Abstract

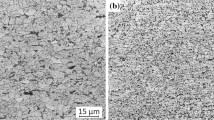

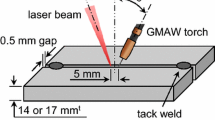

In this study, high-power disk laser–metal active gas arc hybrid welding was performed on thick plates of high-tensile-strength steel, HT780. The effect of shielding gas on the penetration, defects, and mechanical properties of the hybrid weld beads was investigated using either 80 %Ar–20 %CO2 or 100 %CO2 shielding gas. The results showed that the process window of laser powers for the production of sound welds was wider in 100 %CO2 gas, although more spatters occurred. Besides, the optimization of the arc parameters could reduce spattering significantly by controlling the globular transfer mode to form a buried arc. The Vickers hardness test was performed to identify the levels of hardening and softening in the bead and HAZ, respectively. The tensile test results showed that the tensile strengths of the joints hybrid-welded in either 80 %Ar–20 %CO2 or 100 %CO2 gas were much higher than those of the HT780 base material. The Charpy V-notch test results revealed that the values of the hybrid-welded joints in 80 %Ar–20 %CO2 gas were higher than those in 100 %CO2 gas. The reduction in toughness was attributed to the increase in the oxygen content and the consequent formation of a higher number of oxides in a weld bead made in 100 %CO2 gas.

Similar content being viewed by others

References

Atabaki MM, Ma J, Yang G, Kovacevic R (2014) Hybrid laser/arc welding of advanced high strength steel in different butt joint configurations. Mater Des 64:573–587

Fekete JR, Sowards JW, Amaro RL (2015) Economic impact of applying high strength steels in hydrogen gas pipelines. Int J Hydrogen Energy 40(33):10547–10558

Guo W, Crowther D, Francis JA, Thompson A, Liu Z, Li L (2015) Microstructure and mechanical properties of laser welded S960 high strength steel. Mater Des 85:534–548

Arif N, Chung H (2015) Alternating current–gas metal arc welding for application to thick plates. J Mater Process Technol 222:75–83

Zhang X, Ashida E, Tarasawa S, Anma Y, Okada M, Katayama S, Mizutani M (2011) Welding of thick stainless steel plates up to 50 mm with high brightness lasers. J Laser Appl 23(2):022002

Buddu RK, Chauhan N, Raole PM, Natu H (2015) Studies on mechanical properties, microstructure and fracture morphology details of laser beam welded thick SS304L plates for fusion reactor applications. Fusion Eng Des 95:34–43

Sokolov M, Salminen A, Katayama S, Kawahito Y (2015) Reduced pressure laser welding of thick section structural steel. J Mater Process Technol 219:278–285

Sathiya P, Mishra MK, Soundararajan R, Shanmugarajan B (2013) Shielding gas effect on weld characteristics in arc-augmented laser welding process of super austenitic stainless steel. Optics Laser Technol 45:46–55

Moradi M, Ghoreishi M, Frostevarg J, Kaplan AF (2013) An investigation on stability of laser hybrid arc welding. Optics Lasers Eng 51(4):481–487

Lahdo R, Seffer O, Springer A, Kaierle S, Overmeyer L (2014) GMA–laser hybrid welding of high-strength fine-grain structural steel with an inductive preheating. Phys Proc 56:637–645

Farrokhi F, Nielsen SE, Schmidt RH, Pedersen SS, Kristiansen M (2015) Effect of cut quality on hybrid laser arc welding of thick section steels. Phys Proc 78:65–73

Turichin G, Kuznetsov M, Sokolov M, Salminen A (2015) Hybrid laser arc welding of X80 steel: influence of welding speed and preheating on the microstructure and mechanical properties. Physics Procedia 78:35–44

Pan Q, Mizutani M, Kawahito Y, Katayama S (2016) High power disk laser-metal active gas arc hybrid welding of thick high tensile strength steel plates. J Laser Appl 28(1):012004

Ohnishi T, Kawahito Y, Mizutani M, Katayama S (2013) Butt welding of thick, high strength steel plate with a high power laser and hot wire to improve tolerance to gap variance and control weld metal oxygen content. Sci Technol Weld Joining 18(4):314–322

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission IV - Power Beam Processes

Rights and permissions

About this article

Cite this article

Pan, Q., Mizutani, M., Kawahito, Y. et al. Effect of shielding gas on laser–MAG arc hybrid welding results of thick high-tensile-strength steel plates. Weld World 60, 653–664 (2016). https://doi.org/10.1007/s40194-016-0333-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0333-9