Abstract

The hygroscopic and electrical properties of the wood surface of Norway spruce (Picea abies (L.) Karst.) and common beech (Fagus sylvatica L.) were altered by the application of differently concentrated NaCl aqueous solutions. The presence of Na+ and Cl– ions increased the equilibrium moisture content in both woods in environments with a relative humidity of 75% to a nearly saturated state. The electrical resistance of the wood decreased, while the electrical capacitance of the wood increased with increasing amounts of NaCl introduced. Inverse trends were observed for both properties in wood modified with the two most concentrated solutions (18 and 36% molality). Microscopic analysis of the outer layers of the wood samples using scanning electron microscopy and energy-dispersive X-ray spectroscopy showed that the amount of NaCl decreased linearly up to about 1 mm from the modified surface. The presence of Na+ and Cl– ions in wood increased the intensity and improved the homogeneity of the plasma discharge generated during treatment of samples in air at atmospheric pressure. Both modification of wood with NaCl and subsequent treatment with plasma increased the surface roughness of the substrates. Finally, it was shown that the wettability of wood with a waterborne coating was improved after plasma treatment, regardless of the presence of NaCl on the surface. These findings have a good potential not only for the study of surface treatment processes of wood with plasma discharges, but also for other technical applications of lignocellulosic materials.

Similar content being viewed by others

1 Introduction

Knowledge of the dielectric properties of wood is essential for its efficient use in many engineering applications (Sahin and Ay 2004; Sahin Kol 2009), like for instance, the processes including application of electrical energy to heating, drying, and gluing of wood. Dielectric properties of wood are also important for diagnostic purposes, like for example when measuring the moisture content (MC) and thickness of timber, in the detection of defects, decay, discolorations, sapwood area, pasteurization of wood to eradicate exotic pest infestations in lumber, checking strength characteristics, or nondestructive estimation of surface roughness (Sikder et al. 2009; Zhou et al. 2013; Goncz et al. 2018). Wood and its derivatives have also attracted much research interest as electrode materials for electrochemical energy storage devices, including sodium-ion batteries (Huang et al. 2019). Dielectric properties of wood are affected by macroscopic (e.g. fiber direction) and microscopic properties (e.g. porosity), as well as chemical constituents (e.g. chemical additives) (Norimoto 1976; Simpson and TenWolde 1999; Daian et al. 2006; Razafindratsima et al. 2017). Applied voltage, orientation and frequency of the electric field with respect to the structure, temperature, air humidity, and frequency at determination also play an important role (Torgovnikov 1992; Olmi et al. 2010; Daian et al. 2005; Bogosanovic et al. 2010; Brischke and Lampen 2014). The conductivity and dielectric properties of wood increase with increasing amount of water in wood (Kabir et al. 1998; Sahin and Ay 2004; Şahin Kol 2009; Konopka et al. 2018), which varies greatly especially below fiber saturation point (Romanov 2006; Otten et al. 2017).

The principal functions of wood coatings forming protective barrier films are to protect the wood surface against photochemical deterioration and to maintain its desired appearance. Due to inconsistent surface of wood structure, the coating adhesion on the wood surface can be challenging (Peng and Zhang 2019). Therefore, proper preparation of the wood surface prior to the coating process is essential (Oukach et al. 2020). Protection of wood against deterioration can be improved by modification with various inorganic treatments prior to coating application (Suleman and Rashid 1997; Graziola et al. 2012). Modification of wood by sodium chloride (NaCl) improves its resistance to insects and fungi, and provides a surface protection as well (Williams and Feist 1985). In this manner, common availability, low cost, simple preparation and application process of NaCl aqueous solution exhibit a good potential for further research. Depending on the concentration and properties of salt solution, it significantly influences the MC of wood in the upper hygroscopic region (relative humidity = above 75%), where it starts to absorb airborne water (Hertel 1997; Pařil and Dejmal 2014; Konopka et al. 2018; Pouzet et al. 2019). During modification of wood with NaCl, its solution penetrates in wood very well and NaCl can crystallize in wood after drying, while the adsorbed and free water present in wood works as a solvent for NaCl (Lesar et al. 2009). Wood containing water-soluble salts or other electrolytic substances is electrically more conductible than normal wood (Simpson and TenWolde 1999). In highly diluted solutions, cations and anions can be regarded as separate and non-interacting entities. However, in concentrated solutions, the extent and the impact of ion-pairing in aqueous ion chemistry are challenging to understand (Hou et al. 2013; Tandy et al. 2016). An increase in concentration of NaCl in aqueous solutions leads to the decrease in pH value and therefore higher availability of H+ ions (Lima et al. 2017). The density of the samples increases with an increasing concentration of NaCl, while such a modification has a positive effect on the dimensional stability of wood (Pařil and Dejmal 2014). The introduction of NaCl ions into wood increases its conductivity and dielectric constant (Sikder et al. 2009).

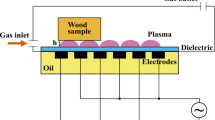

Wood hydrophilicity is a necessary condition for sufficient adhesion of applied water-based coatings. As a method for surface activation of lignocellulosic materials to enhance their wettability with electrical discharge, plasma treatment (PT) is one of the most sophisticated techniques (Král et al. 2015; Novák et al. 2018a; Žigon et al. 2018). Cold atmospheric plasma sources are most suitable for treatment of wood, due to their high productivity, minimal environmental impact, and cost-efficiency (Novák et al. 2018b; Jnido et al. 2019). Plasmas can be defined as completely or partially ionized gases that have a collective behavior. The exposure of a substrate to PT causes physical–chemical transformations on the surface of treated material. This includes the bombardment by energetic species (electrons, ions, free radicals and photons) present in plasma discharge, which carry energies high enough to alter chemical bonds on substrates (Yuan et al. 2004). Dielectric barrier discharge (DBD) plasma is a special type of plasma reactor, which can be used for treatment of wood surfaces (Žigon et al. 2018). Here, the substrate is placed in-between two high voltage electrodes, of which at least one is covered with dielectric barrier. The appearance (i.e. distribution of charges on the electrodes, streamers distribution or discharge self-organization) and other properties of the plasma are highly dependent on the properties and conditions in the plasma reactor (Conrads and Schmidt 2000; Rehn and Viöl 2003), as well as on the wooden substrate’s dielectric properties (Levasseur et al. 2014; De Cademartori et al. 2015).

In previous studies (Žigon and Dahle 2019; Žigon et al. 2019a, b), it was noticed that during PT process of wood in air at atmospheric pressure, plasma streamers are more frequently present in the regions of latewood. Similar observations were reported by Levasseur et al. (2014), where PT of wood was performed in hydrogen atmosphere.

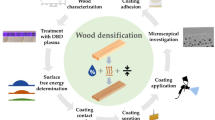

The objective of this research was to improve the effect of PT on wood surface pre-modified with NaCl. It was hypothesized that the combined effect of both treatments could additionally improve the wettability of wood with coating. As schematically presented in Fig. 1, the idea was to improve the electrical conductivity of wood with incorporation of additional ions in the wood structure, and consequently influence the PT process of wood. The wood of Norway spruce (Picea abies (L.) Karst.) and common beech (Fagus sylvatica L.) was modified by application of NaCl aqueous solutions of various concentrations. Firstly, the effect of the NaCl presence in wood on its sorption properties was evaluated from its dry to saturated state. The electrical properties of modified wood were determined via measurements of its resistance and capacitance. The presence of introduced NaCl along the depth of woods was studied by scanning electron microscopy and energy-dispersive X-ray spectroscopy analysis. Electrical properties of wood were also evaluated indirectly via the discharge appearance during PT process. This included the study of discharge intensity and homogeneity, as well as the properties of emitted light with optical emission spectroscopy. The presence of NaCl and treatment with plasma on the wood surface morphology were studied by confocal laser scanning microscopy. Finally, the possible enhancement of wettability of wood with a surface protective water-based coating was evaluated with contact angle measurements.

2 Materials and methods

2.1 Wood materials

Depending on the part of experimental work, wood free of macroscopic defects such as knots and splits of Norway spruce or common beech was used. All further analyses in this study were performed on the planed samples’ surfaces with radial orientation of wood fibers. Prior to the start of the experiments, material was conditioned in the chamber at a temperature of 20 °C and relative humidity (RH) of 65%. The samples reached a certain equilibrium MC (12.1% for spruce wood and 10.8% for beech wood) and nominal density (561 kg m–3 for spruce wood and 713 kg m–3 for beech wood), both determined by gravimetry.

2.2 Preparation and application of NaCl aqueous solutions on surfaces of the samples

Solutions of NaCl (purity ≥ 99.5%, Honeywell, Charlotte, North Carolina, USA) in deionized water of five different mixing ratios (Table 1) were prepared and properly mixed until complete dilution of the solute. The mass fraction w was calculated as follows:

while mixing ratio of NaCl in deionized water was calculated as follows:

In all analyses of this study, the aqueous solutions of NaCl were applied to the samples by dipping each sample in the solution for 3 s, which assured the complete coverage of the samples with the solution.

2.3 Determination of wood moisture content (MC) and sorption properties

Due to hygroscopic properties of NaCl, it is expected that its addition to wood increases wood’s MC at particular RH. Five samples of each type of material of dimensions (10 × 10 × 3) mm3 were stored in climate chambers at a temperature of 20 °C and different RHs, provided by saturated salts: LiCl—11.3%, MgCl2—33.0%, MgNO3—54.1%, NaNO2—65.0%, NaCl—75.3%, KCl—85.0%, ZnSO4—90.0%, K2SO4—97.3% (supplier Merck KGaA, Darmstadt, Germany). The relative equilibrium MC of wood was determined gravimetrically by taking into account the weight of moist sample and the weight of oven dry sample (SIST EN 13183-1 2003). Samples were shifted from lower to higher RH for adsorption, or reversely for desorption properties, after the change between two successive weights measurements did not exceed 0.1%.

2.4 Electrical resistance measurements

For determination of electrical resistivity characteristics, ten replicates per series of both wood species with dimensions of (60 × 30 × 15) mm3 were prepared. Two steel nails, presenting measuring electrodes, were impressed into a surface with radial orientation of wood texture of each specimen. To avoid crack formation and to perform measurements on the same annual ring, the distance between both nails was 30 mm parallel and 6 mm orthogonal to the grain, as suggested by Brischke et al. (2008). The resistance-based measuring system consisted of a data logger (Materialfox, Scanntronik Mugrauer GmbH, Zorneding, Germany), with an effective range from (2 × 104 to 5 × 108) Ω. The measuring principle was based on the discharge-time-measurement method. First, a capacitor was charged through a small ohmic resistance and then discharged through the material to be measured. Based on the time needed for discharging, the resistance of the material was calculated.

2.5 Electrical capacitance measurements

Electrical capacitance measurements were taken at 23 °C and RH of 50%, with parallel steel plate electrodes connected to LCR instrument (LCR-9063, Voltcraft, Conrad Electronic SE, Wernberg-Köblitz, Germany). After insertion of the sample (50 × 50 × 5) mm3 between the electrodes, the impedance was measured internally and converted to display the corresponding capacitance or inductance value in a range up to 2 nF (nanofarads). The electrical capacitance measurements were performed on five samples of each type of material.

2.6 Scanning electron microscopy (SEM) and energy-dispersive X-ray (EDX) spectroscopy analysis

To determine the penetration depth and the presence of NaCl, the cross-sections of wood were studied with scanning electron microscope FEI Quanta 250 (FEI, Hillsboro, Oregon, USA) with integrated EDX system (AMETEK Inc., Berwyn, Pennsylvania, USA). Due to the most appropriate relation between solubility and concentration, only the samples modified with 15.25% NaCl aqueous solutions (“18”) were analyzed. The surfaces to be observed, were cut on the microtome Leica SM2010R (Leica, Wetzlar, Germany). The micrographs were taken at 100× and 1000× magnifications in a low vacuum (50 Pa), at accelerating voltage of 10.0 kV, a spot size of 3.0 nm, and a beam transition time of 45 μs. Signals were detected and collected with a Large Field Detector (LFD), and with Circular Backscatter Detector (CBS) for elemental analysis with EDX. Elements on the selected spots were identified via TEAM™ EDS Analysis System (EDAX, AMETEK Inc., Berwyn, Pennsylvania, USA), including Na+ (by X-ray energy Kα at 1.04 keV) and Cl– (Kα at 2.62) (Barhoumi et al. 2007; Pivovarova and Andrews 2013). The EDX analysis was performed on four spots of two different samples of a particular type of wood.

2.7 Plasma treatment (PT) process of the wood surfaces

The samples were treated with a device with an FE-DBD non-thermal plasma that generates plasma in air at atmospheric pressure (Žigon et al. 2019a). The parameters of an alternating high voltage (frequency 5 kHz, 15 kV peak voltage) were regulated via a high voltage generator. Plasma was ignited between the surface of the treated workpiece (moving speed 3 mm s–1) and two brass electrodes (diameter of 15 mm) insulated by ceramic hoses (Al2O3, thickness 2.5 mm). In the experiments, the distance between the dielectrics was set to 5 mm, and the distance between the dielectrics and the surface of the workpiece was about 1 mm. The samples passed the plasma discharge only once. Process of PT was performed in room at a temperature of 23 °C and RH of 30%.

2.8 Appearance study and optical diagnosis of the discharges

Discharge appearance during PT of samples was observed with the aim to study the influence of added Na+ and Cl– ions in wood on the intensity of the discharge and distribution of plasma streamers. Photographs of the discharges during the treatment of samples (ten per type of material) were taken with a Nikon D5600 (Nikon, Tokyo, Japan) photo camera (exposure time 1/20 s, f5.6, ISO 5600). The amount and intensity of light along the discharges were studied as a function of grey scale with Fiji software (ImageJ 1.46d, Madison, Wisconsin, USA), as presented in Fig. 2.

Optical emission spectroscopy (OES) is a very popular tool for the diagnosis of reactive plasmas, since it can be performed without physical contact with the plasma. Unique emissions of interest from plasma originate from the emitted photons and electronically excited states of the active plasma species (molecules, atoms and ions). The intensity of the optical emission is determined by both the density of the plasma species involved and the electron energy distribution function (Coburn and Chen 1980; Hou and Jones 2000). The optical spectra, emitted during treatment of unmodified and modified beech wood samples (5 per type of material), were measured with Avantes AvaSpec-3648 (Avantes BV, Apeldoorn, the Netherlands) optical spectrometer with a 3648–pixel CCD detector array and 75 cm focal length. The gap distance between the treated sample surfaces and dielectric of the plasma device was set to 1 mm, while the optical lens was placed 10 mm from the generated discharge. Spectra were recorded with an integration time of 2 s and a resolution of 0.5 nm in the spectral range from 200 to 1100 nm.

Reduced electric fields were evaluated from the nitrogen emission lines N2+(B2Σu+ → X2Σg+, (0, 0)) at 391.4 nm and N2 (C3Πu → B3Πg, (2, 5)) at 394.3 nm according to Paris and colleagues (Paris et al. 2005, 2006; Pancheshnyi 2006; Kuchenbecker et al. 2009). Electron energies were calculated based on the reduced electric fields using the Bolsig + software version 03/2016 (Hagelaar and Pitchford 2005) with cross sections from the LXcat database (Pitchford 2013).

2.9 Analysis of morphology of the surfaces

Microstructure of the freshly prepared samples’ surfaces, before and after application of aqueous NaCl solutions, and after additional PT was studied. Prior to the morphological analyses, the surfaces were evened with the sliding microtome Leica SM2010R. For precision monitoring of the changes, each time the same area of the individual sample was observed with the confocal laser scanning microscope LEXT OLS5000 (Olympus, Tokyo, Japan) with laser light source wavelength 405 nm, at a maximum lateral resolution of 0.12 µm. The mapping images of the areas on the samples’ surfaces were taken at 5-fold magnification (scanned area of about (2560 × 2560) µm). To study the influence of NaCl crystals in aqueous solutions on the surface topography, the latter were applied on a glass plate presenting ideally flat surface, dried in an oven at 102.6 °C for 24 h, and later analyzed. The software OLS50-S-AA (Olympus, Tokyo, Japan) was used to produce topographical images and calculate the roughness parameter Sa (arithmetic mean of the deviations from the mean samples surface).

2.10 Coating contact angle (CA) measurements

The droplets of the water-based commercial coating with surface tension of 30.1 mN m−1 (Belinka Interier, Belinka Belles, d.o.o., Ljubljana, Slovenia), were applied and monitored on the sample surfaces by the Theta optical goniometer (Biolin Scientific Oy, Espoo, Finland). The initial (2 s after application) apparent CAs were measured by Young–Laplace analysis (Young 1805) using the software (OneAttension version 2.4 [r4931], Biolin Scientific Oy, Espoo, Finland). Five coating droplets with a volume of 5 μL were applied on different places of the radial surface on the samples (three replicates per type of material). In the case of plasma-treated samples, the CA measurements were performed immediately after the treatment process to avoid the effects of ageing.

3 Results and discussion

3.1 Wood sorption hysteresis

Sorption hysteresis of normal wood and wood treated with NaCl, determined in the range of RH from 0% to approximately 100%, is presented in Fig. 3. In general, both unmodified wood species turned out to be similarly hygroscopic, which is in agreement with the literature (Rémond et al. 2017). Addition of NaCl aqueous solutions of different concentrations did not affect the wood MC up to RH 75%. However, at a higher RH, the effect of higher NaCl concentration was more noticeable. Here, spruce wood turned out to be more hygroscopic than beech wood. For instance, the application of the most concentrated solution (26.47% or “36”) considerably increased the wood fiber saturation point from 22 to 55% for spruce wood, and from 25 to 42% for beech wood. Similar observation of critical 75% RH on sorption curve of wood impregnated with NaCl was reported by Lesar et al. (2009). The authors of the study assigned this observation to the lowered saturation pressure of the chemical present in wood.

3.2 Electrical resistance

Electrical resistance of spruce and beech wood surfaces decreased with the amount of introduced NaCl (Fig. 4), indicated also by the increase in the samples’ masses. Solutions of concentration of up to 6.72% (“7.2”) caused a linear decrease in electrical resistance. Application of solutions with concentrations of 15.25% (“18”) and 26.47% (“36”) did not further increase the electrical conductivity of the wood surface, although the amount of conductive NaCl in wood increased for 4.5 or 6.0%, respectively.

3.3 Electrical capacitance

It is known that hardwoods have higher relative permittivity than softwoods (Pentoś et al. 2017). The introduction of NaCl into wood surfaces had reciprocal influence on the samples’ electrical capacitance compared to their electrical resistance, as the capacitance increased with the amount of introduced NaCl (Fig. 5). Solutions of concentration of up to 6.72% (“7.2”) caused an increase in the electrical capacitance, but the solution with a concentration of 26.47% (“36”) no longer contributed to higher capacitance, although the amount of NaCl in wood was even higher. It is assumed that the reasons for this are the larger NaCl crystals remaining on the surface (pictures shown in Sect. “3.6”), causing air gaps with low capacitance between the steel plates of LCR meter and wood sample.

3.4 SEM and EDX investigation of wood

SEM micrographs of tangential surfaces of spruce and beech wood, with applied 15.25% NaCl aqueous solution (“18”) on radial surfaces at 100× and 1000× magnifications are shown in Fig. 6. Larger NaCl crystals present in wood are indicated.

SEM micrographs of tangential surfaces of spruce (a) and beech (b) wood at ×100 (left) and ×1000 (right) magnifications. In the left images the arrows indicate the penetration direction of the applied solution from the radial surfaces, corresponding to the direction of EDX analysis for indication of the NaCl penetration depth. NaCl crystals present in the wood structure are indicated by white arrows in the right images

The obtained spectra of EDX analysis with concentrations of Na+ and Cl– elements along the depth of the samples are shown in Figs. 7 and 8. In case of both wood species, the intensity of Na+ and Cl– was the highest in the first 20 µm in depth from the modified surface. Here, the detected intensity of both elements was higher in spruce wood. Further, the detected amount of NaCl linearly decreased with depth. Such trend in tangential direction was found for both wood species up to approximately 1000 µm from the modified surface.

3.5 Appearance and optical properties of the discharges

In general, the appearance of streamers is in good relation with early- and latewood distribution on the cross section of the treated sample. As seen in Fig. 9, this is especially visible during PT of unmodified samples. Regions of latewood have a higher density (Koubaa et al. 2008) and exhibit a higher electrical conductivity than earlywood regions (Stamm 1929, 1931; Zelinka et al. 2015). The detected intensities of the discharge, which is correlated to the power transfer within the corresponding microdischarges, are more pronounced in latewood regions, which exhibit higher average grey values. Addition of Na+ and Cl– ions in wood influenced the discharge appearance (plasma streamers distribution, discharge density and homogeneity) during PT, which was more pronounced on spruce than on beech samples. The measured grey values increased by increment of NaCl solution concentrations of up to 6.72% (“7.2”) or 15.25% (“18”), respectively. For wood modified with 26.47% (“36”) solution, the presence of larger crystals on the surfaces, with higher conductivity than the surrounding modified surface, again negatively affected the homogeneity of the discharges.

To verify what species were present in the discharge zone, the OES technique was used. In Fig. 10, the light spectra obtained by the treatment of unmodified and modified beech samples are presented. In this region of the spectra (290 nm through 410 nm), the most intense second positive system of N2 emission lines from the atmospheric gas can be identified at 316, 354, 358, 375 and 385 nm. The highest peak at 337.1 nm is assigned to N2+ (Laux et al. 2003; Belmonte et al. 2015). The height of all the indicated peaks increased with increasing concentration of NaCl on the wood surface. Light emissions of sodium (at 590 nm) and chloride (at 768 nm) were not identified (Goueguel et al. 2014; Barauna de Oliveira et al. 2017).

In Fig. 11, the average electron energies with the intensity of the strongest nitrogen emission line (at 337.1 nm) and the overall sum of the emitted light intensity are compared. Both, the sum emission intensity and the calculated mean electron energy show a strong peak at 7.2 g dl–1 NaCl, and this is also well represented in all ratios of the emission lines at other significant emission intensities. In contrast to that, the intensity of the line at 337.1 nm rises continuously with increasing NaCl concentration. The likely reason for this is the strong localization of filaments at NaCl crystals on the wood surfaces for the two highest NaCl concentrations. These led to particularly bright filaments on the one hand, whereas on the other hand, the power transfer on other parts of the surface was much reduced. Hence, the average electron energies are reduced, as well. Thus, the point at approx. 7 g dl–1 NaCl seems to represent the optimal point of increased conductivity and dielectric permittivity of the wood substrate, as indicated by the resistance and capacitance measurements. The same concentration seems to be the optimal for NaCl crystal appearance and localization of plasma streamers at the crystals’ sharp edges during PT process.

3.6 Morphology of modified and treated surfaces

Increment of arithmetic mean roughness of glass surface with increase in concentration of applied NaCl aqueous solutions, was also reflected in the surface roughness of modified wood (Fig. 12). Additional treatment with plasma slightly increased Sa of the surfaces; however, here the accuracy of the roughness measurement on the same spots before and after PT, as well as the accuracy of the microscopic technique used may also play a role. Selected topographical maps of unmodified and treated wood surfaces, and wood surfaces modified with 26.47% (“36”) NaCl solutions and treated with plasma, are depicted at the bottom of Fig. 12. Here, larger crystals of NaCl are noticeable. Different colors correspond to different surface heights.

Absolute changes of roughness parameter Sa, measured at fivefold magnification: wood roughness after modification with NaCl solutions and additional PT (columns), and roughness of glass surface with applied NaCl solutions (dots). Bottom row: 3-dimensional topographical images at fivefold magnification, as follows: a spruce unmodified + treated, b spruce modified (“S-36”) + treated, c beech unmodified + treated, d beech modified (“B-36”) + treated

3.7 Coating contact angles

CA of coating droplets, detected 2 s after application on untreated and plasma-treated wood samples are presented in Fig. 13. In general, wettability with coating was improved after PT of wood. Detected initial coating CA were comparable on unmodified wood surfaces and wood surfaces modified with NaCl in lower concentrations (1.77–6.72%). Higher (15.25 and 26.47%) concentrations of NaCl on wood surfaces increased coating CA. The reason for that is most probably increased surface roughness (presence of crystals), which disabled the coating droplet to spread over the surface of the substrates. Considering the span of the error bars by particular column, no larger differences were shown between spruce and beech wood.

4 Conclusion

The study revealed that the introduction of NaCl into wood changes its hygroscopic and electrical properties. The presence of high amounts of NaCl on the surface of Norway spruce wood and common beech wood increases equilibrium moisture content of wood, when exposed to environment with higher relative humidity (from 75% to almost 100%). The electrical resistance of samples linearly decreased with the amount of introduced NaCl during modification. However, on wood modified with 15.25 and 26.47% solutions, the decrease in electrical resistance was no longer detected. A similar trend was observed for the electrical capacitance of modified wood, which increased with the amount of NaCl present inside the material. Again, no further increase was detected for wood modified with the two most concentrated solutions. Microscopic analysis of wood samples’ outer layers showed that the amount of NaCl linearly decreased with distance from modified surface. The penetration depth of NaCl was determined to be about 1 mm. The presence of Na+ and Cl– ions in wood influenced the treatment process with FE-DBD plasma, generated in air at atmospheric pressure. With the higher amount of NaCl in the wood substrate, the discharge in the gap between wood and insulated electrode became more intense and homogenous. Wood arithmetic mean surface roughness increased after application of NaCl. The subsequent treatment of wood with plasma most probably additionally promoted the span of the samples’ surface morphologies. Wettability of wood with water-borne coating was enhanced after PT, regardless of the presence of NaCl on the surface. However, the highest concentration of NaCl on wood made its surface less acceptable for wetting with coating.

It was shown that electrical conductivity of wood can be improved with addition of NaCl in its structure. The modification of wood with NaCl might have a good potential not only by treatment processes of wood with plasma discharges, but also in other engineering applications of wood or any other lignocellulosic materials.

Change history

14 July 2021

A Correction to this paper has been published: https://doi.org/10.1007/s00107-021-01724-z

References

Barauna de Oliveira JBF, Pereira CS, Gonçalves IA, Vitoriano de Oliveira J, Alves JC (2017) Sodium chloride crystallization by electric discharge in brine. Mater Res 20:215–220. https://doi.org/10.1590/1980-5373-mr-2017-0108

Barhoumi Z, Djebali W, Smaoui A, Chaibi W, Abdelly C (2007) Contribution of NaCl excretion to salt resistance of Aeluropus littoralis (Willd) Parl. J Plant Physiol 164:842–850. https://doi.org/10.1016/j.jplph.2006.05.008

Belmonte T, Noël C, Gries T, Martin J, Henrion G (2015) Theoretical background of optical emission spectroscopy for analysis of atmospheric pressure plasmas. Plasma Sources Sci Technol 24(6):29. https://doi.org/10.1088/0963-0252/24/6/064003

Bogosanovic M, Anbuky AA, Emms GW (2010) Overview and comparison of microwave noncontact wood measurement techniques. J Wood Sci 56:357–365. https://doi.org/10.1007/s10086-010-1119-0

Brischke C, Lampen SC (2014) Resistance based moisture content measurements on native, modified and preservative treated wood. Eur J Wood Prod 72:289–292. https://doi.org/10.1007/s00107-013-0775-3

Brischke C, Rapp AO, Bayerbach R (2008) Measurement system for long-term recording of wood moisture content with internal conductively glued electrodes. Build Sci 43:1566–1574. https://doi.org/10.1016/j.buildenv.2007.10.002

Coburn JW, Chen M (1980) Optical emission spectroscopy of reactive plasmas: a method for correlating emission intensities to reactive particle density. J Appl Phys 51:3134–3136. https://doi.org/10.1063/1.328060

Conrads H, Schmidt M (2000) Plasma generation and plasma sources. Plasma Sources Sci Technol 9:441–454. https://doi.org/10.1088/0963-0252/9/4/301

Daian G, Taube A, Birnboim A, Shramkov Y, Daian M (2005) Measuring the dielectric properties of wood at microwave frequencies. Wood Sci Technol 39:215–223. https://doi.org/10.1007/s00226-004-0281-1

Daian G, Taube A, Birnboim A, Daian M, Shramkov Y (2006) Modeling the dielectric properties of wood. Wood Sci Technol 40:237–246. https://doi.org/10.1007/s00226-005-0060-7

De Cademartori GHP, Muniz BIG, Magalhães ELW (2015) Changes of wettability of medium density fiberboard (MDF) treated with He-DBD plasma. Holzforschung 69(2):187–192. https://doi.org/10.1515/hf-2014-0017

Goncz B, Divos F, Bejo L (2018) Detecting the presence of red heart in beech (Fagus sylvatica) using electrical voltage and resistance measurements. Eur J Wood Prod 76:679–686. https://doi.org/10.1007/s00107-017-1225-4

Goueguel C, Singh PJ, McIntyre LD, Jain J, Karamalidis KA (2014) Effect of sodium chloride concentration on elemental analysis of brines by laser-induced breakdown spectroscopy (LIBS). Appl Spectrosc 68(2):213–221. https://doi.org/10.1366/13-07110

Graziola F, Girardi F, Di Maggio R, Callone E, Miorin E, Negri M, Müller K, Gross S (2012) Three-components organic–inorganic hybrid materials as protective coatings for wood: optimisation, synthesis, and characterization. Prog Org Coat 74:479–490. https://doi.org/10.1016/j.porgcoat.2012.01.013

Hagelaar GJM, Pitchford LC (2005) Solving the Boltzmann equation to obtain electron transport coefficients and rate coefficients for fluid models. Plasma Sources Sci Technol 14:722–733. https://doi.org/10.1088/0963-0252/14/4/011

Hertel H (1997) Protection of wood against the house longhorn beetle Hylotrupes bajulus with sodium chloride and potassium chloride. Pestic Sci 49:307–312. https://doi.org/10.1002/(SICI)1096-9063(199703)49:3%3c307::AID-PS522%3e3.0.CO;2-8

Hou X, Jones BT (2000) Inductively coupled plasma/optical emission spectrometry. In: Meyers RA (ed) Encyclopedia of analytical chemistry. Wiley, Chichester, pp 9468–9485

Hou CH, Huang CY, Hu CY (2013) Application of capacitive deionization technology to the removal of sodium chloride from aqueous solutions. Int J Environ Sci Technol 10:753–760. https://doi.org/10.1007/s13762-013-0232-1

Huang J, Zhao B, Liu T, Mou J, Jiang Z, Liu J, Li H, Liu M (2019) Wood-derived materials for advanced electrochemical energy storage devices. Adv Funct Mater 1902255:23. https://doi.org/10.1002/adfm.201902255

Jnido G, Ohms G, Viöl W (2019) Deposition of TiO2 thin films on wood substrate by an air atmospheric pressure plasma jet. Coatings 9(7):441. https://doi.org/10.3390/coatings9070441

Kabir MF, Daud WM, Khalid K, Sidek HAA (1998) Dielectric and ultrasonic properties of rubber wood. Effect of moisture content, grain direction and frequency. Holz Roh- Werkst 56:223–227. https://doi.org/10.1007/s001070050305

Konopka A, Barański J, Orłowski K, Szymanowski K (2018) The effect of full-cell impregnation of pine wood (Pinus sylvestris L.) on changes in electrical resistance and on the accuracy of moisture content measurement using resistance meters. BioResources 13(1):1360–1371. https://doi.org/10.15376/biores.13.1.1360-1371

Koubaa A, Perré P, Hutcheon MR, Lessard J (2008) Complex dielectric properties of the sapwood of aspen, white birch, yellow birch, and sugar maple. Dry Technol 26(5):568–578. https://doi.org/10.1080/07373930801944762

Král P, Ráhel J, Stupavská M, Šrajer J, Klímek P, Mishra KP, Wimmer R (2015) XPS depth profile of plasma–activated surface of beech wood (Fagus sylvatica) and its impact on polyvinyl acetate tensile shear bond strength. Wood Sci Technol 49:319–330. https://doi.org/10.1007/s00226-014-0691-7

Kuchenbecker M, Bibinov N, Kaemlimg A, Wandke D, Awakowicz P, Viöl W (2009) Characterization of DBD plasma source for biomedical applications. J Phys D 42:045212. https://doi.org/10.1088/0022-3727/42/4/045212

Laux CO, Spence TG, Kruger CH, Zre RN (2003) Optical diagnostics of atmospheric pressure air plasmas. Plasma Sources Sci Technol 12:125–138. https://doi.org/10.1088/0963-0252/12/2/301

Lesar B, Gorišek Ž, Humar M (2009) Sorption properties of wood impregnated with boron compounds, sodium chloride and glucose. Dry Technol 27(1):94–102. https://doi.org/10.1080/07373930802565947

Levasseur O, Bouarouri A, Naudé N, Clergereaux R, Gherardi N, Stafford L (2014) Organization of dielectric barrier discharges in the presence of structurally inhomogenous wood substrates. IEEE Trans Plasma Sci 42(10):2366–2367. https://doi.org/10.1109/TPS.2014.2321518

Lima FL, Vieira LA, Mukai M, Andrade GMC, Fernandes GRP (2017) Electric impedance of aqueous KCl and NaCl solutions: salt concentration dependence on components of the equivalent electric circuit. J Mol Liq 241:530–539. https://doi.org/10.1016/j.molliq.2017.06.069

Norimoto M (1976) Dielectric properties of wood. Wood Res Bull Wood Research Inst Kyoto Univ 59(60):106–152

Novák I, Sedlačik J, Kleinová A, Matyašovský J, Jurkovič P (2018a) Oak wood pre-treated by cold plasma. AnnWULS SGGW For Wood Technol 104:167–168

Novák I, Sedlačik J, Kleinová A, Matyašovský J, Jurkovič P (2018b) Discharge plasma treatment of wood surfaces. Ann. WULS SGGW For Wood Technol 104:169–173

Olmi R, Bini M, Ignesti A, Riminesi C (2010) Dielectric properties of wood from 2 to 3 GHz. J Microw Power 35(3):135–143. https://doi.org/10.1080/08327823.2000.11688430

Otten KA, Birschke C, Meyer C (2017) Material moisture content of wood and cement mortars—electrical resistance-based measurements in the high ohmic range. Constr Build Mater 153:640–646. https://doi.org/10.1016/j.conbuildmat.2017.07.090

Oukach S, Hamdi H, El Ganaoui M, Pateyron B (2020) Protective plasma sprayed coating for thermos-sensitive substrates. In: MATEC web of conferences, vol 307, p 01039. https://doi.org/10.1007/s11666-019-00857-1

Pancheshnyi S (2006) Comments on ‘Intensity ratio of spectral bands of nitrogen as a measure of electric field strength in plasmas.’ J Phys D 39:1708. https://doi.org/10.1088/0022-3727/39/8/N01

Pařil P, Dejmal A (2014) Moisture absorption and dimensional stability of poplar wood impregnated with sucrose and sodium chloride. Maderas Ciencia y tecnología 16(3):299–311. https://doi.org/10.4067/S0718-221X2014005000023

Paris P, Aints M, Valk F, Plank T, Haljaste A, Kozlov KV, Wagner H-E (2005) Intensity ratio of spectral bands of nitrogen as a measure of electric field strength in plasmas. J Phys D 38:3894. https://doi.org/10.1088/0022-3727/38/21/010

Paris P, Aints M, Valk F, Plank T, Haljaste A, Kozlov KV, Wagner H-E (2006) Reply to comments on ‘Intensity ratio of spectral bands of nitrogen as a measure of electric field strength in plasmas.’ J Phys D 39:2636. https://doi.org/10.1088/0022-3727/39/12/N01

Peng X-R, Zhang Z-K (2019) Improvement of paint adhesion of environmentally friendly paint film on wood surface by plasma treatment. Prog Org Coat 134:255–263. https://doi.org/10.1016/j.porgcoat.2019.04.024

Pentoś K, Łuczycka D, Wysoczański T (2017) Dielectric properties of selected wood species in Poland. Wood Res 62(5):727–736

Pitchford CL (2013) GEC plasma data exchange project. J Phys D 46:330301. https://doi.org/10.1088/0022-3727/46/33/330301

Pivovarova NB, Andrews SB (2013) Measurement of total calcium in neurons by electron probe X-ray microanalysis. J Vis Exp 81:e50807. https://doi.org/10.3791/50807

Pouzet M, Dubois M, Charlet K, Békou A, Leban JM, Baba M (2019) Fluorination renders the wood surface hydrophobic without any loss of physical and mechanical properties. Ind Crops Prod 133:133–141. https://doi.org/10.1016/j.indcrop.2019.02.044

Razafindratsima S, Sbartaḯ ZM, Demontoux F (2017) Permittivity measurement of wood material over a wide range of moisture content. Wood Sci Technol 51:1421–1431. https://doi.org/10.1007/s00226-017-0935-4

Rehn P, Viöl W (2003) Dielectric barrier discharge treatments at atmospheric pressure for wood surface modification. Holz Roh Werkst 61:145–150. https://doi.org/10.1007/s00107-003-0369-6

Rémond R, Cipriano ABL, Almeida G (2017) Moinsture transport and sorption in beech and spruce barks. Holzforschung 72(2):105–111. https://doi.org/10.1515/hf-2017-0066

Romanov AN (2006) The effect of volume humidity and the phase composition of water on the dielectric properties of wood at microwave frequencies. J Commun Technol Electron 51(4):435–439. https://doi.org/10.1134/S1064226906040115

Sahin H, Ay N (2004) Dielectric properties of hardwood species at microwave frequencies. J Wood Sci 50:375–380. https://doi.org/10.1007/s10086-003-0575-1

Şahin Kol H (2009) Thermal and dielectric properties of pine wood in the transverse direction. BioResources 4(4):1663–1669

Sikder SS, Uddin KA, Rahman MM, Bhuiyan AH (2009) Effect of salinity on dynamic dielectric properties of Sundari wood of Bangladesh. Bangladesh J Phys 7 & 8:55–61

Simpson W, TenWolde A (1999) Physical properties and moisture relations of wood. Wood handbook: wood as an engineering material. USDA Forest Service, Forest Products Laboratory, General technical report FPL; GTR-113, Madison, pp 3.1–3.24

SIST En 3183-1 (2003) Round and sawn timber—method of measurement of moisture content—Part 1: method for determining moisture content of a piece of sawn timber (Oven dry method). Standard, Slovenian Institute for Standardization

Stamm AJ (1929) The fiber-saturation point of wood as obtained from electrical conductivity measurements. Ind Eng Chem Anal Ed 1(2):94–97. https://doi.org/10.1021/ac50066a021

Stamm AJ (1931) An electrical conductivity method for determining the effective capillary dimensions of wood. J Phys Chem 36(1):312–325. https://doi.org/10.1021/j150331a021

Suleman YH, Rashid SH (1997) Chemical treatment to improve wood finishing. Wood Fiber Sci 31(3):300–305

Tandy J, Feng C, Boatwright A, Sarma G, Sadoon AM, Shirley A, Rodrigues NDN, Cunningham EM, Yang S, Ellis AM (2016) Communication: Infrared spectroscopy of salt-water complexes. J Chem Phys 144:121103–1-121103–4. https://doi.org/10.1063/1.4945342

Torgovnikov G (1992) Dielectric properties of wood and wood-based materials. Springer, Berlin, p p196

Williams RS, Feist WC (1985) Wood modified by inorganic salts: mechanism and properties. I. Weathering rate, water repellency, and dimensional stability of wood modified with chromium nitrate versus chromic acid. Wood Fiber Sci 17(2):184–198

Young T (1805) An essay on the cohesion of fluids. Philos Trans R Soc 95:65–87. https://doi.org/10.1098/rstl.1805.0005

Yuan X, Jayaraman K, Bhattacharyya D (2004) Effects of plasma treatment in enhancing the performance of woodfibre-polypropylene composites. Compos Part A 35(12):1363–1374. https://doi.org/10.1016/j.compositesa.2004.06.023

Zelinka SL, Wiedenhoeft AC, Glass SV, Ruffinatto F (2015) Anatomically informed mesoscale electrical impedance spectroscopy in southern pine and the electric field distribution for pin-type electric moisture metres. Wood Mater Sci Eng 10(2):189–196. https://doi.org/10.1080/17480272.2014.934282

Zhou J, Zhou H, Hu C, Hu S (2013) Measurements of thermal and dielectric properties of medium density fiberboard with different moisture contents. BioResources 8(3):4185–4192. https://doi.org/10.15376/biores.8.3.4185-4192

Žigon J, Dahle S (2019) Improvement of plasma treatment efficiency of wood and coating process by sodium chloride aqueous solutions. Proligno 15(4):260–267

Žigon J, Petrič M, Dahle S (2018) Dielectric barrier discharge (DBD) plasma pretreatment of lignocellulosic materials in air at atmospheric pressure for their improved wettability: a literature review. Holzforschung 72(11):972–991. https://doi.org/10.1515/hf-2017-0207

Žigon J, Petrič M, Dahle S (2019a) Artificially aged spruce and beech wood surfaces reactivated using FE-DBD atmospheric plasma. Holzforschung 73(12):1069–1081. https://doi.org/10.1515/hf-2019-0005

Žigon J, Petrič M, Ayata Ü, Zaplotnik R, Dahle S (2019b) The influence of artificial weathering and treatment with FE-DBD plasma in atmospheric conditions on wettability of wood surfaces. In: Proceedings of 3. Niedersächsisches Symposium Materialtechnik, 14. to 15. February 2019, Clausthal-Zellerfeld, Shaker, p 16

Acknowledgements

The authors acknowledge the financial support from the Slovenian Research Agency (research program funding No. P4-0015, “Wood and lignocellulosic composites”). This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No. 745936. The help by OES measurements of Rok Zaplotnik from Jožef Stefan Institute, Ljubljana, Slovenia, and Julia Mrotzek from University of Applied Sciences and Arts, Göttingen, Germany, is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that no conflict of interest exists.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised due to a retrospective Open Access order.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Žigon, J., Petrič, M. & Dahle, S. Dielectric and surface properties of wood modified with NaCl aqueous solutions and treated with FE-DBD atmospheric plasma. Eur. J. Wood Prod. 79, 1117–1128 (2021). https://doi.org/10.1007/s00107-021-01708-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-021-01708-z