Abstract

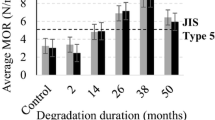

This research examined beech bark from a plywood manufacturer to determine its effectiveness in reducing wastes, protecting the ecological environment, and producing more eco-friendly wood-based materials. Beech bark was characterized and evaluated as an adhesive filler in plywood manufacturing, and the effects on the bonding quality and the formaldehyde emission of the plywood panels were examined. Plywood panels were made of formulations with urea-formaldehyde (UF) resin filled with three different concentrations of bark flour (BF): 1 wt%, 3 wt%, and 5 wt%. Compared with solid beech wood, beech bark has a higher lignin and extractives content and lower holocellulose content. It was confirmed that the bark absorbs formaldehyde and the solution with 5 wt% of bark absorbed the most formaldehyde. Panels with UF/BF formulations at a bark content of 1 wt%, 3 wt%, and 5 wt% had higher wet bonding strengths than those made with the control sample. The most significant reduction in formaldehyde emission (up to 42.3%) of plywood panels and the achievement of high bonding strength was observed for UF/BF samples with a bark concentration of 5 wt%. The bonding strength of plywood panels with all investigated BF concentrations met the requirements of the EN 314-2 standard.

Similar content being viewed by others

References

Al-Dmoor HM, El-Qudah JM (2016) Cake flour chlorination and alternative treatments (review). Curr Res Nutr Food Sci 4(2):127–134. https://doi.org/10.12944/CRNFSJ.4.2.06

Arbenz A, Avérous L (2015) Chemical modification of tannins to elaborate aromatic biobased macromolecular architectures. Green Chem 17:2626–2646

Aydin I, Demirkir C, Colak S, Colakoğlu S (2017) Utilization of bark flours as additive in plywood manufacturing. Eur J Wood Prod 75:63–69. https://doi.org/10.1007/s00107-016-1096-0

Bekhta P, Sedliačik J, Kačík F, Noshchenko G, Kleinová A (2019) Lignocellulosic waste fibers and their application as a component of urea-formaldehyde adhesive composition in the manufacture of plywood. Eur J Wood Prod 77(4):495–508. https://doi.org/10.1007/s00107-019-01409-8

Benar P, Mandelli D, Gonçalves ARC, Ferreria MMC, Schuchardt U (1999) Principal component analysis on the hydroxymethylation of sugarcane lignin: a time-depending study by FTIR. J Wood Chem Technol 19(1–2):151–165

Bodîrlău R, Teacă CA, Spiridon I (2008) Chemical modification of beech wood: effect on thermal stability. BioResources 3(3):789–800. https://doi.org/10.15376/biores.3.3.789-800

Boran S, Usta M, Ondaral S, Gümüskaya E (2012) The efficiency of tannin as a formaldehyde scavenger chemical in medium density fiberboard. Compos Part B Eng 43:2487–2491. https://doi.org/10.1016/j.compositesb.2011.08.004

Brozdowski J, Waliszewska B, Sieradzka A, Spek-Dzwigala A (2018) Chemical composition of beech bark stripped and not stripped by animals. Ann Warsaw Univ Life Sci For Wood Technol 104:420–425

Buyuksari U, Ayrilmis N, Avci E, Koc E (2009) Evaluation of the physical, mechanical properties and formaldehyde emission of particleboard manufactured from waste stone pine (Pinus pinea L.) cones. Bioresour Technol 101:255–259. https://doi.org/10.1016/j.biortech.2009.08.038

Cetin NS, Ozmen N, Narlioglu N, Cavus V (2014) Effect of bark flour on the mechanical properties of HDPE composites. J Mater Sci 1:23–32. https://doi.org/10.12748/uujms.201416497

Chen N, Zheng P, Zeng Q, Lin Q, Rao J (2017) Characterization and performance of soy-based adhesives cured with epoxy resin. Polymers 9:514. https://doi.org/10.3390/polym9100514

Chupin L, Motillon C, Charrier-El Bouhtoury F, Pizzi A, Charrier B (2013) Characterisation of maritime pine (Pinus pinaster) bark tannins extracted under different conditions by spectroscopic methods, FTIR and HPLC. Ind Crops Prod 49:897–903. https://doi.org/10.1016/j.indcrop.2013.06.045

Colakoglu G, Kalaycioglu H, Ors Y (1993) Utilization of the bark of Turkish red pine on particleboard and plywood manufacturing. In: International Red pine symposium, proceedings, October 18–23, Marmaris, Turkey, pp 701–710

Corder SE (1976) Properties and uses of bark as an energy source. Research Paper 31, Oregon State University, Forest Research Laboratory, Corvallis, OR, USA

Corderio N, Belgacem MN, Gandini A, Neto CP (1997) Urethanes and polyurethanes from suberin: 1. Kinetic study. Ind Crop Prod 6(2):163–167. https://doi.org/10.1016/S0926-6690(96)00212-9

Costa NA, Pereira J, Ferra J, Cruz P, Martins J, Magalhгes FD, Mendes A, Carvalho LH (2013) Scavengers for achieving zero formaldehyde emission of wood-based panels. Wood Sci Technol 47:1261–1272. https://doi.org/10.1007/s00226-013-0573-4

De Jong JI, De Jonge J (1953) Kinetics of the hydroxymethylation of phenols in dilute aqueous solution. Recueil des Travaux Chimiques des Pays Bas 72(6):497–509

de Melo RR, Del Menezzi CHS (2014) Influence of veneer thickness on the properties of LVL from Parica (Schizolobium amazonicum) plantation trees. Eur J Wood Prod 72(2):191–198. https://doi.org/10.1007/s00107-013-0770-8

Dijkstra R, De Jonge J, Lammers MF (1962) The kinetics of the reaction of phenol and formaldehyde. Recueil des Travaux Chimiques des Pays Bas 81(4):285–296

Dunky M (2003) Adhesives in the wood industry. In: Pizzi A, Mittal KL (eds) Handbook of adhesive technology, 2nd edn. Marcel Dekker Inc., New York, p 71. https://doi.org/10.1201/9780203912225.ch47

EN 314-1 (2004) Plywood–—bonding quality—part 1: test methods. European Committee for Standardization, Brussels

EN 314-2 (1993) Plywood—–bonding quality—part 2: requirements. European Committee for Standardization, Brussels

EN ISO 11402 (2005) Phenolic, amino and condensation resins—–determination of free-formaldehyde content. International Organization for Standardization, Geneva

EN ISO 12460-4 (2016) Wood based panels—determination of formaldehyde release—–part 4: desiccator method (ISO 12460-4:2016). European Committee for Standardization, Brussels

FAO (2018) Global production and trade of forest products in 2017. http://www.fao.org/forestry/statistics/80938/en/

Feng S, Cheng S, Yuan Z, Leitch M, Xu C (2013) Valorization of bark for chemicals and materials: a review. Renew Sustain Energy Rev 26:560–578. https://doi.org/10.1016/j.rser.2013.06.024

Frihart CR, Hunt CG (2010) Adhesives with wood materials, bond formation and performance. In: Wood Handbook—wood as an engineering material. General Technical Report FPL-GTR-190. Madison, WI: U.S. Department of Agriculture, Forest Service, Forest Products Laboratory, Ch. 10

Gangi M, Tabarsa T, Sepahvand S, Asghari J (2013) Reduction of formaldehyde emission from plywood. J Adhes Sci Technol 27:1407–1417. https://doi.org/10.1080/01694243.2012.739016

Gardner DJ, McGinnis GD (1988) Comparison of the reaction rates of the alkali–catalyzed addition of formaldehyde to phenol and selected lignins. J Wood Chem Technol 8(2):261–288

Garro Galvez JM, Fechtal M, Riedl B (1996) Gallic acid as a model of tannins in condensation with formaldehyde. Thermochim Acta 274:149–163. https://doi.org/10.1016/0040-6031(95)02630-4

Ghahri S, Mohebby B (2017) Soybean as adhesive for wood composites: applications and properties. Soybean—the basis of yield, bio-mass and productivity. InTech Publisher, London

Gui C, Zhu J, Zhang Z, Liu X (2016) Research progress on formaldehyde-free wood adhesive derived from soy flour. In: Rudawska A (ed) Adhesives—applications and properties . IntechOpen. https://doi.org/10.5772/65502

Gupta GK (2009) Development of bark-based environmental-friendly composite panels. Master’s thesis, Faculty of Forestry, University of Toronto, Canada

Harkin JM, Rowe JW (1971) Bark and its possible uses. Research Note FPL-091. U.S. Department of Agriculture, Forest Products Laboratory, Madison

Hodgson AT, Beal D, Mcilvaine JER (2002) Sources of formaldehyde, other aldehydes and terpenes in a new manufactured house. Indoor Air 12:235–242. https://doi.org/10.1034/j.1600-0668.2002.01129.x

IARC (2006) Formaldehyde, 2-butoxyethanol and 1-tert-butoxypropan-2-ol. In: Monographs on the Evaluation of carcinogenic risk to humans; world health organization–international agency for research on cancer: Lyon, France, 2006, vol 88, p 478

Jahanshaei S, Tabarsa T, Asghari J (2012) Eco-friendly tannin-phenol formaldehyde resin for producing wood composites. Pigm Resin Technol 41(5):296–301

Janiszewska D, Frackowiak I, Mytko K (2016) Exploitation of liquefied wood waste for binding recycled wood particleboards. Holzforschung 70(12):1135–1138. https://doi.org/10.1515/hf-2016-0043

Johns WE, Niazi KA (1980) Effect of pH and buffering capacity of wood on the gelation time of urea-formaldehyde resin. Wood Fiber Sci 12(4):255–263

Kamath YK, Hornby SB, Weigmann HD (1985) Irreversible chemisorption of formaldehyde on cotton cellulose. Textile Res J 55(11):663–666

Kim S (2009) Environment-friendly adhesives for surface bonding of wood-based flooring using natural tannin to reduce formaldehyde and TVOC emission. Bioresour Technol 100:744–748. https://doi.org/10.1016/j.biortech.2008.06.062

Łebkowska M, Załęska-Radziwiłł M, Tabernacka A (2017) Adhesives based on formaldehyde–—environmental problems. BioTechnologia 98(1):53–65

Malutan T, Nicu R, Popa VI (2008) Contribution to the study of hydroxymethylation reaction of alkali lignin. BioResources 3(1):13–20

Moubarik A, Allal A, Pizzi A, Charreir B, Carreir F (2010) Characterization of a formaldehyde-free cornstarch-tannin wood adhesive for interior plywood. Eur J Wood Prod 68:427–433. https://doi.org/10.1007/s00107-009-0379-0

Munoz F, Ballerini A, Gacitua W (2013) Variability of physical, morphological and thermal properties of Eucalyptus nitens bark filler. Maderas-Cienc Technol 15(1):17–30. https://doi.org/10.4067/S0718-221X2013005000002

Myers GE (1984) How mole ratio of UF resin affects formaldehyde emission and other properties: a literature critique. For Prod J 34:35–41

Myers GE (1986) Effects of post-manufacture board treatments on formaldehyde emission: a literature review (1960–1984). For Prod J 36:41–51

Nemli G, Colakoğlu G (2005) Effects of mimosa bark usage on some properties of particleboard. Turk J Agric For 29:227–230

Nemli G, Kirci H, Temiz A (2004) Influence of impregnating wood particles with mimosa bark extract on some properties of particleboard. Ind Crop Prod 20:339–344. https://doi.org/10.1016/j.indcrop.2003.11.006

Ong HR, Prasad DMR, Khan MR, Rao DS, Jeyaratnam N, Raman DK (2012) Effect of jatropha seed oil meal and rubber seed oil meal as melamine urea formaldehyde adhesive extender on the bonding strength of plywood. J Appl Sci 12:1148–1153. https://doi.org/10.3923/jas.2012.1148.1153

Ozgenc O, Durmaz S, Kustas S (2017) Chemical analysis of tree barks using ATR-FTIR spectroscopy and conventional techniques. BioResources 12(4):9143–9151. https://doi.org/10.15376/biores.12.4.9143-9151

Park BD, Kang EC, Park JY (2008) Thermal curing behavior of modified urea–formaldehyde resin adhesives with two formaldehyde scavengers and their influence on adhesion performance. J Appl Polym Sci 110(3):1573–1580. https://doi.org/10.1002/app.28748

Pasztory Z, Mohacsine IR, Gorbacheva G, Borcsok Z (2016) The utilization of tree bark. BioResources 11(3):7859–7888. https://doi.org/10.15376/biores.11.3.Pasztory

Pásztory Z, Ronyecz Mohácsiné I, Börcsök Z (2017) Investigation of thermal insulation panels made of black locust tree bark. Constr Build Mater 147:733–735. https://doi.org/10.1016/j.conbuildmat.2017.04.204

Pedieu R, Riedl B, Pichette A (2008) Properties of white birch (Betula papyrifera) outer bark particleboards with reinforcement of coarse wood particles in the core layer. Ann Forest Sci 65(701):1–9. https://doi.org/10.1051/forest:2008053

Pedieu R, Riedl B, Pichette A (2009) Properties of mixed particleboards based on white birch (Betula papyrifera) inner bark particles and reinforced with wood fibers. Eur J Wood Prod 67:95–101. https://doi.org/10.1007/s00107-008-0297-6

Pizzi A (1994) Advanced Wood Adhesives Technology. CRC Press: Boca Raton, FL, USA, 1994

Raquez J–M, Deléglise M, Lacrampe M–F, Krawczak P (2010) Thermosetting (bio)materials derived from renewable resources: a critical review. Prog Polym Sci 35(4):487–509. https://doi.org/10.1016/j.progpolymsci.2010.01.001

Réh R, Igaz R, Krišťák Ľ, Ružiak I, Gajtanska M, Božíková M, Kučerka M (2019) Functionality of beech bark in adhesive mixtures used in plywood and its effect on the stability associated with material systems. Materials 12:1298

Rhazi N, Oumam M, Sesbou A, Hannache H, Bouhtoury FC (2017) Physico-mechanical properties of plywood bonded with ecological adhesives from Acacia mollissima tannins and lignosulfonates. Eur Phys J Appl Phys 78:34813. https://doi.org/10.1051/epjap/2017170067

Roffael E (1982) Die Formaldehydabgabe von Spanplatten und anderen Werkstoffen [The release of formaldehyde from particleboards and other materials]. DRW, Stuttgart

Roffael E (2016) Significance of wood extractives for wood bonding. Appl Microbiol Biotechnol 100:1589–1596

Roffael E, Dix B, Okum J (2000) Use of spruce tannin as a binder in particleboards and medium density fiberboards (MDF). Holz Roh Werkst 58:301–305. https://doi.org/10.1007/s001070050432

Rowell RM (2005) Handbook of chemistry and wood composites. CRC Press, Boca Raton, 446 pp

Ružiak I, Igaz R, Krišťák L, Réh R, Mitterpach J, Očkajová A, Kučerka M (2017) Influence of urea-formaldehyde adhesive modification with beech bark on chosen properties of plywood. BioResources 12:3250–3264. https://doi.org/10.15376/biores.12.2.3250-3264

Sari B, Ayrilmis N, Nemli G, Baharoğlu M, Gümüşkaya E, Bardak S (2012) Effects of chemical composition of wood and resin type on properties of particleboard. Lignocellulose 1:174–184

Sastry GP (1969) The reaction of formaldehyde with spruce lignins. Holzforschung 23(1):15–17

Sedliačik J, Matyašovský J, Šmidriaková M, Sedliačiková M, Jurkovič P (2011) Application of collagen colloid from chrome shavings for innovative polycondensation adhesives. J Am Leather Chem As 106(11):332–340

Seifert VK (1956) Über ein neues Verfahren zur Schnellbestimmung der Rein—Cellulose (About a new method for rapid determination of pure cellulose). Das Papier 10(13/14):301–306

Sellers T, Miller GD, Smith W (2005) Tool wear properties of five extender/fillers in adhesive mixes for plywood. For Prod J 55(3):27–31

Sluiter A, Ruiz R, Scarlata C, Sluiter J, Templeton D (2008) Determination of extractives in biomass: laboratory analytical procedure (LAP). NREL/TP-510-42619. National Renewable Energy Laboratory, CO, Golden

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2008b) Determination of ash in biomass. Technical Report NREL/TP-510-42622. National Renewable Energy Laboratory Golden, CO

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2011) Determination of Structural carbohydrates and lignin in biomass: laboratory analytical procedure (LAP). NREL/TP-510-42618. National Renewable Energy Laboratory, CO, Golden

Takagaki A, Fukai K, Nanjo F, Hara Y (2000) Reactivity of green tea catechins with formaldehyde. J Wood Sci 46:334–338

Tanase C, Mocan A, Cosarca S, Gavan A, Nicolescu A, Gheldiu A-M, Vodnar DC, Muntean D-L, Crisan O (2019) Biological and chemical insights of Beech (Fagus sylvatica L.) bark: a source of bioactive compounds with functional properties. Antioxidants 8(9):E417. https://doi.org/10.3390/antiox8090417

Tudor EM, Barbu MC, Petutschnigg A, Réh R, Krišťák L (2020) Analysis of Larch-Bark capacity for formaldehyde removal in wood adhesives. Int J Environ Res Public Health 17:764. https://doi.org/10.3390/ijerph17030764

Umemura K, Ueda T, Munawar SS, Kawai S (2012) Application of citric acid as natural adhesive for wood. J Appl Polym Sci 123(4):1991–1996. https://doi.org/10.1002/app.34708

Vazquez G, Freire S, Rodriguez–Bona C, Gonzalez J, Antorrena G (1999) Structures, and reactivities with formaldehyde, of some acetosolv pine lignins. J Wood Chem Technol 19(4):357–378

Wise LE, Murphy M, D’addieco AA (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap Trade J 122(2):35–43

Yilgor N, Unsal O, Kartal SN (2001) Physical, mechanical, and chemical properties of steamed beech wood. Forest Prod J 51(11/12):89–93

Acknowledgements

The work was supported by the Slovak Academic Information Agency; and the Slovak Research and Development Agency under the contracts no. APVV-14-0506, APVV-16-0177, APVV-17-0583, APVV-18-0378; and ITMS project code: 313011T720 “LignoPro”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bekhta, P., Sedliačik, J., Noshchenko, G. et al. Characteristics of beech bark and its effect on properties of UF adhesive and on bonding strength and formaldehyde emission of plywood panels. Eur. J. Wood Prod. 79, 423–433 (2021). https://doi.org/10.1007/s00107-020-01632-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00107-020-01632-8