Abstract

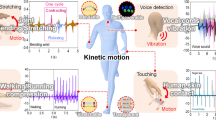

Controllable formation of microstructures in the assembled graphene film could tune the physical properties and broaden its applications in flexible electronics. Many efforts have been made to control the formation of wrinkles and ripples in graphene films. However, the formation of orderly wrinkles in graphene film remains a challenge. Here, we reported a simple strategy for the fabrication of graphene film with periodic and parallel wrinkles with a pre-stretched polydimethylsiloxane substrate. The width of the wrinkles in graphene can be controlled by changing the pre-stretched strain of the substrate. The average width of wrinkles in graphene film on the substrate with pre-stretched strain of 10%, 20%, and 50% was about 3.68, 2.99 and 2.01 µm, respectively. The morphological evolution of wrinkled double-layered graphene under mechanical deformation was observed and studied. Furthermore, a strain sensor was constructed based on the wrinkled graphene, showing high sensitivity, large working range and excellent cyclic stability. These strain sensors show great potential in real-time motion detection, health surveillance and electronic skins.

摘要

石墨烯薄膜中可控的微纳结构, 有利于调控其物理性质并拓 宽其在柔性电子器件中的应用. 近年来, 研究人员致力于控制石墨 烯薄膜中褶皱、起伏波纹等微纳结构的形成. 但是, 在石墨烯薄膜 中可控地形成有序的褶皱状结构仍然面临巨大挑战. 本文报道了 一种简单地制备具有周期性平行褶皱结构的石墨烯薄膜的方法, 即通过将溶液表面自组装形成的石墨烯薄膜转移至预拉伸的聚二 甲基硅氧烷(PDMS)基底上而得到. 制备的石墨烯薄膜中, 褶皱的宽 度可以简单地通过改变基底的预拉伸形变来控制. 当PDMS基底预 拉伸应变分别为10%、20%和50%时, 薄膜中褶皱的平均宽度分别 为3.68、2.99和2.01 µm. 本文还进一步研究和分析了双层堆叠、褶 皱状石墨烯薄膜, 在拉伸形变时的形貌结构变化. 此外, 本文基于该 褶皱状石墨烯薄膜, 构建了应变传感器. 该传感器展现出高灵敏 度、宽探测范围和优良的循环稳定性, 其在实时运动探测、健康 监测和电子皮肤等领域有着广阔应用前景.

Similar content being viewed by others

References

Cai S, Xu X, Yang W, et al. Materials and designs for wearable photodetectors. Adv Mater, 2019, 31: 1808138

Xu K, Zhou R, Takei K, et al. Toward flexible surface-enhanced Raman scattering (SERS) sensors for point-of-care diagnostics. Adv Sci, 2019, 6: 1900925

Wang B, Facchetti A. Mechanically flexible conductors for stretchable and wearable E-skin and E-textile devices. Adv Mater, 2019, 31: 1901408

Chen W, Gui X, Yang L, et al. Wrinkling of two-dimensional materials: Methods, properties and applications. Nanoscale Horiz, 2019, 4: 291–320

Jian M, Wang C, Wang Q, et al. Advanced carbon materials for flexible and wearable sensors. Sci China Mater, 2017, 60: 1026–1062

Wang C, Xia K, Wang H, et al. Advanced carbon for flexible and wearable electronics. Adv Mater, 2019, 31: 1801072

Afroj S, Karim N, Wang Z, et al. Engineering graphene flakes for wearable textile sensors via highly scalable and ultrafast yarn dyeing technique. ACS Nano, 2019, 13: 3847–3857

Jung YH, Park B, Kim JU, et al. Bioinspired electronics for artificial sensory systems. Adv Mater, 2019, 31: 1803637

Huang H, Su S, Wu N, et al. Graphene-based sensors for human health monitoring. Front Chem, 2019, 7: 399

Zheng S, Zeng M, Cao H, et al. Insight into the rapid growth of graphene single crystals on liquid metal via chemical vapor deposition. Sci China Mater, 2019, 62: 1087–1095

Kim KS, Zhao Y, Jang H, et al. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature, 2009, 457: 706–710

Lee Y, Bae S, Jang H, et al. Wafer-scale synthesis and transfer of graphene films. Nano Lett, 2010, 10: 490–493

Ma Y, Zheng Y, Zhu Y. Towards industrialization of graphene oxide. Sci China Mater, 2019, 62: 1087–1095

Hempel M, Nezich D, Kong J, et al. A novel class of strain gauges based on layered percolative films of 2D materials. Nano Lett, 2012, 12: 5714–5718

Jiang WS, Liu ZB, Xin W, et al. Reduced graphene oxide nanoshells for flexible and stretchable conductors. Nanotechnology, 2016, 27: 095301

Yang Z, Wang DY, Pang Y, et al. Simultaneously detecting subtle and intensive human motions based on a silver nanoparticles bridged graphene strain sensor. ACS Appl Mater Interfaces, 2018, 10: 3948–3954

Wang DY, Tao LQ, Liu Y, et al. High performance flexible strain sensor based on self-locked overlapping graphene sheets. Nanoscale, 2016, 8: 20090–20095

Li X, Yang T, Yang Y, et al. Large-area ultrathin graphene films by single-step Marangoni self-assembly for highly sensitive strain sensing application. Adv Funct Mater, 2016, 26: 1322–1329

Park Y, Shim J, Jeong S, et al. Microtopography-guided conductive patterns of liquid-driven graphene nanoplatelet networks for stretchable and skin-conformal sensor array. Adv Mater, 2017, 29: 1606453

Chae SH, Yu WJ, Bae JJ, et al. Transferred wrinkled Al2O3 for highly stretchable and transparent graphene-carbon nanotube transistors. Nat Mater, 2013, 12: 403–409

Liu Q, Chen J, Li Y, et al. High-performance strain sensors with fish-scale-like graphene-sensing layers for full-range detection of human motions. ACS Nano, 2016, 10: 7901–7906

Chen W, Gui X, Liang B, et al. Controllable fabrication of large-area wrinkled graphene on a solution surface. ACS Appl Mater Interfaces, 2016, 8: 10977–10984

Zang J, Ryu S, Pugno N, et al. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat Mater, 2013, 12: 321–325

Chen T, Xue Y, Roy AK, et al. Transparent and stretchable highperformance supercapacitors based on wrinkled graphene electrodes. ACS Nano, 2014, 8: 1039–1046

Thomas AV, Andow BC, Suresh S, et al. Controlled crumpling of graphene oxide films for tunable optical transmittance. Adv Mater, 2015, 27: 3256–3265

Lee WK, Kang J, Chen KS, et al. Multiscale, hierarchical patterning of graphene by conformal wrinkling. Nano Lett, 2016, 16: 7121–7127

Leem J, Wang MC, Kang P, et al. Mechanically self-assembled, three-dimensional graphene-gold hybrid nanostructures for advanced nanoplasmonic sensors. Nano Lett, 2015, 15: 7684–7690

Gabardo CM, Yang J, Smith NJ, et al. Programmable wrinkling of self-assembled nanoparticle films on shape memory polymers. ACS Nano, 2016, 10: 8829–8836

Chen PY, Sodhi J, Qiu Y, et al. Multiscale graphene topographies programmed by sequential mechanical deformation. Adv Mater, 2016, 28: 3564–3571

Yang YF, Tao LQ, Pang Y, et al. An ultrasensitive strain sensor with a wide strain range based on graphene armour scales. Nanoscale, 2018, 10: 11524–11530

Tian H, Shu Y, Cui YL, et al. Scalable fabrication of high-performance and flexible graphene strain sensors. Nanoscale, 2014, 6: 699–705

Yun T, Kim H, Iqbal A, et al. Electromagnetic shielding of monolayer MXene assemblies. Adv Mater, 2020, 32: 1906769

Kim HH, Lee SK, Lee SG, et al. Wetting-assisted crack- and wrinkle-free transfer of wafer-scale graphene onto arbitrary substrates over a wide range of surface energies. Adv Funct Mater, 2016, 26: 2070–2077

Feng C, Yi Z, Dumée LF, et al. Shrinkage induced stretchable micro-wrinkled reduced graphene oxide composite with recoverable conductivity. Carbon, 2015, 93: 878–886

Chu JH, Lee DH, Jo J, et al. Highly conductive and environmentally stable organic transparent electrodes laminated with graphene. Adv Funct Mater, 2016, 26: 7234–7243

Takei A, Jin L, Fujita H, et al. High-aspect-ratio ridge structures induced by plastic deformation as a novel microfabrication technique. ACS Appl Mater Interfaces, 2016, 8: 24230–24237

Ahadian S, Estili M, Surya VJ, et al. Facile and green production of aqueous graphene dispersions for biomedical applications. Nanoscale, 2015, 7: 6436–6443

Bae SH, Lee Y, Sharma BK, et al. Graphene-based transparent strain sensor. Carbon, 2013, 51: 236–242

Zhu W, Low T, Perebeinos V, et al. Structure and electronic transport in graphene wrinkles. Nano Lett, 2012, 12: 3431–3436

Feng C, Yi Z, Dumée LF, et al. Tuning micro-wrinkled graphene films for stretchable conductors of controllable electrical conductivity. Carbon, 2018, 139: 672–679

Rolnick H. Tension coefficient of resistance of metals. Phys Rev, 1930, 36: 506–512

Pang Y, Tian H, Tao L, et al. Flexible, highly sensitive, and wearable pressure and strain sensors with graphene porous network structure. ACS Appl Mater Interfaces, 2016, 8: 26458–26462

Park JJ, Hyun WJ, Mun SC, et al. Highly stretchable and wearable graphene strain sensors with controllable sensitivity for human motion monitoring. ACS Appl Mater Interfaces, 2015, 7: 6317–6324

Wang Y, Wang Y, Yang Y. Graphene-polymer nanocompositebased redox-induced electricity for flexible self-powered strain sensors. Adv Energy Mater, 2018, 8: 1800961

Chun S, Choi Y, Park W. All-graphene strain sensor on soft substrate. Carbon, 2017, 116: 753–759

Yan C, Wang J, Kang W, et al. Highly stretchable piezoresistive graphene-nanocellulose nanopaper for strain sensors. Adv Mater, 2014, 26: 2022–2027

Liu Q, Zhang M, Huang L, et al. High-quality graphene ribbons prepared from graphene oxide hydrogels and their application for strain sensors. ACS Nano, 2015, 9: 12320–12326

Jeong YR, Park H, Jin SW, et al. Highly stretchable and sensitive strain sensors using fragmentized graphene foam. Adv Funct Mater, 2015, 25: 4228–4236

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (51772335), and the Science and Technology Program of Guangzhou (201904010450).

Author information

Authors and Affiliations

Contributions

Jia Y and Chen W directed the research. Ye C performed the graphene synthesis under the supervision of Lin CT. Gui X supervised the project and conceived the experiments. Yang R, Yang L, and Hu Q carried out samples transfer and performed the tests such as SEM, Raman. Zhang Z and Liang B carried out the mechanicalelectrical measurements. Jia Y, Chen W, Yang BR, Tang Z, Lin CT and Gui X analyzed the experimental data, designed the figures and co-wrote the manuscript. All authors contributed to the general discussion.

Corresponding authors

Additional information

Conflict of interest

The authors declare no conflict of interest.

Yufei Jia received her Bachelor’s degree from Hefei University of Technology in 2017. She is a postgraduate student at Sun Yat-sen university now. Her research interest is graphene-based strain sensors.

Wenjun Chen obtained his PhD majored in condensed matter physics at Sun Yat-sen University in 2018. Now he is working as a Postdoctoral researcher at Tsinghua-Berkeley Shenzhen Institute (TBSI), Tsinghua University. His research is focused on the preparation of 2D materials for applications in flexible sensors.

Cheng-Te Lin received his PhD degree in materials science and engineering at Tsing Hua University (Hsin-Chu) in 2008. In 2012, he was a postdoc at Massachusetts Institute of Technology (MIT, USA). Since 2014 June, he is working as a full professor at Ningbo Institute of Material Technology and Engineering. His research interests focus on the development of graphenebased applications, including functional composites, thermal interface materials, and biosensors.

Xuchun Gui received his PhD degree in materials science and engineering at Tsinghua University in 2011. Then, He joined Sun Yat-Sen University as an assistant professor in 2011, and appointed as an associate professor in 2014. From 2014 to 2015 he worked as a visiting professor at The Hong Kong University of Science and Technology. His research interests focus on the synthesis of carbon nanomaterials and 2D materials, and their applications in flexible optoelectronics and sensor devices.

Supplementary information

Supporting data are available in the online version of the paper.

Supplementary information

40843_2020_1314_MOESM1_ESM.pdf

Controllable formation of periodic wrinkles in Marangoni-driven self-assembled graphene film for sensitive strain detection

Rights and permissions

About this article

Cite this article

Jia, Y., Chen, W., Ye, C. et al. Controllable formation of periodic wrinkles in Marangoni-driven self-assembled graphene film for sensitive strain detection. Sci. China Mater. 63, 1983–1992 (2020). https://doi.org/10.1007/s40843-020-1314-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-020-1314-1