Abstract

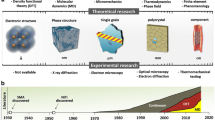

The shape-memory materials (SMMs) have a unique characteristic that they can remember their original shape prior to the deformation and return to their original shape after deformation on the application of the right stimulus such as heat, light, and chemical reaction. The shape-memory properties make these materials unique for structural applications, automobile, biomedical, aerospace, and actuators in micro-electromechanical systems (MEMSs). Few metallic alloy systems and most of the polymers exhibit shape-memory behavior, which can be programmed to achieve desired functionality in many of the applications. The temperature/strain-induced reversible martensitic phase transformation causes the shape-memory effects in the shape-memory alloys (SMAs). The transformation from hard to soft phase during the glass transition or melting attributes to the shape-memory behavior in shape-memory polymers (SMPs). The phase transformations causing the shape-memory effects are due to the atomic/molecular-level rearrangements of atoms/molecules, which are difficult and expensive to monitor through in situ experimental studies. In this scenario, molecular dynamics (MD) simulations provide significant insight into atomic-level details of the structural changes during loading or thermal treatment. It is evident that the MD simulations are a powerful tool for atomic-scale analysis of transformation and deformation characteristics of SMMs. This chapter provides a comprehensive review of the usage of MD simulations for a better and deeper understanding of the transformation and deformation behavior of SMMs.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Steinhauser MO, Hiermaier S (2009) A review of computational methods in materials science: examples from shock-wave and polymer physics. Int J Mol Sci 10:5135–5216. https://doi.org/10.3390/ijms10125135

Landman U (1988) Molecular dynamics simulations in material science and condensed matter physics BT—computer simulation studies in condensed matter physics. In: Landau DP, Mon KK, Schüttler H-B (eds) Springer. Berlin Heidelberg, Berlin, Heidelberg, pp 108–123

Kastner O (2012) First principles modelling of shape-memory alloys: molecular dynamics simulations, 1st edn. Springer, Berlin Heidelberg

Nakano A, Kalia RK, Vashishta P, Campbell TJ, Ogata S, Shimojo F, Saini S (2001) Scalable atomistic simulation algorithms for materials research. In: SC ’01: proceedings of the 2001 ACM/IEEE conference on supercomputing. p 10

LeSar R (2013) Introduction to computational materials science: fundamentals to applications. Cambridge University Press, Cambridge

Mohd Jani J, Leary M, Subic A, Gibson MA (2014) A review of shape-memory alloy research, applications and opportunities. Mater Des 56:1078–1113. https://doi.org/10.1016/j.matdes.2013.11.084

Lendlein A, Gould OEC (2019) Reprogrammable recovery and actuation behaviour of shape-memory polymers. Nat Rev Mater 4:116–133. https://doi.org/10.1038/s41578-018-0078-8

Allafi JK, Ren X, Eggeler G (2002) The mechanism of multistage martensitic transformations in aged Ni-rich NiTi shape-memory alloys. Acta Mater 50:793–803. https://doi.org/10.1016/S1359-6454(01)00385-8

Nishida M, Ohgi H, Itai I, Chiba A, Yamauchi K (1995) Electron microscopy studies of twin morphologies in B19′ martensite in the Ti–Ni shape-memory alloy. Acta Metall Mater 43:1219–1227. https://doi.org/10.1016/0956-7151(94)00332-C

Shaw JA, Kyriakides S (1995) Thermomechanical aspects of NiTi. J Mech Phys Solids 43:1243–1281. https://doi.org/10.1016/0022-5096(95)00024-D

Huang WM, Zhao Y, Wang CC, Ding Z, Purnawali H, Tang C, Zhang JL (2012) Thermo/chemo-responsive shape-memory effect in polymers: a sketch of working mechanisms, fundamentals and optimization. J Polym Res 19:9952. https://doi.org/10.1007/s10965-012-9952-z

Hatcher N, Yu OK, Freeman JA (2009) Structural stabilities, elastic constants, generalized stacking fault energetics, and the martensitic transformation mechanisms for the Ni50−xTiPtx (x = 0−30) ternary system: ab initio investigation. Eur Symp Martensitic Transform

Zarkevich NA, Johnson DD (2014) Shape-memory transformations of niti: minimum-energy pathways between austenite, martensites, and kinetically limited intermediate states. Phys Rev Lett 113:265701. https://doi.org/10.1103/PhysRevLett.113.265701

Kastner O (2003) Molecular-dynamics of a 2D model of the shape-memory effect. Contin Mech Thermodyn 15:487–502. https://doi.org/10.1007/s00161-003-0128-2

Kudoh Y, Tokonami M, Miyazaki S, Otsuka K (1985) Crystal structure of the martensite in Ti-49.2 at.%Ni alloy analyzed by the single crystal X-ray diffraction method. Acta Metall 33:2049–2056. https://doi.org/10.1016/0001-6160(85)90128-2

Pons J, Chernenko VA, Santamarta R, Cesari E (2000) Crystal structure of martensitic phases in Ni–Mn–Ga shape-memory alloys. Acta Mater 48:3027–3038. https://doi.org/10.1016/S1359-6454(00)00130-0

Sedmák P, Pilch J, Heller L, Kopeček J, Wright J, Sedlák P, Frost M, Šittner P (2016) Grain-resolved analysis of localized deformation in nickel-titanium wire under tensile load. Science (80- ) 353:559 LP–562. https://doi.org/10.1126/science.aad6700

Bhattacharya K, Conti S, Zanzotto G, Zimmer J (2004) Crystal symmetry and the reversibility of martensitic transformations. Nature 428:55–59. https://doi.org/10.1038/nature02378

Zhong Y, Gall K, Zhu T (2012) Atomistic characterization of pseudoelasticity and shape-memory in NiTi nanopillars. Acta Mater 60:6301–6311. https://doi.org/10.1016/j.actamat.2012.08.004

Mutter D, Nielaba P (2013) Simulation of the shape-memory effect in a NiTi nano model system. J Alloys Compd 577:S83–S87. https://doi.org/10.1016/j.jallcom.2012.01.095

Abberton BC, Liu WK, Keten S (2013) Coarse-grained simulation of molecular mechanisms of recovery in thermally activated shape-memory polymers. J Mech Phys Solids 61:2625–2637. https://doi.org/10.1016/j.jmps.2013.08.003

Amini M, Hasheminejad K, Montazeri A (2020) Experimentally guided MD simulation to enhance the shape-memory behavior of polymer-based nanocomposites: towards elaborating the underlying mechanism. Compos Part A Appl Sci Manuf 138:106055. https://doi.org/10.1016/j.compositesa.2020.106055

Sun L, Wang TX, Chen HM, Salvekar AV, Naveen BS, Xu Q, Weng Y, Guo X, Chen Y, Huang WM (2019) A brief review of the shape-memory phenomena in polymers and their typical sensor applications. Polymers (Basel) 11:1049. https://doi.org/10.3390/polym11061049

James RD, Zhang Z, James RD, Zhang Z (2005) A way to search for multiferroic materials with “Unlikely” combinations of physical properties BT—magnetism and structure in functional materials. In: Planes A, Mañosa L, Saxena A (eds) Springer. Berlin Heidelberg, Berlin, Heidelberg, pp 159–175

Huang X, Ackland GJ, Rabe KM (2003) Crystal structures and shape-memory behaviour of NiTi. Nat Mater 2:307–311. https://doi.org/10.1038/nmat884

François A, Veyssière P (1994) A TEM investigation of the deformation microstructure of CoZr and Co40Ni10Zr50 ordered alloys. Intermetallics 2:9–22. https://doi.org/10.1016/0966-9795(94)90046-9

Wang J, Sehitoglu H (2012) Resolving quandaries surrounding NiTi. Appl Phys Lett 101:81907. https://doi.org/10.1063/1.4747488

Farkas D, Roqueta D, Vilette A, Ternes K (1996) Atomistic simulations in ternary Ni–Ti–Al alloys. Model Simul Mater Sci Eng 4:359

Lai WS, Liu BX (2000) Lattice stability of some Ni-Ti alloy phases versus their chemical composition and disordering. J Phys Condens Matter 12:L53

Lai WS, Zhang Q, Liu BX, Ma E (2000) Structural stability and amorphization transition in the Ni–Ti system studied by molecular dynamics simulation with an n-body potential. J Phys Soc Jpn 69:2923–2937. https://doi.org/10.1143/JPSJ.69.2923

Sato T, Saitoh K, Shinke N (2006) Molecular dynamics study on microscopic mechanism for phase transformation of Ni–Ti alloy. Model Simul Mater Sci Eng 14:S39

Mutter D, Nielaba P (2011) Simulation of the thermally induced austenitic phase transition in NiTi nanoparticles. Eur Phys J B 84:109–113. https://doi.org/10.1140/epjb/e2011-20661-4

Mutter D, Nielaba P (2010) Simulation of structural phase transitions in NiTi. Phys Rev B 82:224201. https://doi.org/10.1103/PhysRevB.82.224201

Mirzaeifar R, Gall K, Zhu T, Yavari A, DesRoches R (2014) Structural transformations in NiTi shape-memory alloy nanowires. J Appl Phys 115:194307. https://doi.org/10.1063/1.4876715

Zhong Y, Gall K, Zhu T (2011) Atomistic study of nanotwins in NiTi shape-memory alloys. J Appl Phys 110:33532. https://doi.org/10.1063/1.3621429

Ko W-S, Grabowski B, Neugebauer J (2015) Development and application of a Ni–Ti interatomic potential with high predictive accuracy of the martensitic phase transition. Phys Rev B 92:134107. https://doi.org/10.1103/PhysRevB.92.134107

Chen Y, Molnárová O, Tyc O, Kadeřávek L, Heller L, Šittner P (2019) Recoverability of large strains and deformation twinning in martensite during tensile deformation of NiTi shape-memory alloy polycrystals. Acta Mater 180:243–259. https://doi.org/10.1016/j.actamat.2019.09.012

Breczko TM, Nelayev V, Dovzhik K, Najbuk M (2009) Computer simulations of the Ni2MnGa alloys. In: Proceedings of SPIE

Pun GPP, Yamakov V, Mishin Y (2015) Interatomic potential for the ternary Ni–Al–Co system and application to atomistic modeling of the B2–L10 martensitic transformation. Model Simul Mater Sci Eng 23:65006

Zhang XM, Fernandez J, Guilemany JM (2003) Origin of two way shape-memory effect in Cu-based shape-memory alloys. J de Physique IV (Proceedings). EDP sciences 487–493

Gui J, Cui Y, Xu S, Wang Q, Ye Y, Xiang M, Wang R (1994) Embedded-atom method study of the effect of the order degree on the lattice parameters of Cu-based shape-memory alloys. J Phys Condens Matter 6:4601

Ozgen S, Orhan O, Canbay CA, Brazolin GF, Silva RAG (2018) Investigation of grain formation mechanism in CuAl shape-memory alloy by molecular dynamic simulation. AIP Conf Proc 2042:20039. https://doi.org/10.1063/1.5078911

Entel P, Meyer R, Kadau K (2000) Molecular dynamics simulations of martensitic transitions. Philos Mag B 80:183–194. https://doi.org/10.1080/13642810008208607

Mayr SG, Arabi-Hashemi A (2012) Structural defects in Fe–Pd-based ferromagnetic shape-memory alloys: tuning transformation properties by ion irradiation and severe plastic deformation. New J Phys 14:103006

Zhang C, Hu J, Ji F, Fan Y, Liu Y (2012) A combined experimental and computational study on the material properties of shape-memory polyurethane. J Mol Model 18:1263–1271

Yang H, Wang Z, Guo Y, Shi X (2016) A molecular dynamics investigation of the deformation mechanism and shape-memory effect of epoxy shape memory polymers. Sci China Physics, Mech Astron 59:634601. https://doi.org/10.1007/s11433-015-5758-4

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Switzerland AG

About this chapter

Cite this chapter

Yedla, N., Salman, S.A., Karthik, V. (2022). Molecular Dynamics Simulations for Nanoscale Insight into the Phase Transformation and Deformation Behavior of Shape-Memory Materials. In: Maurya, M.R., Sadasivuni, K.K., Cabibihan, JJ., Ahmad, S., Kazim, S. (eds) Shape Memory Composites Based on Polymers and Metals for 4D Printing. Springer, Cham. https://doi.org/10.1007/978-3-030-94114-7_4

Download citation

DOI: https://doi.org/10.1007/978-3-030-94114-7_4

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-94113-0

Online ISBN: 978-3-030-94114-7

eBook Packages: EngineeringEngineering (R0)