry mass after leaching [g].

Overview specimen designs. A Specimen according to EN 113-2 (2021), volume: 18.75 cm3; total surface: 47.5 cm2, surface/volume ratio: 2.53 cm−1; B specimen according to EN 113-3 (2021), volume: 47.5 cm3, total surface: 88.0 cm2, surface/volume ratio: 1.85 cm−1; C specimen according to EN 113-3 (2021), volume: 47.5 cm3, total surface: 50.0 cm2, surface/volume ratio: 1.05 cm−1. Anatomical directions for veneer-based products: l longitudinal, r radial, t tangential; the annual rings on solid wood specimens are rotated by 45°

After leaching, specimens were conditioned at 20 °C/65% RH. Half of the specimens of 50 × 50 × 19 (long. × rad. × tang.) mm3 were sealed around all edges with polyurethane (Sikaflex® 221i, Sika Austria GmbH, Austria). The mass of the specimens was taken before and after the sealing was applied. The mass of the sealant was calculated using the following Eq. (2).

where msealant = mass of the sealant [g], munsealed = specimen mass before sealing [g], msealed = specimen mass after sealing [g].

2.3 Durability tests with basidiomycete monocultures

In total, 1080 specimens were exposed to basidiomycete monocultures. Twelve replicate specimens were used per combination of fungus, specimen design, and test material. All specimens were kept in a culture vessel (polyethylene jars) containing malt agar (4%). In each culture vessel, one specimen of 50 × 50 × 20 mm2 or two specimens of 50 × 25 × 15 mm2 were placed on stainless-steel washers. Prior to incubation, a 20-min pressureless steam sterilization was performed, followed by 24 h of cooling and another 10 min of steaming. A possible deacetylation could also occur during steam sterilization. A total of 72 specimens (n = 6 per material and specimen design) were stored on malt agar at 20 °C/65% RH and used for mass correction. As virulence control, Scots pine sapwood and European beech were used. The specimens were incubated for 16 weeks with the following test fungi:

-

Coniophora puteana (Schumach.) P. Karst. (Eberswalde 15),

-

Rhodonia placenta (Fr.) Niemelä, K.H. Larsson & Schigel (FPRL 280),

-

Gloeophyllum trabeum (Pers.:Fr.) Murrill (Eberswalde 109),

-

Trametes versicolor (L.) Lloyd. F. (CTB 863a),

-

Pleurotus ostreatus (Jacquin ex Fries) Kummer (FPRL 40C).

After harvesting, the specimens were cleaned from adhering mycelium, weighed, oven-dried at 103 ± 2 °C, and weighed again. The mass loss due to fungal decay (ML) and the material moisture content (MC) were calculated using Eqs. (3) and (4).

where m0 = the initial oven-dry mass before incubation [g], mi = the wet mass after incubation [g], mi,0 = the oven-dry mass after incubation [g].

2.4 Durability assessment

For each group, the arithmetic mean and median ML were calculated. In addition, x-values were computed using Eq. (5):

where MLmed, test = the median mass loss after incubation [%], MLmed, reference = the median mass loss after incubation of Scots pine sapwood to C. puteana, G. trabeum, R. placenta and beech wood to T. versicolor and P. ostreatus [%].

The decay susceptibility index (DSI) was computed using Eq. (6).

where T = mass loss of an individual specimen [%], S = arithmetic mean percentage mass loss of the mass control specimens for each fungus (Scots pine sapwood for C. puteana, G. trabeum, R. placenta and beech wood for T. versicolor and P. ostreatus) [%].

Thereafter, DC were assigned to the groups according to Table 1.

2.5 Statistics

The statistical computing and graphics were made using the software R (RStudio Team 2022).

Boxplots were used to illustrate the distribution of the data set. The median is between the lower (where 25% of the data is less than this value) and upper (where 25% of the data is higher than this value) quartiles of the dataset. The minimum and maximum value are shown by the two outermost lines, while the outliners are represented by dots.

The linear correlation was assessed using the Pearson correlation coefficient (r). Positive correlation is between 0 and 1, 0 indicates no correlation, and between 0 and −1 is a negative correlation.

3 Results and discussion

3.1 Test validity

The fungi C. puteana, G. trabeum, and R. placenta caused a mass loss (ML) of more than 20% on the virulence control specimens of Scots pine sapwood as well as T. versicolor and P. ostreatus on beech solid wood (as required in EN 113-3 2021). Moreover, the median ML of beech solid wood exposed to C. puteana exceeded 30% as required for at least one test fungus.

3.2 Durability of acetylated beech LVL

Acetylated beech LVL proved to be very durable (DC 1), no matter to which fungi it was exposed nor which specimen design and durability assessment was applied (Fig. 2 and Table 2). This coincides with findings from previous studies with acetylated solid wood from various species (Bollmus 2015; Brelid and Simonson 1999; Fodor et al. 2022; Hill et al. 2009; Mantanis et al. 2020; Militz 1991; Rowell 2016; Temiz et al. 2006). In contrast, some others reported that acetylated wood degradation is only inhibited (Alfredsen et al. 2016; Hill et al. 2005). For instance, after 28 weeks of exposure to R. placenta, acetylated Radiata pine (Pinus radiata) showed significant ML under optimum relative humidity and temperature conditions (Beck et al. 2018). In contrast, field tests have shown that acetylated wood and wood products can last for many years, even in soil contact without signs of decay (Brelid et al. 2000; Fodor et al. 2022; Mantanis et al. 2020).

The enhanced biological durability of acetylated wood has been explained by the following potential modes of protective action: (1) wooden cell wall polymers are not recognized by fungal enzymes, (2) nutrients, such as hemicelluloses, are not easily accessible because they are blocked or modified, (3) micropores in the wood cells are blocked, hindering the fungi to pass and reach the nutrients, (4) hydrolysis of polysaccharides is inhibited because less –OH groups are available, and (5) the MC in the cell wall is insufficiently low for the transport of enzymes of decay fungi (Ringman et al. 2014, 2019; Zelinka et al. 2016, 2022). The theory that acetylation renders wood polymers unrecognizable to fungi was recently debunked (Zelinka et al. 2022). For example, a reduced acetyl content was discovered during the fungal decay of acetylated wood, indicating that fungi were able to remove acetylated wood or cleave off acetyl groups from polymers (Beck et al. 2018; Zelinka et al. 2022). The dominating theory for decay inhibition of acetylated wood seems to be the reduced MC in the cell wall (Zelinka et al. 2022).

As expected, untreated beech and beech LVL references were not durable against almost all used test fungi. The phenol layers in the LVL, which were hypothesized to serve as a chemo-mechanical barrier between two veneer sheets, did not provide adequate protection against the fungi.

The highest ML on both larch solid wood and larch 3-layer slabs was caused by the brown rot fungus C. puteana (Fig. 2 and Table 2). Consequently, DCs were assigned based on this test fungus. Larch solid wood was less durable (DC 4) and larch 3-layer slabs were non-durable (DC 5) each based on the median ML. In contrast, European larch is moderate to less durable (DC 3–4) according to EN 350 (2016). However, the direct comparison in this study showed that acetylated beech is remarkably more durable than one of the conventional cladding and construction materials, be it in the form of solid wood or veneer-based panel.

3.3 Effect of specimen design and assessment method on the durability classification

After 16 weeks of incubation, ML varied not only between test fungi and materials, but also between specimen designs (Fig. 2). Generally, the highest ML was achieved with specimens of 15 × 25 × 50 mm3, followed by unsealed specimens of 50 × 50 × 19 mm3, and the latter with edge sealant. This ranking was expected since the larger specimens (EN 113-3 2021) had almost the double volume of the smaller specimens (EN 113-2 2021). In addition, the surface–volume ratio (S/V) of the latter was 2.53 and thus higher compared to 1.85 for the unsealed and 1.05 for the sealed specimens of 50 × 50 × 19 mm3.

In this study, an increased S/V was also frequently associated with an increased ML (Fig. 3). However, for some combinations, the opposite was found. Samples with a S/V of 1.05 showed greater ML than specimens with a surface to volume ratio of 2.53.

In a previous study, Brischke et al. (2021) compared the effect of different specimen sizes and geometries on the ML, x-values and resulting DCs of European larch heartwood. Their results showed that ML is well correlated with the specimens’ S/V. Maximum ML was achieved with specimens having a S/V between 3 and 5. Since both specimen designs with the size of 50 × 50 × 19 mm3 (with and without sealant) had smaller S/V compared to the EN 113-2-specimens, it was not surprising that both ML and x-values were smaller, but DCs partly higher. Differences in DCs between the three specimen designs were only few, which might be explained with the tested materials being either ‘very durable’ (i.e. acetylated beech and beech LVL) or ‘non-durable’ (i.e. Scots pine sapwood, beech, beech LVL). Solely the larch materials were supposed to be ‘less to moderately durable’. As can be seen from the range of ML and x-values respectively for the different DCs in Table 1, the probability to end up with a different DC at a given shift in ML is higher within DC 2 and 3 compared to DC 1, 4, and 5. Consequently, the effect of the specimen geometry was more prominent with larch solid wood and the larch 3-layer slab.

In addition to the varying S/V, the specimens had different portions of end-grain surface which allows for longitudinal penetration of the fungal hyphae, which is the preferred anatomical direction for both fungal growth and water transport (Brischke and Alfredsen 2020; Huckfeldt and Schmidt 2015). Hence, lower ML and thus higher durability of the edge-sealed specimens can be explained with the entire exclusion of longitudinal pathways.

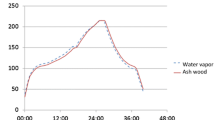

Leaching of test specimens prior to fungal exposure can affect the ML through fungal decay (Aloui et al. 2004; Curling and Murphy 1999). Therefore, ML by leaching was determined and compared between the different specimen designs (Fig. 4). The relative ML by leaching was not significantly different between specimens of 50 × 25 × 15 mm3 and 50 × 50 × 19 mm3. This suggests that the leaching of water-soluble compounds may only be a minor contributor to differences in durability between specimens of varying volumes.

Mass loss during leaching (ΔmL) after 2 weeks of storing in water based on EN 84 (2020)

The median and mean ML correlated perfectly (Fig. 5). In only four out of 30 cases the classification differed by one DC, but in both directions (Table 2). This coincides with previous studies (Bollmus et al. 2014; Brischke et al. 2022) where only marginal differences in durability classification were found between the use of mean and median ML as a basis. However, the use of the median ML for durability classification shall be preferred since it diminishes the effect of outliers. Furthermore, it should also be the basis for calculating x-values, DSI, and other derived parameters serving as the basis for assigning DCs.

The DSI is not meant to use as the basis for durability classification. However, a few attempts to achieve this have been made. For instance, Bicke (2019) compared DCs of chemically modified timber on the basis of the mean ML (x-values) and the DSI, where the use of the latter led rather often to lower durability. The DSI was not classified for durability in this study, but it correlated well with the x-value (Fig. 5).

4 Conclusion

The arithmetic mean and median percentage ML, the x-values, and the DSI were used to assess the durability of acetylated beech LVL using three specimen geometry designs against five wood-destroying basidiomycete monocultures. Acetylation of beech veneers with acetic anhydride highly improves the durability of the manufactured LVL. The material was assigned to DC 1 independent of the applied specimen design and shape as well as test fungi. References like solid larch wood were less durable (DC 4) in comparison. A chemo-mechanical barrier against wood-destroying fungi between the veneer layers was not provided by the phenol adhesive, as evidenced by the fact that the sealed reference LVL was not durable (DC 5).

The mass loss was influenced by the sample size; essentially, the smaller the S/V ratio, the greater the mean and median mass loss. The tested larch solid wood and 3-layer slab demonstrated this effect the most. The leaching of water-soluble components appears to be a small contributor to this effect.

The DC was impacted by the assessment method, and to prevent outliers, median mass loss over mean mass loss should be calculated. Considering their strong correlation, the x-value DC assessment method could be used as a basis to categorize the DSI.

Even though it was found that the shape and specimen design impact on the ML during fungal decay, more representative materials like chipboards, MDF, OSB, and plywood should be tested to validate and better quantify these effects.

Overall, it can be stated that acetylated beech LVL is very durable (DC 1) against wood-destroying fungi. Due to the reduced wood-moisture interaction the dimensional stability is also improved compared to unmodified LVL. This might cause less cracks during outdoor exposure on the material. Moreover, the mechanical properties are relatively high compared to LVL made out of softwood species.

However, the increased density due to additional acetyl groups and high production costs can be seen as possible drawbacks. Moreover, swelling and shrinking continue to occur despite the high ASE. This needs to be considered during outdoor exposure due to moisture changes, which requires a though bonding to avoid delamination.

It is suggested to evaluate the performance of the material in real-life scenarios. One such real-life example might involve exposing acetylated beech LVL outdoor for several years at different locations. Thus, factors like weathering, UV radiation, and moisture changes have an impact on the material. Moisture traps could be taken into consideration to intensify the test.

Data availability

The data used in this study is available from the corresponding author on reasonable request.

References

Alfredsen G, Pilgård A, Fossdal CG (2016) Characterisation of Postia placenta colonisation during 36 weeks in acetylated southern yellow pine sapwood at three acetylation levels including genomic DNA and gene expression quantification of the fungus. Holzforschung 70:1055–1065. https://doi.org/10.1515/hf-2016-0009

Aloui F, Ayadi N, Charrier F, Charrier B (2004) Durability of European oak (Quercus petraea and Quercus robur) against white rot fungi (Coriolus versicolor): relations with phenol extractives. Holz Roh Werkst 62:286–290. https://doi.org/10.1007/s00107-004-0489-7

Amusant N, Arnould O, Pizzi A, Depres A, Mansouris RH, Bardet S, Baudassé C (2009) Biological properties of an OSB eco-product manufactured from a mixture of durable and non durable species and natural resins. Eur J Wood Prod 67:439. https://doi.org/10.1007/s00107-009-0335-z

Beck G, Thybring EE, Thygesen LG (2018) Brown-rot fungal degradation and de-acetylation of acetylated wood. Int Biodeterior Biodegradation 135:62–70. https://doi.org/10.1016/j.ibiod.2018.09.009

Bicke S (2019) Dimensionsstabile und pilzresistente Furnierwerkstoffe durch Zellwandmodifizierung mit niedermolekularem Phenol-Formaldehyd [Dimensionally stable and fungi-resistant veneer-based materials through cell wall modification with low-molecular phenol-formaldehyde]. Dissertation. Georg-August-Universität Göttingen

Bollmus S (2015) Acetylation of German hardwoods. Presented at the 8th European conference on wood modification, Finland

Bollmus S, Gellerich A, Brischke C, Melcher E (2014) Bestimmung der natürlichen Dauerhaftigkeit von Holz. Holztechnologie 55:44–51

Bongers F, Alexander J, Marcroft J, Crawford D, Hairstans R (2013) Structural design with Accoya wood. Int Wood Prod J 4:172–176. https://doi.org/10.1179/2042645313Y.0000000041

Bongers F, Meijerink T, Lütkemeier B, Lankveld C, Alexander J, Militz H, Lehringer C (2016) Bonding of acetylated wood. Int Wood Prod J 7:102–106. https://doi.org/10.1080/20426445.2016.1161944

Brelid PL, Simonson R (1999) Acetylation of solid wood using microwave heating. Holz Roh Werkst 57:383–389. https://doi.org/10.1007/s001070050364

Brelid PL, Simonson R, Bergman Ö, Nilsson T (2000) Resistance of acetylated wood to biological degradation. Holz Als Roh Werkstoff 58:331–337. https://doi.org/10.1007/s001070050439

Brischke C, Alfredsen G (2020) Correction to: wood–water relationships and their role for wood susceptibility to fungal decay. Appl Microbiol Biotechnol 105:6121–6121. https://doi.org/10.1007/s00253-021-11408-6

Brischke C, Grünwald LK, Bollmus S (2021) Correction to: effect of size and shape of specimens on the mass loss caused by Coniophora puteana in wood durability tests. Eur J Wood Prod 79:1659–1659. https://doi.org/10.1007/s00107-021-01730-1

Brischke C, von Boch-Galhau N, Bollmus S (2022) Impact of different sterilization techniques and mass loss measurements on the durability of wood against wood-destroying fungi. Eur J Wood Prod 80:35–44. https://doi.org/10.1007/s00107-021-01745-8

Chao Y-Y, Hung K-C, Xu J-W, Wu T-L, Wu J-H (2020) Effects of acetylated veneer on the natural weathering properties of adhesive-free veneer overlaid wood–plastic composites. Polymers 12:513. https://doi.org/10.3390/polym12030513

Curling SF, Murphy RJ (1999) The effect of artificial ageing on the durability of wood-based board materials against basidiomycete decay fungi. Wood Sci Technol 33:245–257. https://doi.org/10.1007/s002260050113

Dunningham EA, Plackett DV, Singh AP (1992) Weathering of chemically modified wood. Holz Roh Werkst 50:429–432. https://doi.org/10.1007/BF02662780

EN 113-2:2021-02 (2021) Durability of wood and wood-based products—test method against wood destroying basidiomycetes—part 2: assessment of inherent or enhanced durability. Beuth Verlag GmbH, Berlin

EN 113-3:2021-10 (2021) Durability of wood and wood-based products—test method against wood destroying basidiomycetes—part 3: assessment of durability of wood-based panels. Beuth Verlag GmbH, Berlin

EN 350:2016-12 (2016) Durability of wood and wood-based products—testing and classification of the durability to biological agents of wood and wood-based materials. Beuth Verlag GmbH, Berlin

EN 84:2020-10 (2020) Durability of wood and wood-based products—accelerated ageing of treated wood prior to biological testing—leaching procedure. Beuth Verlag GmbH, Berlin

ENV 12038:2002-07 (2002) Durability of wood and wood-based products—wood-based panels—method of test for determining the resistance against wood-destroying basidiomycetes. Beuth Verlag GmbH, Berlin

Evans PD, Wallis AFA, Owen NL (2000) Weathering of chemically modified wood surfaces. Wood Sci Technol 34:151–165. https://doi.org/10.1007/s002260000039

Fodor F, Bak M, Bidló A, Bolodár-Varga B, Németh R (2022) Biological durability of acetylated hornbeam wood with soil contact in Hungary. Forests 13:1003. https://doi.org/10.3390/f13071003

Frihart C, Brandon R, Beecher J, Ibach R (2017) Adhesives for achieving durable bonds with acetylated wood. Polymers 9:731. https://doi.org/10.3390/polym9120731

Hill CAS (2006) Wood modification: chemical, thermal and other processes. Wiley series in renewable resources. John Wiley & Sons, Chichester, England

Hill CAS, Forster SC, Farahani MRM, Hale MDC, Ormondroyd GA, Williams GR (2005) An investigation of cell wall micropore blocking as a possible mechanism for the decay resistance of anhydride modified wood. Int Biodeterior Biodegradation 55:69–76. https://doi.org/10.1016/j.ibiod.2004.07.003

Hill CAS, Curling SF, Kwon JH, Marty V (2009) Decay resistance of acetylated and hexanoylated hardwood and softwood species exposed to Coniophora puteana. Holzforschung. https://doi.org/10.1515/HF.2009.124

Huckfeldt T, Schmidt O (2015) Hausfäule- und Bauholzpilze Diagnose und Sanierung [House rot and timber fungi: diagnosis and remediation], 2nd edn. Müller, Köln

Imamura Y, Nishimoto K (1986) Resistance of acetylated wood to attack by subterranean termites. Wood Res 72:37–44

Mantanis GI, Lykidis C, Papadopoulos AN (2020) Durability of Accoya wood in ground stake testing after 10 years of exposure in Greece. Polymers 12:1638. https://doi.org/10.3390/polym12081638

Militz H (1991) Die Verbesserung des Schwind- und Quellver-haltens und der Dauerhaftigkeit von Holz mittels Behandlung mit unkatalysiertem Essigsäureanhydrid [The improvement of shrinking and swelling behavior and wood durability by treatment with uncatalyzed acetic anhydride]. Holz Roh Werkst 49:147–152. https://doi.org/10.1007/BF02607895

Mohebby B, Talaii A, Najafi SK (2007) Influence of acetylation on fire resistance of beech plywood. Mater Lett 61:359–362. https://doi.org/10.1016/j.matlet.2006.04.117

Olaniran SO, Clerc G, Cabane E, Brunner AJ, Rüggeberg M (2021) Quasi-static and fatigue performance of bonded acetylated rubberwood (Hevea brasiliensis, Müll. Arg.). Eur J Wood Prod 79:49–58. https://doi.org/10.1007/s00107-020-01610-0

Ringman R, Pilgård A, Brischke C, Richter K (2014) Mode of action of brown rot decay resistance in modified wood: a review. Holzforschung 68:239–246. https://doi.org/10.1515/hf-2013-0057

Ringman R, Beck G, Pilgård A (2019) The importance of moisture for brown rot degradation of modified wood: a critical discussion. Forests 10:522. https://doi.org/10.3390/f10060522

Rowell R (2014) Acetylation of wood—a review. Int J Lignocell Prod. https://doi.org/10.22069/ijlp.2014.1920

Rowell R (2016) Dimensional stability and fungal durability of acetylated wood. J Drewno Prace Naukowe Doniesienia Komunikaty 59:139–150. https://doi.org/10.12841/wood.1644-3985.C14.04

Rowell R, Imamura Y, Kawai S, Norimoto M (1989) Dimensional stability, decay resistance, and mechanical properties of veneer-faced low-density particleboards made from acetylated wood. Wood Fiber Sci 21(1):67–79

RStudio Team (2022) RStudio: integrated development environment for R. Posit Software. PBC formerly RStudio, PBC, Boston, MA

Slabohm M, Militz H (2022a) Bonding performance of hot-bonded acetylated beech (Fagus sylvatica L.) laminated veneer lumber (LVL). Wood Mater Sci Eng 18(1):76–81. https://doi.org/10.1080/17480272.2022.2124544

Slabohm M, Militz H (2022b). Improving durability and dimensional stability of beech (Fagus sylvatica L.) LVL by acetylation with acetic anhydride. In: Proceedings of 10th European conference on wood modification, Nancy, France, pp 217–225

Slabohm M, Mai C, Militz H (2022a) Bonding acetylated veneer for engineered wood products—a review. Materials 15:3665. https://doi.org/10.3390/ma15103665

Slabohm M, Mayer AK, Militz H (2022b) Compression of acetylated beech (Fagus sylvatica L.) laminated veneer lumber (LVL). Forests 13:1122. https://doi.org/10.3390/f13071122

Temiz A, Terziev N, Jacobsen B, Eikenes M (2006) Weathering, water absorption, and durability of silicon, acetylated, and heat-treated wood. J Appl Polym Sci 102:4506–4513. https://doi.org/10.1002/app.24878

Treu A, Bredesen R, Bongers F (2020) Enhanced bonding of acetylated wood with an MUF-based adhesive and a resorcinol-formaldehyde-based primer. Holzforschung 74:382–390. https://doi.org/10.1515/hf-2019-0056

Vick CB, Rowell RM (1990) Adhesive bonding of acetylated wood. Int J Adhes Adhes 10:263–272. https://doi.org/10.1016/0143-7496(90)90044-X

Wagenführ R (2007) Holzatlas [Wood atlas], 6th edn. Fachbuchverl. Leipzig im Hanser Verl, Leipzig

Wang Y, Wang T, Crocetti R, Wålinder M (2021) Mechanical properties of acetylated birch plywood loaded parallel to the face grain. Santiago, Chile

Wang Y, Wang T, Crocetti R, Wålinder M (2022) Experimental investigation on mechanical properties of acetylated birch plywood and its angle-dependence. Constr Build Mater 344:128277. https://doi.org/10.1016/j.conbuildmat.2022.128277

Zelinka SL, Ringman R, Pilgård A, Thybring EE, Jakes JE, Richter K (2016) The role of chemical transport in the brown-rot decay resistance of modified wood. Int Wood Prod J 7:66–70. https://doi.org/10.1080/20426445.2016.1161867

Zelinka SL, Altgen M, Emmerich L, Guigo N, Keplinger T, Kymäläinen M, Thybring EE, Thygesen LG (2022) Review of wood modification and wood functionalization technologies. Forests 13:1004. https://doi.org/10.3390/f13071004

Acknowledgements

The authors gratefully acknowledge Accsys Technologies (Arnhem, The Netherlands), Deutsche Holzveredelung Schmeing GmbH & Co., KG (Kirchhundem, Germany), and Dynea AS for providing the different test materials. Antonia Möller, Arne Beulshausen, Caroline M. C. Caesar, Edina Voss, Eva S. Maicher, Hanna Purps, and Petra Heinze are acknowledged for their support with the durability tests. This research was funded by Fachagentur Nachwachsende Rohstoffe e. V. (2220HV049B and 2219NR372).

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

Conceptualization CB and MS; sample preparation MS; formal analysis and visualization CB and MS; writing—original draft preparation CB and MS; writing—review and editing, CB, HM, MS. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Slabohm, M., Brischke, C. & Militz, H. The durability of acetylated beech (Fagus sylvatica L.) laminated veneer lumber (LVL) against wood-destroying basidiomycetes. Eur. J. Wood Prod. 81, 911–921 (2023). https://doi.org/10.1007/s00107-023-01962-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-023-01962-3