Abstract

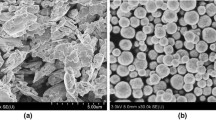

Ag sinter-joining is an ideal connection technique for next-generation power electronics packaging due to its excellent high-temperature stability and excellent thermal conductivity. In this work, we applied Ag sinter-joining to die attach of power electronics and focused reliability of Ag sinter-joining under a harsh thermal cycling condition, which ranges from − 50 to 250 ℃. The bonding quality of as-sintered die attach had a shear strength of over 45 MPa and remained over 25 MPa after a 500-cycle test. However, the shear strength drastically degraded to less than 10 MPa due to a failure of metallization layer detachment between dummy chip and sputtering layer after 750 cycles. Meanwhile, thermal resistance of die attach with different bonding materials was also evaluated by a T3ster, which suggests the Ag sinter-joining owns a superior property of thermal conduction than the traditional solder joining. This investigation indicates that the Ag sinter-joining has a long lifetime under a severe operating condition of power electronics.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Yoder MN (1996) Wide bandgap semiconductor materials and devices. IEEE Trans Electron Devices 43:1633–1636

Yu F, Johnson RW, Hamilton MC (2015) Pressureless sintering of microscale silver paste for 300 ℃ applications. IEEE Trans Compon Packag Manuf Technol 5:1258–1264

Zhang Z, Chen C, Yang Y, Zhang H, Kim D, Sugahara T, Nagao S, Suganuma K (2019) Low-temperature and pressureless sinter joining of Cu with micron/submicron Ag particle paste in air. J Alloys Compd 780:435–442

Suganuma K, Sakamoto S, Kagami N, Wakuda D, Kim K-S, Nogi M (2012) Low-temperature low-pressure die attach with hybrid silver particle paste. Microelectron Reliab 52:375–380

Wang S, Li M, Ji H, Wang C (2013) Rapid pressureless low-temperature sintering of Ag nanoparticles for high-power density electronic packaging. Scripta Mater 69:789–792

Zhang Z, Chen C, Kim D, Suetake A, Nagao S, Suganuma K (2020) Bonding and high-temperature storage performance of die attachment with Ag paste sintering on bare direct bonding aluminum (DBA) substrate. In: TMS 2020 149th annual meeting & exhibition supplemental proceedings. Springer, pp 697–706

Zhang Z, Chen C, Suganuma K, Kurosaka S (2019), Effect of substrate preheating treatment on thermal reliability and micro-structure of Ag paste sintering on Au surface finish. In: 2019 IEEE 69th electronic components and technology conference (ECTC), IEEE, pp 474–478

Chew LM, Schmitt W, Dubis M (2018) High bonding strength of silver sintered joints on non-precious metal surfaces by pressure sintering under air atmosphere using micro-silver sinter paste. In: 2018 IEEE 20th electronics packaging technology conference (EPTC), IEEE, pp 125–131

Jiu J, Zhang H, Nagao S, Sugahara T, Kagami N, Suzuki Y, Akai Y, Suganuma K (2016) Die-attaching silver paste based on a novel solvent for high-power semiconductor devices. J Mater Sci 51:3422–3430

Presland A, Price G, Trimm D (1972) Hillock formation by surface diffusion on thin silver films. Surf Sci 29:424–434

Parker W, Jenkins R, Butler C, Abbott G (1961) Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity. J Appl Phys 32:1679–1684

Manikam VR, Cheong KY (2011) Die attach materials for high temperature applications: a review. IEEE Trans Compon Packag Manuf Technol 1:457–478

Amalu EH, Ekere N (2012) Damage of lead-free solder joints in flip chip assemblies subjected to high-temperature thermal cycling. Comp Mater Sci 65:470–484

Acknowledgements

This paper is based on results obtained from a project (JPNP14004) commissioned by the New Energy and Industrial Technology Development Organization (NEDO). The author acknowledges the Comprehensive Analysis Center of Osaka University for the use of and TG-DTA, Daicel Company in Japan for providing the solvent, and the Network Joint Research Centre for Materials and Devices, Dynamic Alliance for Open Innovation Bridging Human, Environment and Materials.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Zhang, Z., Chen, C., Suetake, A., Hsieh, MC., Iwaki, A., Suganuma, K. (2021). Reliability Evaluation of Ag Sinter-Joining Die Attach Under a Harsh Thermal Cycling Test. In: TMS 2021 150th Annual Meeting & Exhibition Supplemental Proceedings. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-65261-6_63

Download citation

DOI: https://doi.org/10.1007/978-3-030-65261-6_63

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-65260-9

Online ISBN: 978-3-030-65261-6

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)