Abstract

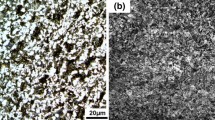

The downhole casing and tubing in thermal recovery wells are the main channels for fluid flow. The corrosion for casing and tubing in high pressure (5 MPa) and high temperature (200 °C) (HPHT) fluid can cause string failure due to wall thinning, deformation, and fracture. In order to study the corrosion characteristics of J55 casing steel and N80 tubing steel in HPHT environment containing CO2 and NaCl, corrosion and corrosion inhibition experiments were carried out using a rotating autoclave at a pressure of 5 MPa and 50–200 °C environment. Morphologies and compositions of corrosion products were analyzed by SEM and XRD. HPHT corrosion process was discussed by Arrhenius equation and the transition state equation. Results showed that the corrosion rates of the two materials increased with CO2 partial pressure while increased initially and then decreased with increasing temperature. In CO2–NaCl solution, the saturate NaCl decreased the CO2 corrosion rates at low temperature (inhibition) and increased CO2 corrosion rates at high temperature. Meanwhile, SEM results showed that the surfaces of CO2 corrosion became more dense and uniform at high temperature. The increase of NaCl leaded to pitting and high concentration NaCl solution causes granular products to appear on the CO2 corrosion surface. The carbon steel corrosion rate is mainly controlled by kinetic parameters of activation; the activation parameters were increased by the increase in temperature and NaCl concentration. Oil-soluble imidazoline acts as a good inhibitor for corrosion of J55 and N80 in this work.

Similar content being viewed by others

References

Chen S, Pan JJ, Wang MJ, Chen DY, Cheng JR (2020) Experimental study on flow-induced corrosion of casing and tubing steel for heavy oil thermal recovery wells. Mater Sci Forum 993:1183–1189

Hu Q, Guo X, Zhang G, Dong Z (2011) The corrosion behavior of carbon steel in CO2-saturated NaCl crevice solution containing acetic acid. Mater Corros 63:720–728

Lindström R, Johansson LG, Svensson JE (2003) The influence of NaCl and CO2 on the atmospheric corrosion of magnesium alloy AZ91. Mater Corros 53:587–594

Singh A, Lin YH, Ebenso EE, Liu WY, Pan J, Huang B (2015) Gingko biloba fruit extract as an eco-friendly corrosion inhibitor for J55 steel in CO2 saturated 3.5% NaCl solution. J Ind Eng Chem 24:219–228

Bai HT, Wang YQ, Ma Y, Zhang QB, Zhang NS (2018) Effect of CO2 partial pressure on the corrosion behavior of J55 carbon steel in 30% crude oil/brine mixture. Materials 11:1765

Bharatiya U, Gal P, Agrawal A, Shah M, Sircar A (2019) Effect of corrosion on crude oil and natural gas pipeline with emphasis on prevention by ecofriendly corrosion inhibitors: a comprehensive review. J Bio Tribo Corros 5:35

Zhang GA, Liu D, Li YZ, Guo XP (2017) Corrosion behavior of N80 carbon steel in formation water under dynamic supercritical CO2 condition. Corros Sci 120:107–120

Pal S, Bhadauria SS, Kumar P (2019) Pitting corrosion behavior of F304 stainless steel under the exposure of ferric chloride solution. J Bio Tribo Corros 5:91

Zhang J, Zhao WZ (2011) Electrochemical noise analysis of pitting corrosion of J55 steel in NaCl+NaHCO3 electrolytes. Surf Interface Anal 43:1018–1021

Song GL, Atrens A, John ST, D, Wu X, Nairn J, (1997) The anodic dissolution of magnesium in chloride and sulphate solutions. Corros Sci 39:1981–2004

Yue XQ, Zhao MF, Zhang L, Zhang HJ, Li DP, Lu MX (2018) Correlation between electrochemical properties and stress corrosion cracking of super 13Cr under an HPHT CO2 environment. Royal Soc Chem 8:24679–24689

Sun JB, Sun Ch, Zhang GA, Zhao WM, Wang Y (2016) Effect of water cut on the localized corrosion behavior of P110 tube steel in supercritical CO2/oil/water environment. Corrosion 72:1470–1482

Jiang X, Zheng YG, Qu DR, Ke W (2006) Effect of calcium ions on pitting corrosion and inhibition performance in CO2 corrosion of N80 steel. Corros Sci 48:3091–3108

Jiang JR, Xie YS, Islam MA, Stack MM (2017) The effect of dissolved oxygen in slurry on erosion-corrosion of En30B steel. J Bio Tribo Corros 3:45

Li DG, Feng YR, Bai ZQ, Zheng MS (2007) Characteristics of CO2 corrosion scale formed on N80 steel in stratum water with saturated CO2. Appl Surf Sci 253:8371–8376

Kermani MB, Morshed A (2003) Carbon dioxide corrosion in oil and gas production-a compendium. Corrosion 59:659–683

Videm K, Kvarekval J (1995) Corrosion of carbon steel in carbon dioxide-saturated solutions containing small amounts of hydrogen sulfide. Corrosion 51:260–269

Hong T, Sun YH, Jepson WP (2002) Study on corrosion inhibitor in large pipelines under multiphase flow using EIS. Corros Sci 44:101–112

Ogundele GI, White WE (1986) Some observations on corrosion of carbon steel in aqueous environments containing carbon dioxide. Corrosion 42:71–78

Nesic S, Postlethwaite J, Olsen S (1996) An electrochemical model for prediction of corrosion of mild steel in aqueous carbon dioxide solutions. Corrosion 52:280–294

López DA, Schreiner WH, Sánchez SRD, Simison SN (2003) The influence of carbon steel microstructure on corrosion layers: an XPS and SEM characterization. Appl Surf Sci 207:69–85

Chokshi K, Sun W, Nesic S (2005) Iron carbonate scale growth and the effect of inhibition in CO2 corrosion of mild steel. NACE International, April 3–7, Houston TX, Corrosion, 2005, Paper no. 05285

Du J, Guo JH, Zhao LQ, Chen YX, Liu CL, Meng XH (2018) Corrosion inhibition of N80 steel simulated in an oil field acidification environment. Int J Electro Sci 13:5810–5823

Abdel Hameed RS (2017) Solvent free glycolysis of plastic waste as green corrosion inhibitor for carbon steel in sulfuric acid. J New Mater Electro Sys 20:141–149

Abdallah M, Abdel Hameed RS (2018) Corrosion inhibition of carbon steel in 1M hydrochloric acid using some pyrazolo[3,4-d]pyrimidnone derivatives. Prot Met Phys Chem Surf 54:113–121

Yadav M, Kumar S, Purkait T, Olasunkanmi LO, Bahadur I, Ebenso EE (2016) Electrochemical, thermodynamic and quantum chemical studies of synthesized benzimidazole derivatives as corrosion inhibitors for N80 steel in hydrochloric acid. J Mol Liq 213:122–138

Yang Z, Zhan FT, Pan Y, LYu, Z F, Han C Y, Hu Y P, Ding P P, Gao T H, Zhou X Y, Jiang Y N, (2015) Structure of a novel benzyl quinolinium chloride derivative and its effective corrosion inhibition in 15 wt.% hydrochloric acid. Corros Sci 99:281–294

Abdel Hameed RS (2019) Schiff’ bases as corrosion inhibitor for aluminum alloy in hydrochloric acid medium. Tenside Surf Deterg 56:209–215

Ibrahim MM, Abdel Hameed RS, Abu-Nawwas Abd-Alhakeem H, Mohamad Sawsan E (2014) Schiff’s bases and their metal complexes as corrosion inhibitors for aluminum alloys in corrosive media. J Org Chem 10:271–281

Abdel Hameed RS, Ismail OM, Eissa FM, Ghanem R (2012) New non ionic polymeric surfactants as corrosion inhibitors for the C-Steel alloy in hydrochloric acid corrosive medium. Der Chem Sin 3:236–248

Abdel Hameed RS (2018) Cationic surfactant-zn+2 systems as mixed corrosion inhibitors for carbon steel in a sodium chloride corrosive medium. Portugaliae Electrochim Acta 36:271–283

Abdel Hameed RS (2011) Ranitidine drugs as non-toxic corrosion inhibitors for mild steel in hydrochloric acid medium. Portugaliae Electrochim Acta 29:273–285

Abdel Hameed RS (2009) Expired ranitidine drugs as green corrosion inhibitor for aluminum in 1M hydrochloric acid. Al-Azhar Bull Sci 20:150

Abdel Hameed RS (2013) Expired drugs as corrosion inhibitors for metals and alloys. Phys Chem: PCAIJ 8:146–149

Abdallah M, Fawzy A, Hawsawi H, Abdel Hameed RS, Al-Juaid Salih S (2020) Estimation of water-soluble polymers (poloxamer and pectin) as corrosion inhibitors for carbon steel in acidic medium. Int J Electrochem Sci 15:8129–8144

Abdel Hameed RS, Alfakeer M, Abdallah M (2018) Inhibiting properties of some heterocyclic amide derivatives as potential nontoxic corrosion inhibitors for carbon steel in 1.0 M sulfuric acid. Surf Eng Appl Electrochem 54(6):599–606

Abdallah M, Al-abdali FH, Abdel Hameed RS, Kamar EM, El-Sayed R (2020) Corrosion inhibition of aluminum in 1.0M HCl solution by some nonionic surfactant compounds containing five membered heterocyclic moiety. Chem Data Collect 28:100407

Abdel Hameed RS, Aljuhani EH, Al-Bagawi AH, Shamroukh AH, Abdallah M (2020) Study of sulfanyl pyridazine derivatives as efficient corrosion inhibitors for carbon steel in 1.0 M HCl using analytical techniques. Int J Corros Scale Inhib 9:623–643

Abdel Hameed RS, Elmetery Naser S, Alshemary Nawaf F, Shehata Hassan A (2016) Recycling of some plastic waste as green corrosion inhibitors for steelin 1 M phosphoric acid. Mater Sci J 14:417–4250

“Specification for casing and tubing”, API Specification 5CT-2011, American petroleum institute: Washington, USA, 2012

“Preparation, installation, analysis, and interpretation of corrosion coupons in oilfield operations”, NACE RP0775-2005, NACE International: Houston, TX, USA, 2005

Lin G, Bai Z, Zhao X (2006) Effect of temperature and pressure on the morphology of carbon dioxide corrosion scales. Corrosion 62:501–507

Yin ZF, Bai ZQ, Zhou WJ, Li B (2010) Effect of acetic acid on CO2 corrosion of carbon steel in NaCl solution. Surf Interface Anal 42:1483–1488

Hassani S, Roberts KP, Shirazi SA, Shadley JR, Rybicki EF, Joia C (2012) Flow loop study of NaCl concentration effect on erosion, corrosion, and erosion-corrosion of carbon steel in CO2-saturated systems. Corrosion 68:026001–026009

Alfakeer M, Abdallah M, Abdel Hameed RS (2020) Propoxylated fatty esters as safe inhibitors for corrosion of Zinc in hydrochloric acid. Prot Met Phys Chem Surf 56:4001–4003

Abdel Hameed RS, Al-Bagawi AH, Shehata Hassan A, Shamroukh Ahmed H, Abdallah M (2020) Corrosion inhibition and adsorption properties of some heterocyclic derivatives on C-steel surface in HCl. J Bio- Tribio Corros 6:51

Acknowledgements

This work was supported by the Basic Research Program of Natural Science of Shaanxi Province (No. 2019JQ-809) and the Youth Innovation Team of Xi’an Shiyou University (No. 2019QNKYCXTD10).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cui, L., Kang, W., You, H. et al. Experimental Study on Corrosion of J55 Casing Steel and N80 Tubing Steel in High Pressure and High Temperature Solution Containing CO2 and NaCl. J Bio Tribo Corros 7, 13 (2021). https://doi.org/10.1007/s40735-020-00449-5

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-020-00449-5