Abstract

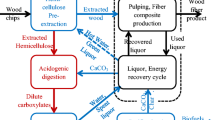

Polyhydroxyalkanoates (PHAs) are a group of biodegradable, compostable and biocompatible biopolymers that are synthesised by microorganisms. Intensive research efforts leading to significant developments on mixed culture PHA production over the years have led to commercialisation of these processes. However, potential feedstocks remain untapped due to technical and cost considerations that have limited the widespread use of this technology. This article is intended to review some wood processing industry residue conversion technologies for wood sugar and volatile fatty acid production. Wood sugars and volatile fatty acids can be carbon sources for mixed culture PHA production. A conceptual design incorporating wastewater treatment is proposed for PHA production, as a biorefinery option for an integrated wood processing site. The two-stage PHA production process utilises the carbon in wastewater produced in a pulp mill and sugars from pretreated wood residues to produce PHA reducing the cost of production and improving the carbon utilisation of wood processing sites. A mass balance-based model was used to evaluate scenarios with different PHA yields. The article also discusses some potential product options and market applications of PHA.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- AD:

-

Anaerobic digestion

- ADF:

-

Aerobic dynamic feeding

- ATP:

-

Adenosine triphosphate

- COD:

-

Chemical oxygen demand

- DO:

-

Dissolved oxygen

- DS:

-

Dissolved solids

- EPS:

-

Extracellular polymeric substance

- GAO:

-

Glycogen accumulating organisms

- HV:

-

Hydroxyvalerate

- LDPE:

-

Low-density polyethylene

- Mcl:

-

Medium-chain-length

- MMC:

-

Mixed microbial consortia

- Odt:

-

Oven-dry tonnes

- PAO:

-

Polyphosphate accumulating organisms

- PHA:

-

Polyhydroxyalkanoates

- PHB:

-

Polyhydroxybutyrate

- PHBV:

-

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate)

- PP:

-

Polypropylene

- PS:

-

Polystyrene

- RNA:

-

Ribonucleic acid

- SBR:

-

Sequencing batch reactor

- Scl:

-

Short-chain-length

- SCW:

-

Supercritical water

- ThOD:

-

Theoretical oxygen demand

- TMP:

-

Thermo-mechanical pulp

- TSS:

-

Total suspended solids

- VFA:

-

Volatile fatty acids

- WF:

-

Wood fibre

- WFRTC:

-

Wood fibre-reinforced thermoplastic composites

- WO:

-

Wet oxidation

- WPC:

-

Wood plastic composites

References

Albuquerque MGE, Eiroa M, Torres C, Nunes BR, Reis MAM (2007) Strategies for the development of a side stream process for polyhydroxyalkanoate (PHA) production from sugar cane molasses. J Biotechnol 130:411. https://doi.org/10.1016/j.jbiotec.2007.05.011

Albuquerque MGE, Concas S, Bengtsson S, Reis MAM (2010a) Mixed culture polyhydroxyalkanoates production from sugar molasses: the use of a 2-stage CSTR system for culture selection. Bioresour Technol 101:7112. https://doi.org/10.1016/j.biortech.2010.04.019

Albuquerque MGE, Torres CAV, Reis MAM (2010b) Polyhydroxyalkanoate (PHA) production by a mixed microbial culture using sugar molasses: effect of the influent substrate concentration on culture selection. Water Res 44:3419. https://doi.org/10.1016/j.watres.2010.03.021

Albuquerque MGE, Martino V, Pollet E, Avérous L, Reis MAM (2011) Mixed culture polyhydroxyalkanoate (PHA) production from volatile fatty acid (VFA)-rich streams: effect of substrate composition and feeding regime on PHA productivity, composition and properties. J Biotechnol 151:66. https://doi.org/10.1016/j.jbiotec.2010.10.070

Alexander N (2014) Production of chemicals from woody biomass by wet oxidation. Dissertation, Lappeenranta University of Technology, Finland. http://lutpub.lut.fi/bitstream/handle/10024/96409/

Andrews J, Smit AM, Wijeyekoon S, McDonald B, Baroutian S, Gapes D (2014) Application of hydrothermal treatment to affect the fermentability of Pinus radiata pulp mill effluent sludge. Bioresour Technol 170:100. https://doi.org/10.1016/j.biortech.2014.07.037

Andrews J, Dare P, Estcourt G, Gapes D, Lei R, McDonald B, Wijaya N (2015) Acetic acid recovery from a hybrid biological-hydrothermal treatment process of sewage sludge—a pilot plant study. Water Sci Technol 71:734. https://doi.org/10.2166/wst.2015.021

Anjali M, Sukumar C, Kanakalakshmi A, Shanthi K (2014) Enhancement of growth and production of polyhydroxyalkanoates by Bacillus subtilis from agro-industrial waste as carbon substrates. Compos Interfaces 21:111. https://doi.org/10.1080/15685543.2013.834200

Arato C, Pye EK, Gjennestad G (2005) The lignol approach to biorefining of woody biomass to produce ethanol and chemicals. Appl Biochem Biotechnol 123:0871. https://doi.org/10.1385/ABAB:123:1-3:0871

Baroutian S, Robinson M, Smit AM, Wijeyekoon S, Gapes D (2013) Transformation and removal of wood extractives from pulp mill sludge using wet oxidation and thermal hydrolysis. Bioresour Technol 146:294. https://doi.org/10.1016/j.biortech.2013.07.098

Baroutian S, Smit AM, Andrews J, Young B, Gapes D (2015) Hydrothermal degradation of organic matter in municipal sludge using non-catalytic wet oxidation. Chem Eng J 260:846. https://doi.org/10.1016/j.cej.2014.09.063

Baroutian S, Gapes DJ, Sarmah AK, Farid MM, Young BR (2016) Formation and degradation of valuable intermediate products during wet oxidation of municipal sludge. Bioresour Technol 205:280. https://doi.org/10.1016/j.biortech.2016.01.039

Bengtsson S, Werker A, Christensson M, Welander T (2008a) Production of polyhydroxyalkanoates by activated sludge treating a paper mill wastewater. Bioresour Technol 99:509. https://doi.org/10.1016/j.biortech.2007.01.020

Bengtsson S, Werker A, Welander T (2008b) Production of polyhydroxyalkanoates by glycogen accumulating organisms treating a paper mill wastewater. Water Sci Technol 58:323. https://doi.org/10.2166/wst.2008.381

Bengtsson S, Werker A, Visser C, Korving L (2017) Phario: stepping stone to a sustainable value chain for PHA bioplastic using municipal activated sludge. Stichting Toegepast Onderzoek Waterbeheer. https://www.stowa.nl/sites/default/files/assets/PUBLICATIES/Publicaties%202017/STOWA%202017-15.pdf. Accessed 21 Jun 2022

Bhaumik P, Dhepe PL (2015) Conversion of biomass into sugars. In: Murzin D, Simakova O (eds) Biomass sugars for non-fuel applications, Green chemistry series. RSC Publishing, Cambridge, pp 1–53. https://doi.org/10.1039/9781782622079-00001

Bhuwal AK, Singh G, Aggarwal NK, Goyal V, Yadav A (2013) Isolation and screening of polyhydroxyalkanoates producing bacteria from pulp, paper, and cardboard industry wastes. Int J Biomater 2013:1. https://doi.org/10.1155/2013/752821

Biomer Inc. (2019). http://www.biomer.de/IndexE.html. Accessed 20 Jan 2019

Bowers T, Vaidya A, Smith DA, Lloyd-Jones G (2014) Softwood hydrolysate as a carbon source for polyhydroxyalkanoate production. J Chem Technol Biotechnol 89:1030. https://doi.org/10.1002/jctb.4196

Cameron H, Campion SH, Singh T, Vaidya AA (2015) Improved saccharification of steam-exploded Pinus radiata on supplementing crude extract of Penicillium sp. 3 Biotech 5:221. https://doi.org/10.1007/s13205-014-0212-2

Chandra RP, Bura R, Mabee WE, Berlin A, Pan X, Saddler JN (2007) Substrate pretreatment: the key to effective enzymatic hydrolysis of lignocellulosics? In: Olsson L (ed) Biofuels, Advances in biochemical engineering/biotechnology, vol 108. Springer, Berlin, pp 67–93. https://doi.org/10.1007/10_2007_064

Chen GQ (2009) A microbial polyhydroxyalkanoates (PHA) based bio- and materials industry. Chem Soc Rev 38:2434. https://doi.org/10.1039/B812677C

Danimer Scientific (2019). https://danimerscientific.com/. Accessed 20 Jan 2019

Dias JML, Lemos PC, Serafim LS, Oliveira C, Eiroa M, Albuquerque MGE, Ramos AM, Oliveira R, Reis MAM (2006) Recent advances in polyhydroxyalkanoate production by mixed aerobic cultures: from the substrate to the final product. Macromol Biosci 6:885. https://doi.org/10.1002/mabi.200600112

Dionisi D, Carucci G, Papini MP, Riccardi C, Majone M, Carrasco F (2005) Olive oil mill effluents as a feedstock for production of biodegradable polymers. Water Res 39:2076. https://doi.org/10.1016/j.watres.2005.03.011

Dionisi D, Majone M, Vallini G, Di Gregorio S, Beccari M (2006) Effect of the applied organic load rate on biodegradable polymer production by mixed microbial cultures in a sequencing batch reactor. Biotechnol Bioeng 93:76. https://doi.org/10.1002/bit.20683

Duque A, Álvarez C, Doménech P, Manzanares P, Moreno AD (2021) Advanced bioethanol production: from novel raw materials to integrated biorefineries. Processes 9. https://doi.org/10.3390/pr9020206

Fortunebusinessinsights (2020) Advanced materials—wood plastic composite market. 2020 Fortune Business Insights. https://www.fortunebusinessinsights.com/wood-plastic-composite-market-102821. Accessed 27 Jun 2022

Galbe M, Zacchi G (2007) Pretreatment of lignocellulosic materials for efficient bioethanol production. In: Olsson L (ed) Biofuels, Advances in biochemical engineering/biotechnology, vol 108. Springer, Berlin, pp 41–65. https://doi.org/10.1007/10_2007_070

Gargulak JD, Lersch M (2012) Scaling up the BALI concept. In: Proceedings of the 12th international bioenergy bioproducts conference, Savannah

Haghighi Mood S, Hossein Golfeshan A, Tabatabaei M, Salehi Jouzani G, Najafi GH, Gholami M, Ardjmand M (2013) Lignocellulosic biomass to bioethanol, a comprehensive review with a focus on pretreatment. Renew Sustain Energy Rev 27:77. https://doi.org/10.1016/j.rser.2013.06.033

Huang F, Ragauskas AJ (2013) Chemical pretreatment techniques for biofuels and biorefineries from softwood. In: Fang Z (ed) Pretreatment techniques for biofuels and biorefineries, Green energy and technology. Springer, Berlin, pp 151–179. https://doi.org/10.1007/978-3-642-32735-3_8

Hubbe MA, Metts JR, Hermosilla D, Blanco MA, Yerushalmi L, Haghighat F, Lindholm-Lehto P, Khodaparast Z, Kamali M, Elliott A (2016) Wastewater treatment and reclamation: a review of pulp and paper industry practices and opportunities. BioResources 11(3):7953–8091

Humbird D, Davis L, Tao L, Kinchin C, Hsu D, Aden A, Schoen P, Lukas J, Olthof B, Worley M, Sexton D, Dudgeon D (2011) Process design and economics for biochemical conversion of lignocellulosic biomass to ethanol. National Renewable Energy Laboratory, Golden, CO. NREL/TP-5100-47764. https://www.nrel.gov/docs/fy11osti/47764.pdf. Accessed 15 Feb 2019

Jiang Y, Marang L, Kleerebezem R, Muyzer G, van Loosdrecht MCM (2011) Polyhydroxybutyrate production from lactate using a mixed microbial culture. Biotechnol Bioeng 108:2022. https://doi.org/10.1002/bit.23148

Jiang Y, Marang L, Tamis J, van Loosdrecht MCM, Dijkman H, Kleerebezem R (2012) Waste to resource: converting paper mill wastewater to bioplastic. Water Res 46:5517. https://doi.org/10.1016/j.watres.2012.07.028

Johnson K, Jiang Y, Kleerebezem R, Muyzer G, van Loosdrecht MCM (2009) Enrichment of a mixed bacterial culture with a high polyhydroxyalkanoate storage capacity. Biomacromolecules 10:670. https://doi.org/10.1021/bm8013796

Jung HR, Jeon JM, Yi DH, Song HS, Yang SY, Choi TR et al (2019) Poly (3-hydroxybutyrate-co-3-hydroxyvalerate-co-3-hydroxyhexanoate) terpolymer production from volatile fatty acids using engineered Ralstonia eutropha. Int J Biol Macromol 138:370. https://doi.org/10.1016/j.ijbiomac.2019.07.091

Kandhola G, Djioleu A, Carrier DJ, Kim JW (2017) Pretreatments for enhanced enzymatic hydrolysis of pinewood: a review. Bioenerg Res 10:1138. https://doi.org/10.1007/s12155-017-9862-3

Kibblewhite RP, Suckling ID, Evans R, Grace JC, Riddell M (2010) Lignin and carbohydrate variation with earlywood, latewood, and compression wood content of bent and straight ramets of a radiata pine clone. Holzforschung 64. https://doi.org/10.1515/hf.2010.016

Kim KH, Eom IY, Lee SM, Cho ST, Choi IG, Choi JW (2010) Applicability of sub- and supercritical water hydrolysis of woody biomass to produce monomeric sugars for cellulosic bioethanol fermentation. J Ind Eng Chem 16:918. https://doi.org/10.1016/j.jiec.2010.09.010

Koller M, Mukherjee A (2022) A new wave of industrialization of PHA biopolyesters. Bioengineering (Basel) 9. https://doi.org/10.3390/bioengineering9020074

Koller M, Maršálek L, de Sousa Dias MM, Braunegg G (2017) Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol 37:24. https://doi.org/10.1016/j.nbt.2016.05.001

Kong-Win Chang J, Duret X, Berberi V, Zahedi-Niaki H, Lavoie JM (2018) Two-step thermochemical cellulose hydrolysis with partial neutralization for glucose production. Front Chem 6. https://doi.org/10.3389/fchem.2018.00117

Kourmentza C, Placido J, Venetsaneas N, Burniol-Figols A, Varrone C, Gavala HN, Reis MAM (2017) Recent advances and challenges towards sustainable polyhydroxyalkanoate (PHA) production. Bioengineering 4. https://doi.org/10.3390/bioengineering4020055

Loge F (2005) Wastewater treatment generates PHA plastic. Ind Bioprocess 27(12):2

Luengo JM, García B, Sandoval A, Naharro G, Olivera ER (2003) Bioplastics from microorganisms. Curr Opin Microbiol 6:251. https://doi.org/10.1016/S1369-5274(03)00040-7

McAdam B, Brennan Fournet M, McDonald P, Mojicevic M (2020) Production of polyhydroxybutyrate (PHB) and factors impacting its chemical and mechanical characteristics. Polymers 12. https://doi.org/10.3390/polym12122908

McGrouther K, Wijeyekoon S, Lei R, Purchas C, Bridgman S (2013) Pulp and paper mill solid waste—closing the loop. In: WasteMINZ conference, Rotorua, New Zealand. https://www.wasteminz.org.nz/pubs/pulp-and-paper-mill-solid-waste-closing-the-loop/. Accessed 15 Jun 2022

Mehrpouya M, Vahabi H, Barletta M, Laheurte P, Langlois V (2021) Additive manufacturing of polyhydroxyalkanoates (PHAs) biopolymers: materials, printing techniques, and applications. Mater Sci Eng C Mater. https://doi.org/10.1016/j.msec.2021.112216

Merrill RA, Petersen K (2014) United States patent number US20140199740. http://www.google.com/patents/US20140199740. Accessed 15 Feb 2019

Morgan-Sagastume F, Karlsson A, Johansson P, Pratt S, Boon N, Lant P, Werker A (2010) Production of polyhydroxyalkanoates in open, mixed cultures from a waste sludge stream containing high levels of soluble organics, nitrogen and phosphorus. Water Res 44:5196. https://doi.org/10.1016/j.watres.2010.06.043

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673. https://doi.org/10.1016/j.biortech.2004.06.025

Możejko-Ciesielska J, Kiewisz R (2016) Bacterial polyhydroxyalkanoates: still fabulous? Microbiol Res 192:271. https://doi.org/10.1016/j.micres.2016.07.010

Newlight Technologies (2019). https://www.newlight.com/. Accessed 20 Jan 2019

Pozo G, Villamar AC, Martinez M, Vidal G (2011) Polyhydroxyalkanoates (PHA) biosynthesis from kraft mill wastewaters: biomass origin and C:N relationship influence. Water Sci Technol. https://doi.org/10.2166/wst.2011.242

Rabinovich ML (2010) Wood hydrolysis industry in the Soviet Union and Russia: a mini-review. Cellulose Chem Technol 44(4–6):173–186

Reis MAM, Serafim LS, Lemos PC, Ramos AM, Aguiar FR, van Loosdrecht MCM (2003) Production of polyhydroxyalkanoates by mixed microbial cultures. Bioprocess Biosyst Eng 25:377. https://doi.org/10.1007/s00449-003-0322-4

Renmatix (2019) Plantrose process. http://renmatix.com/process/how-we-do-it/plantrose-process. Accessed 20 Jan 2019

Rinaldi R, Schuth F (2009) Acid hydrolysis of cellulose as the entry point into biorefinery schemes. ChemSusChem 2:1096. https://doi.org/10.1002/cssc.200900188

Saka S, Ueno T (1999) Chemical conversion of various celluloses to glucose and its derivatives in supercritical water. Cellulose. https://doi.org/10.1023/A:1009232508644

Salehizadeh H, van Loosdrecht MCM (2004) Production of polyhydroxyalkanoates by mixed culture: recent trends and biotechnological importance. Biotechnol Adv 22:261. https://doi.org/10.1016/j.biotechadv.2003.09.003

Scott GM, Smith A (1995) Sludge characteristics and disposal alternatives for the pulp and paper industry. In: Proceedings of the 1995 international environmental conference, 1995 May 7–10, Atlanta, GA. TAPPI Press, Atlanta, GA, pp 269–279

Sekido H, Takezawa J, Motoki G, Akatsuka T (1990) Inhibitory effect of abietic acid against (Na+ +K+)- and (H++K+)-ATPases. Agric Biol Chem. https://doi.org/10.1080/00021369.1990.10869944

Silveira MHL, Morais ARC, Da Costa Lopes AM, Olekszyszen DN, Bogel-Łukasik R, Andreaus J, Pereira Ramos L (2015) Current pretreatment technologies for the development of cellulosic ethanol and biorefineries. ChemSusChem 8:3366. https://doi.org/10.1002/cssc.201500282

Suckling ID, Jack MW, Lloyd JA, Murton KD, Newman RH, Stuthridge TR, Torr KM, Vaidya AA (2017) A mild thermomechanical process for the enzymatic conversion of radiata pine into fermentable sugars and lignin. Biotechnol Biofuels 10:61. https://doi.org/10.1186/s13068-017-0748-6

Taherzadeh MJ, Karimi K (2007) Acid-based hydrolysis processes for ethanol from lignocellulosic materials: a review. Bioresources 2(3):472–499

TERAX® (2013) TERAX® 2013 Limited. https://www.scionresearch.com/about-us/about-scion/corporate-publications/scion-connections/past-issues-list/issue-19,-march-2016/ceo-for-terax-2013-ltd-goes-global. Accessed 20 Jan 2019

Thompson DN, Emerick RW, England AB, Flanders JP, Loge FJ, Wiedeman KA, Wolcott MP (2010) Development of renewable microbial polyesters for cost effective and energy-efficient wood-plastic composites. Idaho National Laboratory, Idaho Falls. http://www.osti.gov/scitech//servlets/purl/974527/. Accessed 25 Jan 2019

Uprichard JM (1991) Chemistry of wood and bark. In: Kininmonth JA, Whitehouse LJ (eds) Properties and uses of New Zealand Radiata pine, N.Z. Ministry of Forestry, Rotorua, pp 4–45

Vandi LJ, Chan CM, Werker A, Richardson D, Laycock B, Pratt S (2018) Wood-PHA composites: mapping opportunities. Polymers (Basel) 10. https://doi.org/10.3390/polym10070751

Venkateswar Reddy M, Venkata Mohan S (2012a) Effect of substrate load and nutrients concentration on the polyhydroxyalkanoates (PHA) production using mixed consortia through wastewater treatment. Bioresour Technol 114:573. https://doi.org/10.1016/j.biortech.2012.02.127

Venkateswar Reddy M, Venkata Mohan S (2012b) Influence of aerobic and anoxic microenvironments on polyhydroxyalkanoates (PHA) production from food waste and acidogenic effluents using aerobic consortia. Bioresour Technol 103:313. https://doi.org/10.1016/j.biortech.2011.09.040

Wijeyekoon SLJ, Vaidya AA (2021) Woody biomass as a potential feedstock for fermentative gaseous biofuel production. World J Microbiol Biotechnol 37:134. https://doi.org/10.1007/s11274-021-03102-6

Wijeyekoon S, Carere CR, West M, Nath S, Gapes D (2018) Mixed culture polyhydroxyalkanoate (PHA) synthesis from nutrient rich wet oxidation liquors. Water Res 140:1. https://doi.org/10.1016/j.watres.2018.04.017

Yan S, Tyagi RD, Surampalli RY (2006) Polyhydroxyalkanoates (PHA) production using wastewater as carbon source and activated sludge as microorganisms. Water Sci Technol 53:175. https://doi.org/10.2166/wst.2006.193

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Wijeyekoon, S.L.J., Suckling, I.D. (2023). Mixed Culture Polyhydroxyalkanoate Production as a Wood Processing Biorefinery Option. In: Pathak, P.D., Mandavgane, S.A. (eds) Biorefinery: A Sustainable Approach for the Production of Biomaterials, Biochemicals and Biofuels. Springer, Singapore. https://doi.org/10.1007/978-981-19-7481-6_1

Download citation

DOI: https://doi.org/10.1007/978-981-19-7481-6_1

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7480-9

Online ISBN: 978-981-19-7481-6

eBook Packages: Biomedical and Life SciencesBiomedical and Life Sciences (R0)