Abstract

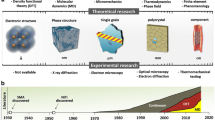

To unlock the lock of futuristic developments, nowadays shape memory alloys (SMAs) are acting as key by outnumbering the existing smart materials in view of new design competence, innovative techniques, enhanced technologies, and meeting the dire need according to the demand of ongoing scientific and industrial progress. Undoubtedly, it can be worthy to associate SMAs with the term polymorphism, as they possess unique capability to encapsulate multitudinous inherent characteristics under their name. Shape memory effect, superelasticity, and damping are there to name a few among many others, as prime indicators. The exhibition of these characteristics of SMAs is due to the transformation that takes place between austenite phase and martensite phase which is achieved either by temperature or stress variation. The fascinating characteristics they possess enable them to attract researchers and designers toward their potential applications in diverse domain as smart and multi-functional materials. The present work focuses on the review of research works accomplished in the recent 5 years pertaining to modeling and applications of shape memory alloys in distinct domains. Under the topic of modeling, a look into the research carried out on a variety of SMA structures—like functionally graded SMAs, SMA springs, porous SMAs, novel SMA actuators—is presented. In addition to this, the work carried out to represent SMAs with large strains and large rotations and to model polycrystalline SMAs is also covered. This is supplemented by application-oriented domains, each of which disseminates the attributes of SMAs that are self-sufficient to express what factors make SMAs more prominent. It is believed that the foregoing works comprehensively detailed in this review article will certainly lay a solid platform for the future investigations that are going to take place in time to come.

Similar content being viewed by others

References

Abdollahzadeh M, Hoseini SH, Faroughi S (2019) Modeling of superelastic behavior of porous shape memory alloys. Int J Mech Mater Des 2019:1–13

Abidi IH, Khalid FA, Farooq MU, Hussain MA, Maqbool A (2015) Tailoring the pore morphology of porous nitinol with suitable mechanical properties for biomedical applications. Mater Lett 154:17–20

Abouali S, Shahverdi M, Ghassemieh M, Motavalli M (2019) Nonlinear simulation of reinforced concrete beams retrofitted by near-surface mounted iron-based shape memory alloys. Eng Struct 187:133–148

Alam M, Youssef M, Nehdi M (2007) Utilizing shape memory alloys to enhance the performance and safety of civil infrastructure: a review. Can J Civ Eng 34(9):1075–1086

Alipour A, Kadkhodaei M, Ghaei A (2015) Finite element simulation of shape memory alloy wires using a user material subroutine: parametric study on heating rate, conductivity, and heat convection. J Intell Mater Syst Struct 26(5):554–572

Alvandi S, Ghassemieh M (2014) Application of shape memory alloys in seismic isolation: a review. Civ Eng Infrastruct J 47(2):153–171

Ameduri S, Favaloro N, Pellone L et al (2016) A shape memory alloy application for compact unmanned aerial vehicles. Aerospace 3(2):16

Ancker C (1958) Pitch and curvature corrections for helical springs. J Appl Mech 25:466–470

Auricchio F, Petrini L (2004) A three-dimensional model describing stress-temperature induced solid phase transformations: solution algorithm and boundary value problems. Int J Numer Methods Eng 61(6):807–836

Aversa R, Tamburrino F, Petrescu RV, Petrescu FI, Artur M, Chen G, Apicella A (2016) Biomechanically inspired shape memory effect machines driven by muscle like acting NiTi alloys. Am J Appl Sci 13(11):1264–1271

Barbarino S, Flores ES, Ajaj RM, Dayyani I, Friswell MI (2014) A review on shape memory alloys with applications to morphing aircraft. Smart Mater Struct 23(6):063001

Birman V (1997) Review of mechanics of shape memory alloy structures. Appl Mech Rev 50(11):629–645

Bonilla L, Hassan MM, Noorvand H, Rupnow T, Okeil A (2017) Dual self-healing mechanisms with microcapsules and shape memory alloys in reinforced concrete. J Mater Civ Eng 30(2):04017277

Boyd JG, Lagoudas DC (1996) A thermodynamical constitutive model for shape memory materials. Part I. The monolithic shape memory alloy. Int J Plast 12(6):805–842

Cai W, Meng X, Zhao L (2005) Recent development of tini-based shape memory alloys. Curr Opin Solid State Mater Sci 9(6):296–302

Chang W-S, Araki Y (2016) Use of shape-memory alloys in construction: a critical review. Proc Inst Civ Eng Civ Eng 169(2):87–95

Chemisky Y, Duval A, Patoor E, Zineb TB (2011) Constitutive model for shape memory alloys including phase transformation, martensitic reorientation and twins accommodation. Mech Mater 43(7):361–376

Cisse C, Zaki W, Zineb TB (2016a) A review of constitutive models and modeling techniques for shape memory alloys. Int J Plast 76:244–284

Cisse C, Zaki W, Zineb TB (2016b) A review of modeling techniques for advanced effects in shape memory alloy behavior. Smart Mater Struct 25(10):103001

Cladera A, Weber B, Leinenbach C, Czaderski C, Shahverdi M, Motavalli M (2014) Iron-based shape memory alloys for civil engineering structures: an overview. Constr Build Mater 63:281–293

Cortez-Vega R, Chairez I, Luviano-Juárez A, Feliu-Batlle V (2018) A hybrid dynamic model of shape memory alloy spring actuators. Measurement 114:340–353

Dadbakhsh S, Speirs M, Van Humbeeck J, Kruth J-P (2016) Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: from processes to potential biomedical applications. MRS Bull 41(10):765–774

Daghash SM, Ozbulut OE (2016) Characterization of superelastic shape memory alloy fiber-reinforced polymer composites under tensile cyclic loading. Mater Des 111:504–512

Daghash SM, Ozbulut OE (2017) Bond-slip behavior of superelastic shape memory alloys for near-surface-mounted strengthening applications. Smart Mater Struct 26(3):035020

Das S, Sajeer M, Chakraborty A (2019) Vibration control of horizontal axis offshore wind turbine blade using SMA stiffener. Smart Mater Struct 28:095025

Dehaghani PF, Ardakani SH, Bayesteh H, Mohammadi S (2017) 3D hierarchical multiscale analysis of heterogeneous sma based materials. Int J Solids Struct 118:24–40

DesRoches R, Smith B (2004) Shape memory alloys in seismic resistant design and retrofit: a critical review of their potential and limitations. J Earthq Eng 8(3):415–429

DİLİBAL (2016) The effect of long-term heat treatment on the thermomechanical behavior of NiTi shape memory alloys in defense and aerospace applications. J Def Sci/Savunma Bilmleri Dergisi 15(2):1–23

Duerig TW, Melton K, Stöckel D (2013) Engineering aspects of shape memory alloys. Butterworth-Heinemann, Oxford

Enferadi MH, Ghasemi MR, Shabakhty N (2019) Wave-induced vibration control of offshore jacket platforms through SMA dampers. Appl Ocean Res 90:101848

Eulert DD (1969) Symposium on rolamite. Technology Application Center, Institute for Social Research and Development, The University of New Mexico, and Office of Industrial Cooperation, Sandia Laboratories

Evangelista V, Marfia S, Sacco E (2009) Phenomenological 3D and 1D consistent models for shape-memory alloy materials. Comput Mech 44(3):405

Exarchos D, Dalla P, Tragazikis I, Dassios K, Zafeiropoulos N, Karabela M, De Crescenzo C, Karatza D, Musmarra D, Chianese S et al (2018) Development and characterization of high performance shape memory alloy coatings for structural aerospace applications. Materials 11(5):832

Fang C, Zhou X, Osofero AI, Shu Z, Corradi M (2016) Superelastic sma belleville washers for seismic resisting applications: experimental study and modelling strategy. Smart Mater Struct 25(10):105013

Ghafoori E, Neuenschwander M, Shahverdi M, Czaderski C, Fontana M (2019) Elevated temperature behavior of an iron-based shape memory alloy used for prestressed strengthening of civil structures. Constr Build Mater 211:437–452

Ghasemi MR, Shabakhty N, Enferadi MH (2019) Optimized SMA dampers in vibration control of jacket-type offshore structures (regular waves). Int J Coast Offshore Eng 2(4):25–35

Ghassemieh M, Rezapour M, Sadeghi V (2017) Effectiveness of the shape memory alloy reinforcement in concrete coupled shear walls. J Intell Mater Syst Struct 28(5):640–652

Gu X, Zhang W, Zaki W, Moumni Z (2017) Numerical simulation of pseudoelastic shape memory alloys using the large time increment method. Smart Mater Struct 26(4):045016

Haghdoust P, Lo Conte A, Cinquemani S, Lecis N (2018) A numerical method to model non-linear damping behaviour of martensitic shape memory alloys. Materials 11(11):2178

Hargovind S, Narendranath S, Ramesh MR (2019) Advanced machining of TiNiCo shape memory alloys for biomedical applications. Emerg Mater Res 8(1):14–21

Hartl D, Mabe J, Benafan O, Coda A, Conduit B, Padan R, Van Doren B (2015) Standardization of shape memory alloy test methods toward certification of aerospace applications. Smart Mater Struct 24(8):082001

Hashemi YM, Kadkhodaei M, Salehan M (2019) Fully coupled thermomechanical modeling of shape memory alloys under multiaxial loadings and implementation by finite element method. Continuum Mech Thermodyn 31(6):1683–1698

Hassan M, Mehrpouya M, Emamian S, Sheikholeslam M (2013) Review of self-healing effect on shape memory alloy (SMA) structures. Adv Mater Res 701:87–92

Heidari B, Kadkhodaei M, Barati M, Karimzadeh F (2016) Fabrication and modeling of shape memory alloy springs. Smart Mater Struct 25(12):125003

Heintze O et al (2004) A computationally efficient free energy model for shape memory alloys-experiments and theory. North Carolina State University, Raleigh

Huang H, Chang W-S (2018) Application of pre-stressed sma-based tuned mass damper to a timber floor system. Eng Struct 167:143–150

Hübler M, Nissle S, Gurka M, Breuer U (2016) Fiber-reinforced polymers with integrated shape memory alloy actuation: an innovative actuation method for aerodynamic applications. CEAS Aeronaut J 7(4):567–576

Ibrahim MK, Hamzah E, Nazim E, Bahador A et al (2018a) Parameter optimization of microwave sintering porous Ti–23% Nb shape memory alloys for biomedical applications. Trans Nonferrous Met Soc China 28(4):700–710

Ibrahim MK, Hamzah E, Saud SN, Nazim E (2018b) Powder metallurgy fabrication of porous 51 (at.%) Ni–Ti shape memory alloys for biomedical applications. Shape Mem Superelast 4(2):327–336

Izadi M, Ghafoori E, Shahverdi M, Motavalli M, Maalek S (2018) Development of an iron-based shape memory alloy (Fe-SMA) strengthening system for steel plates. Eng Struct 174:433–446

Izadi M, Motavalli M, Ghafoori E (2019) Iron-based shape memory alloy (Fe-SMA) for fatigue strengthening of cracked steel bridge connections. Constr Build Mater 227:116800

Jafarzadeh S, Kadkhodaei M (2017) Finite element simulation of ferromagnetic shape memory alloys using a revised constitutive model. J Intell Mater Syst Struct 28(19):2853–2871

Jani JM, Leary M, Subic A, Gibson MA (2014) A review of shape memory alloy research, applications and opportunities. Mater Des (1980–2015) 56:1078–1113

Kandasamy R, Cui F, Townsend N, Foo CC, Guo J, Shenoi A, Xiong Y (2016) A review of vibration control methods for marine offshore structures. Ocean Eng 127:279–297

Kapoor D (2017) Nitinol for medical applications: a brief introduction to the properties and processing of nickel titanium shape memory alloys and their use in stents. Johns Matthey Technol Rev 61(1):66–76

Kapuria S, Das H (2018) Improving hydrodynamic efficiency of composite marine propellers in off-design conditions using shape memory alloy composite actuators. Ocean Eng 168:185–203

Karagiannis D, Stamatelos D, Kappatos V, Spathopoulos T (2017) An investigation of shape memory alloys as actuating elements in aerospace morphing applications. Mech Adv Mater Struct 24(8):647–657

Karamooz-Ravari M, Shahriari B (2018) A numerical model based on voronoi tessellation for the simulation of the mechanical response of porous shape memory alloys. Meccanica 53(13):3383–3397

Khalili V, Khalil-Allafi J, Sengstock C, Motemani Y, Paulsen A, Frenzel J, Eggeler G, Köller M (2016) Characterization of mechanical properties of hydroxyapatite-silicon-multi walled carbon nano tubes composite coatings synthesized by epd on NiTi alloys for biomedical application. J Mech Behav Biomed Mater 59:337–352

Khandelwal A, Buravalla V (2009) Models for shape memory alloy behavior: an overview of modeling approaches. Int J Struct Changes Solids 1(1):111–148

Kim MK, Kim DJ, Chung Y-S, Choi E (2016) Direct tensile behavior of shape-memory-alloy fiber-reinforced cement composites. Constr Build Mater 102:462–470

Kök M, Ateş G (2017) The effect of addition of various elements on properties of NiTi-based shape memory alloys for biomedical application. Eur Phys J Plus 132(4):185

Konh B, Honarvar M, Hutapea P (2015) Design optimization study of a shape memory alloy active needle for biomedical applications. Med Eng Phys 37(5):469–477

Konopatsky A, Dubinskiy S, Zhukova YS, Sheremetyev V, Brailovski V, Prokoshkin S, Filonov M (2017) Ternary Ti–Zr–Nb and quaternary Ti–Zr–Nb–Ta shape memory alloys for biomedical applications: structural features and cyclic mechanical properties. Mater Sci Eng A 702:301–311

Kramer SL et al (1996) Geotechnical earthquake engineering. Pearson Education India, New Delhi

Lagoudas DC (2008) Shape memory alloys: modeling and engineering applications. Springer, Berlin

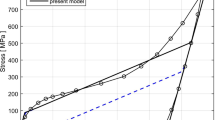

Lagoudas D, Hartl D, Chemisky Y, Machado L, Popov P (2012) Constitutive model for the numerical analysis of phase transformation in polycrystalline shape memory alloys. Int J Plast 32:155–183

Lai M, Gao Y, Yuan B, Zhu M (2015) Effect of pore structure regulation on the properties of porous TiNbZr shape memory alloys for biomedical application. J Mater Eng Perform 24(1):136–142

Lambert TR, Gurley A, Beale D (2017) Sma actuator material model with self-sensing and sliding-mode control: experiment and multibody dynamics model. Smart Mater Struct 26(3):035004

Leal PB, Savi MA (2018) Shape memory alloy-based mechanism for aeronautical application: theory, optimization and experiment. Aerosp Sci Technol 76:155–163

Leal PB, Savi MA, Hartl DJ (2018) Aero-structural optimization of shape memory alloy-based wing morphing via a class/shape transformation approach. Proc Instit Mech Eng Part G J Aerosp Eng 232(15):2745–2759

Lecce L et al (2014) Shape memory alloy engineering: for aerospace, structural and biomedical applications. Elsevier, Berlin

Li H, Qiu K, Zhou F, Li L, Zheng Y (2016) Design and development of novel antibacterial Ti–Ni–Cu shape memory alloys for biomedical application. Sci Rep 6:37475

Liu B, Hu S, Zhang W, Zhou R, Zhang Y, Zhu Y (2017) A theoretical model for functionally graded shape memory alloy cylinders subjected to internal pressure. J Mater Res 32(7):1397–1406

Liu X, Li J, Tsang H-H, Wilson J (2018) Enhancing seismic performance of unbonded prestressed concrete bridge column using superelastic shape memory alloy. J Intell Mater Syst Struct 29(15):3082–3096

Lobo PS, Almeida J, Guerreiro L (2015) Shape memory alloys behaviour: a review. Proc Eng 114:776–783

Mas B, Biggs D, Vieito I, Cladera A, Shaw J, Martínez-Abella F (2017) Superelastic shape memory alloy cables for reinforced concrete applications. Constr Build Mater 148:307–320

Masing G (1926) Eigenspannungen und verfestigung beim messing (fundamental stresses and strengthening with brass). In: Proceedings of the 2nd international congress of applied mechanics, pp 12–17

Matsuzaki Y, Naito H (2004) Macroscopic and microscopic constitutive models of shape memory alloys based on phase interaction energy function: a review. J Intell Mater Syst Struct 15(2):141–155

Miyazaki S, Otsuka K (1989) Development of shape memory alloys. ISIJ Int 29(5):353–377

Miyazaki S, Fu YQ, Huang WM (2009) Thin film shape memory alloys: fundamentals and device applications. Cambridge University Press, Cambridge

Naresh C, Bose P, Rao C (2016) Shape memory alloys: a state of art review. IOP Conf Ser Mater Sci Eng 149(1):012054

Nematollahi M, Baghbaderani KS, Amerinatanzi A, Zamanian H, Elahinia M (2019) Application of NiTi in assistive and rehabilitation devices: a review. Bioengineering 6(2):37

Ng C, Chan C, Man H, Waugh D, Lawrence J (2017) NiTi shape memory alloy with enhanced wear performance by laser selective area nitriding for orthopaedic applications. Surf Coat Technol 309:1015–1022

NourEldin M, Naeem A, Kim J (2019) Life-cycle cost evaluation of steel structures retrofitted with steel slit damper and shape memory alloy-based hybrid damper. Adv Struct Eng 22(1):3–16

Otsuka K, Ren X (1999) Recent developments in the research of shape memory alloys. Intermetallics 7(5):511–528

Otsuka K, Wayman CM (1999) Shape memory materials. Cambridge University Press, Cambridge

Ozbulut O, Hurlebaus S, Desroches R (2011) Seismic response control using shape memory alloys: a review. J Intell Mater Syst Struct 22(14):1531–1549

Paiva A, Savi MA (2006) An overview of constitutive models for shape memory alloys. Math Probl Eng 2006:56876

Patil D, Song G (2017) A review of shape memory material’s applications in the offshore oil and gas industry. Smart Mater Struct 26(9):093002

Peng H, Chen J, Wang Y, Wen Y (2018) Key factors achieving large recovery strains in polycrystalline Fe–Mn–Si-based shape memory alloys: a review. Adv Eng Mater 20(3):1700741

Pequegnat A, Michael A, Wang J, Lian K, Zhou Y, Khan M (2015) Surface characterizations of laser modified biomedical grade NiTi shape memory alloys. Mater Sci Eng C 50:367–378

Petrini L, Migliavacca F (2011) Biomedical applications of shape memory alloys. J Metall 2011:15

Pittaccio S, Garavaglia L, Ceriotti C, Passaretti F (2015) Applications of shape memory alloys for neurology and neuromuscular rehabilitation. J Funct Biomater 6(2):328–344

Prokoshkin S, Brailovski V, Dubinskiy S, Zhukova Y, Sheremetyev V, Konopatsky A, Inaekyan K (2016) Manufacturing, structure control, and functional testing of Ti–Nb-based SMA for medical application. Shape Mem Superelast 2(2):130–144

Qian H, Li H, Song G, Chen H, Ren W, Zhang S (2010) Seismic vibration control of civil structures using shape memory alloys: a review. In: Earth and space 2010: engineering, science, construction, and operations in challenging environments, pp 3377–3395

Qiao L, Rimoli JJ, Chen Y, Schuh CA, Radovitzky R (2011) Nonlocal superelastic model of size-dependent hardening and dissipation in single crystal Cu–Al–Ni shape memory alloys. Phys Rev Lett 106(8):085504

Quan D, Hai X (2015) Shape memory alloy in various aviation field. Proc Eng 99:1241–1246

Rad ZR, Ghobadi MS, Yakhchalian M (2019) Probabilistic seismic collapse and residual drift assessment of smart buildings equipped with shape memory alloy connections. Eng Struct 197:109375

Rao A, Srinivasa AR, Reddy JN (2015) Design of shape memory alloy (SMA) actuators, vol 3. Springer, Berlin

Rius JM, Cladera A, Ribas C, Mas B (2019) Shear strengthening of reinforced concrete beams using shape memory alloys. Constr Build Mater 200:420–435

Rizzello G, Mandolino MA, Schmidt M, Naso D, Seelecke S (2018) An accurate dynamic model for polycrystalline shape memory alloy wire actuators and sensors. Smart Mater Struct 28:025020

Rojob H, El-Hacha R (2017) Self-prestressing using iron-based shape memory alloy for flexural strengthening of reinforced concrete beams. ACI Struct J 114(2):523

Santos FAd, Nunes J (2018) Toward an adaptive vibration absorber using shape-memory alloys, for civil engineering applications. J Intell Mater Syst Struct 29(5):729–740

Saygili HH, Tugrul HO, Kockar B (2019) Effect of aging heat treatment on the high cycle fatigue life of Ni 50.3 Ti 29.7 Hf 20 high-temperature shape memory alloy. Shape Mem Superelast 5(1):32–41

Scalet G, Boatti E, Ferraro M, Mercuri V, Hartl DJ, Auricchio F (2017) Explicit finite element implementation of a shape memory alloy constitutive model and associated analyses. In: Proceedings of XIV international conference on computational plasticity-COMPLAS

Sepe V, Marfia S, Sacco E (2013) A nonuniform tfa homogenization technique based on piecewise interpolation functions of the inelastic field. Int J Solids Struct 50(5):725–742

Sepe V, Auricchio F, Marfia S, Sacco E (2016) Homogenization techniques for the analysis of porous sma. Comput Mech 57(5):755–772

Shahverdi M, Czaderski C, Motavalli M (2016) Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams. Constr Build Mater 112:28–38

Shahverdi M, Michels J, Czaderski C, Motavalli M (2018) Iron-based shape memory alloy strips for strengthening rc members: material behavior and characterization. Constr Build Mater 173:586–599

Shajil N, Srinivasan S, Santhanam M (2016) An experimental study on self-centering and ductility of pseudo-elastic shape memory alloy (PESMA) fiber reinforced beam and beam-column joint specimens. Mater Struct 49(3):783–793

Sheremetyev V, Brailovski V, Prokoshkin S, Inaekyan K, Dubinskiy S (2016) Functional fatigue behavior of superelastic beta Ti–22Nb–6Zr (at%) alloy for load-bearing biomedical applications. Mater Sci Eng C 58:935–944

Sheremetyev V, Kudryashova A, Dubinskiy S, Galkin S, Prokoshkin S, Brailovski V (2018) Structure and functional properties of metastable beta Ti–18Zr–14Nb (at%) alloy for biomedical applications subjected to radial shear rolling and thermomechanical treatment. J Alloy Compd 737:678–683

Shirani M, Kadkhodaei M (2014) A geometrical approach to determine reorientation start and continuation conditions in ferromagnetic shape memory alloys considering the effects of loading history. Smart Mater Struct 23(12):125008

Shirani M, Kadkhodaei M (2015) A modified constitutive model with an enhanced phase diagram for ferromagnetic shape memory alloys. J Intell Mater Syst Struct 26(1):56–68

Song G, Ma N, Li H-N (2006) Applications of shape memory alloys in civil structures. Eng Struct 28(9):1266–1274

Song G, Patil D, Kocurek C, Bartos J (2010) Applications of shape memory alloys in offshore oil and gas industry: a review. In: Earth and space 2010: engineering, science, construction, and operations in challenging environments, pp 1551–1567

Sousa VCd, De Marqui Junior C, Elahinia MH (2018) Effect of constitutive model parameters on the aeroelastic behavior of an airfoil with shape memory alloy springs. J Vib Control 24(6):1065–1085

Souza AC, Mamiya EN, Zouain N (1998) Three-dimensional model for solids undergoing stress-induced phase transformations. Eur J Mech A/Solids 17(5):789–806

Spaggiari A, Dragoni E (2014) Analytical and numerical modeling of shape memory alloy negator springs for constant-force, long-stroke actuators. J Intell Mater Syst Struct 25(9):1139–1148

Spaggiari A, Dragoni E (2017) Analytical modelling of rolamite mechanism made of shape-memory alloy for constant force actuators. J Intell Mater Syst Struct 28(16):2208–2221

Spaggiari A, Dragoni E, Tuissi A (2015) Experimental characterization and modelling validation of shape memory alloy negator springs. J Intell Mater Syst Struct 26(6):619–630

Sun B, Meng X, Gao Z, Cai W (2018) Martensite structure and mechanical property of Ti–Nb–Ag shape memory alloys for biomedical applications. Vacuum 156:181–186

Urbano MF, Cadelli A, Sczerzenie F, Luccarelli P, Beretta S, Coda A (2015) Inclusions size-based fatigue life prediction model of NiTi alloy for biomedical applications. Shape Mem Superelast 1(2):240–251

Van Humbeeck J (2001) Shape memory alloys: a material and a technology. Adv Eng Mater 3(11):837–850

Van Humbeeck J, Chandrasekaran M, Delaey L (1991) Shape memory alloys: materials in action. Endeavour 15(4):148–154

Van Viet N, Zaki W, Umer R (2018) Analytical model for a superelastic timoshenko shape memory alloy beam subjected to a loading–unloading cycle. J Intell Mater Syst Struct 29(20):3902–3922

Viet N, Zaki W, Umer R (2018) Analytical model of functionally graded material/shape memory alloy composite cantilever beam under bending. Compos Struct 203:764–776

Wang Q, Wu N (2011) A review on structural enhancement and repair using piezoelectric materials and shape memory alloys. Smart Mater Struct 21(1):013001

Wang J, Moumni Z, Zhang W (2017) A thermomechanically coupled finite-strain constitutive model for cyclic pseudoelasticity of polycrystalline shape memory alloys. Int J Plast 97:194–221

Wang J, Zhang W, Zhu J, Xu Y, Gu X, Moumni Z (2019a) Finite element simulation of thermomechanical training on functional stability of shape memory alloy wave spring actuator. J Intell Mater Syst Struct 30(8):1239–1251

Wang B, Zhu S, Zhao J, Jiang H (2019b) Earthquake resilient RC walls using shape memory alloy bars and replaceable energy dissipating devices. Smart Mater Struct 28(6):065021

Weirich A, Kuhlenkötter B (2019) Applicability of shape memory alloys in aircraft interiors. Actuators 8(3):61

Wilson JC, Wesolowsky MJ (2005) Shape memory alloys for seismic response modification: a state-of-the-art review. Earthq Spectra 21(2):569–601

Witkowska J, Sowińska A, Czarnowska E, Płociński T, Borowski T, Wierzchoń T (2017) Niti shape-memory alloy oxidized in low-temperature plasma with carbon coating: characteristic and a potential for cardiovascular applications. Appl Surf Sci 421:89–96

Wu S, Lin H (2000) Recent development of tini-based shape memory alloys in taiwan. Mater Chem Phys 64(2):81–92

Xu R, Bouby C, Zahrouni H, Zineb TB, Hu H, Potier-Ferry M (2018) 3D modeling of shape memory alloy fiber reinforced composites by multiscale finite element method. Compos Struct 200:408–419

Xu L, Baxevanis T, Lagoudas DC (2019) A three-dimensional constitutive model for the martensitic transformation in polycrystalline shape memory alloys under large deformation. Smart Mater Struct 28(7):074004

Yamauchi K, Ohkata I, Tsuchiya K, Miyazaki S (2011) Shape memory and superelastic alloys: applications and technologies. Elsevier, Berlin

Yoneyama T, Miyazaki S (2008) Shape memory alloys for biomedical applications. Elsevier, Berlin

Yu C, Kang G, Kan Q (2018) An equivalent local constitutive model for grain size dependent deformation of NiTi polycrystalline shape memory alloys. Int J Mech Sci 138:34–41

Yuan B, Zhu M, Chung C (2018) Biomedical porous shape memory alloys for hard-tissue replacement materials. Materials 11(9):1716

Zainal M, Sahlan S, Ali M (2015) Micromachined shape-memory-alloy microactuators and their application in biomedical devices. Micromachines 6(7):879–901

Zaki W, Moumni Z (2007) A three-dimensional model of the thermomechanical behavior of shape memory alloys. J Mech Phys Solids 55(11):2455–2490

Zaki W, Viet N (2018) Analytical model of shape memory alloy helical springs. In: ASME 2018 conference on smart materials, adaptive structures and intelligent systems. American Society of Mechanical Engineers Digital Collection

Zareie S, Alam MS, Seethaler RJ, Zabihollah A (2019) Effect of shape memory alloy-magnetorheological fluid-based structural control system on the marine structure using nonlinear time-history analysis. Appl Ocean Res 91:101836

Zhang B-L, Han Q-L, Zhang X-M (2017a) Recent advances in vibration control of offshore platforms. Nonlinear Dyn 89(2):755–771

Zhang J, Ma Z, Liu F, Zhang C, Sharafi P, Rashidi M (2017b) Seismic performance and ice-induced vibration control of offshore platform structures based on the ISO-PFD-SMA brace system. Adv Mater Sci Eng 2017:15

Zhao Y, Taya M, Kang Y, Kawasaki A (2005) Compression behavior of porous NiTi shape memory alloy. Acta Mater 53(2):337–343

Zhou D, Gao Y, Lai M, Li H, Yuan B, Zhu M (2015) Fabrication of NiTi shape memory alloys with graded porosity to imitate human long-bone structure. J Bionic Eng 12(4):575–582

Acknowledgements

The authors convey their sincere thanks to the National Institute for Research and Development in Defence Shipbuilding-New Delhi (NIRDESH) and the Office of Naval Research-Global (ONRG) for supporting this work. The authors also gratefully acknowledge the University Grants Commission (UGC), New Delhi for providing Dr. D.S. Kothari Postdoctoral Fellowship to S. Kumar (through award letter No. F.4-2/2006 (BSR)/MA/17-18/0016).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Shivashankar, P. & Gopalakrishnan, S. A half a decade timeline of shape memory alloys in modeling and applications. ISSS J Micro Smart Syst 9, 1–32 (2020). https://doi.org/10.1007/s41683-020-00050-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41683-020-00050-5