Abstract

In the present study, an approach to model the dimensional accuracy (Δd), for different geometrical shapes, metal type/pouring temperatures in vacuum moulding (VM) have been proposed and applied by using Buckingham’s π-theorem. Three input parameters namely: pouring temperature; geometrical shape and vacuum pressure were selected to give output in form of Δd. This study provides main effects of these variables on Δd and shed light on mechanism of casting accuracy in VM.

Similar content being viewed by others

References

Bakhtiyarov SI, Overfelt R, Black MG, Weiss DJ (2005) Design and V-process production of cast magnesium component. Trans Am Foundry Men’s Soc J 113:879–886

Barua PB, Kumar P, Gaindhar JL (1996) Quality of V-process moulds through Taguchi’s technique. Int J Qual Reliab Eng 12:421–427

Bishop D, Bose S (1983) Mechanical properties of V-process molded steel castings. Trans Am Foundry Men’s Soc J 91:441–446

Gaindhar JL, Jain CK, Subbarathnanmaiah K (1985) Effect of sand variables on dimensional accuracy of Al-4% Cu alloy castings produced by V-process. Trans Am Foundry Men’s Soc J 93:303–306

Gouwens PR (2005) Vacuum molding (The V-process) perspective and into the future. Trans Am Foundry Men’s Soc J 94:98–174

Jain CK, Gaindhar JL (1986) Simulating behavior of sand under vacuum in V-process. Trans Am Foundry Men’s Soc J 94:86–107

Kumar P, Creese RC (1999) Effect of zircon sand (added to silica sand) surface finish of Al-11% SiC V-process. Trans Am Foundry Men’s Soc J 107:95–98

Kumar P, Creese RC (2001) Effect of fly ash addition on mechanical properties of Al-11% Si alloy castings produced by V-process. Trans Am Foundry Men’s Soc J 109:1–15

Kumar P, Gaindhar JL (1995) Off-line quality control for V-process castings. Qual Reliab Eng Int J 11:175–181

Kumar P, Gaindhar JLD (2002) Solidification time and mechanical properties of Al-11%Si alloy V-processed castings. Trans Am Foundry Men’s Soc J 104:635–638

Kumar P, Singh N, Goel P (1999) A multi-objective framework for the design of vacuum sealed molding process. Robot Comput Integr Manuf 15:413–422

Kumar S, Kumar P, Shan HS (2007) Effect of process parameters on the solidification time of Al-7% Si alloy castings produced by VAEPC process. Mater Manuf Process J 22:879–886

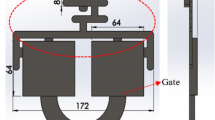

Pandher CS, Singh R (2011) Effect of geometrical shapes of patterns in vacuum moulding. Int J Adv Mechatron Robot 3(2):97–102

Singh R, Singh G (2015) Investigations of Al–SiC AMC prepared by vacuum moulding assisted stir casting. J Manuf Process 19:142–147

Singh R, Khamba JS (2009) Mathematical modeling of tool wear rate in ultrasonic machining of titanium. Int J Adv Manuf Technol 43(5–6):573–580

Singh R, Khamba JS (2009) Mathematical modeling of surface roughness in ultrasonic machining of titanium using Buckingham-∏ approach: a Review. Int J Abras Technol 2(1):3–24

Singh R (2014) Modeling of surface hardness in hot chamber die casting using Buckingham’s π approach. J Mech Sci Technol 28(2):699–704

Singh R, Podder D, Singh S (2015) Effect of single, double and triple particle size SiC and Al2O3 reinforcement on wear properties of AMC prepared by stir casting in vacuum mould. Trans Indian Inst Met Int J Min Met Mat Eng 68(5):791–797

Acknowledgements

The author is thankful to DST, New Delhi for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, R. Mathematical Modelling for Dimensional Accuracy in Vacuum Moulding. Proc. Natl. Acad. Sci., India, Sect. A Phys. Sci. 88, 65–71 (2018). https://doi.org/10.1007/s40010-016-0330-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40010-016-0330-9