Abstract

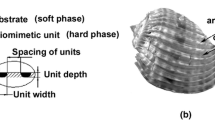

In this study, in effort to improve the sliding wear resistance of gray cast iron under wet lubrication conditions, specimens with different bionic units were manufactured and modified according to bionic theory. Inspired by the structure and appearance of biological wear-resistant skin, two kinds of bionic units were processed by laser on the specimen surfaces. We investigated the wear resistance properties of the samples via indentation method and then observed the wear surface morphology of specimens and the stress distributions. The results indicated that coupling the bionic units enhanced the wear resistance of the cast iron considerably compared to the other samples. We also determined the mechanism of wear resistance improvement according to the results.

Similar content being viewed by others

References

M. Ramadan, M. Takita, and H. Nomura, Effect of Semi-solid Processing on Solidification Microstructure and Mechanical Properties of Gray Cast Iron, Mater. Sci. Eng. A, 2006, 417(1–2), p 166–173

T. Yamazaki, T. Shibuya, C.J. Jin, T. Kikuta, and N. Nakatani, Lining of Hydraulic Cylinder Made of Cast Iron with Copper Alloy, J. Mater. Process. Technol., 2006, 172(1), p 30–34

G. Bertolino and J.E. Perez-Ipiña, Geometrical Effects on Lamellar Grey Cast Iron Fracture Toughness, J. Mater. Process. Technol., 2006, 179(1–3), p 202–206

T. Willidal, W. Bauer, and P. Schumacher, Stress/Strain Behaviour and Fatigue Limit of Grey Cast Iron, Mater. Sci. Eng. A, 2005, 413–414, p 578–582

J. Grum and R. Šturm, Laser Surface Melt-Hardening of Gray and Nodular Irons, Appl. Surf. Sci., 1997, 109–110, p 128–132

K.Y. Benyounis, O.M. Fakron, and J.H. Abboud, Rapid Solidification of M2 High-Speed Steel by Laser Melting, Mater. Des., 2009, 30(3), p 674–678

S. Lian and L. Chenglao, Effect of Laser Melting Processing on the Microstructure and Wear Resistance of Gray Cast Iron, Wear, 1991, 147(1), p 195–206

D.I. Pantelis, G. Pantazopoulos, and S.S. Antoniou, Wear behAvior of Anti-galling Surface Textured Gray Cast Iron Using Pulsed-CO2 Laser Treatment, Wear, 1997, 205(1–2), p 178–185

F. Fernandes, A. Cavaleiro, and A. Loureiro, Oxidation Behavior of Ni-Based Coatings Deposited by PTA on Gray Cast Iron, Surf. Coat. Technol., 2012, 207, p 196–203

Y.C. Lin, S.W. Wang, and K.E. Wu, The Wear Behaviour of Machine Tool Guideways Clad with W-Ni, W-Co and W-Cu Using Gas Tungsten Arc Welding, Surf. Coat. Technol., 2003, 172(2–3), p 158–165

J. Tong, B. Rong, J. Yan, Y. Ma, and B. Jia, Measuring Method for Abrasive Volume of Biomimetic Embossed Surfaces Using Reverse Engineering, Wear, 2008, 265(7–8), p 1114–1120

W.D. Bechert, M. Bruse, and W. Hage, Experiments with Three-Dimensional Riblets as an Idealized Model of Shark Skin, Exp. Fluids, 2000, 28(5), p 403–412

N. Sun, H. Shan, H. Zhou, D. Chen, X. Li, W. Xia, and L. Ren, Friction and Wear Behaviors of Compacted Graphite Iron with Different Biomimetic Units Fabricated by Laser Cladding, Appl. Surf. Sci., 2012, 258(19), p 7699–7706

H. Zhou, P. Zhang, N. Sun, C.-T. Wang, P.-Y. Lin, and L.-Q. Ren, Wear Properties of Compact Graphite Cast Iron with Bionic Units Processed by Deep Laser Cladding WC, Appl. Surf. Sci., 2010, 256(21), p 6413–6419

Z.-K. Chen, T. Zhou, H.-F. Zhang, W.-S. Yang, and H. Zhou, Influence of Orientations of Bionic Unit Fabricated by Laser Remelting on Fatigue Wear Resistance of Gray Cast Iron, J. Mater. Eng. Perform., 2015, 24(6), p 2511–2520

Z.H. Zhang, H. Zhou, L.Q. Ren, X. Tong, H.Y. Shan, and Y. Cao, Tensile Property of H13 Die Steel with Convex-Shaped Biomimetic Surface, Appl. Surf. Sci., 2007, 253(22), p 8939–8944

C. Wang, H. Zhou, Z. Zhang, Y. Zhao, D. Cong, C. Meng, P. Zhang, and L. Ren, Mechanical Property of a Low Carbon Steel with Biomimetic Units in Different Shapes, Opt. Laser Technol., 2013, 47, p 114–120

H. Zhou, X. Tong, Z. Zhang, X. Li, and L. Ren, The Thermal Fatigue Resistance of Cast Iron with Biomimetic Non-smooth Surface Processed by Laser with Different Parameters, Mater. Sci. Engi. A, 2006, 428(1–2), p 141–147

C. Meng, H. Zhou, Y. Zhou, M. Gao, X. Tong, D. Cong, C. Wang, F. Chang, and L. Ren, Influence of Different Temperatures on the Thermal Fatigue Behavior and Thermal Stability of Hot-Work Tool Steel Processed by a Biomimetic Couple Laser Technique, Opt. Laser Technol., 2014, 57, p 57–65

H. Zhou, Z.H. Zhang, L.Q. Ren, Q.F. Song, and L. Chen, Thermal Fatigue Behavior of Medium Carbon Steel with Striated Non-smooth Surface, Surf. Coat. Technol., 2006, 200(24), p 6758–6764

L. Tian, X. Tian, Y. Wang, G. Hu, and L. Ren, Anti-wear Properties of the Molluscan Shell Scapharca subcrenata: Influence of Surface Morphology, Structure and Organic Material on the Elementary Wear Process, Mater. Sci. Eng. C, 2014, 42, p 7–14

S. Kamat, X. Su, R. Ballarini, and A.H. Heuer, Structural Basis for the Fracture Toughness of the Shell of the Conch Strombus gigas, Nature, 2000, 405(6790), p 1036–1040

N. Sun, H. Shan, H. Zhou, D. Chen, X. Li, W. Xia, and L. Ren, Friction and Wear Behaviors of Compacted Graphite Iron with Different Biomimetic Units Fabricated by Laser Cladding, Appl. Surf. Sci., 2012, 258(19), p 7699–7706

H. Zhou, N. Sun, H. Shan, D. Ma, X. Tong, and L. Ren, Bio-inspired Wearable Characteristic Surface: Wear Behavior of Cast Iron with Biomimetic Units Processed by Laser, Appl. Surf. Sci., 2007, 253, p 9513–9520

Z. Pang, H. Zhou, G. Xie, D. Cong, C. Meng, and L. Ren, Effect of Bionic Coupling Units’ Forms on Wear Resistance of Gray Cast Iron Under Dry Linear Reciprocating Sliding Condition, Opt. Laser Technol., 2015, 70, p 89–93

M. Nakano, A. Korenaga, A. Korenaga, K. Miyake, T. Murakami, Y. Ando, H. Usami, and S. Sasaki, Applying Micro-texture to Cast Iron Surfaces to Reduce the Friction Coefficient Under Lubricated Conditions, Tribol. Lett., 2007, 28, p 131–137

H. Zhou, L. Chen, W. Wang, L.Q. Ren, H.Y. Shan, and Z.H. Zhang, Abrasive Particle Wear Behavior of 3Cr2W8V Steel Processed to Bionic Non-smooth Surface by Laser, Mater. Sci. Eng. A, 2005, 412, p 323–327

X. Wang, W. Liu, F. Zhou, and D. Zhu, Preliminary Investigation of the Effect of Dimple Size on Friction in Line Contacts, Tribol. Int., 2009, 42, p 1118–1123

N. Sun, Influences of various biomimetic coupling units on the friction and wear behaviors of compacted graphite cast iron, Jilin university, Changchun, 2010, p 105–106

A. Kovalchenko, O. Ajayi, A. Erdemir, G. Fenske, and I. Etsion, The Effect of Laser Texturing of Steel Surfaces and Speed-Load Parameters on the Transition of Lubrication Regime from Boundary to Hydrodynamic, Tribol. Trans., 2004, 47(2), p 299–307

Acknowledgments

This article was supported by Project 985—High Performance Materials of Jilin University and the Project 985—Bionic Engineering Science and Technology Innovation and National Natural Science Foundation of China (No. 51275200).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Zhang, P., Sui, Q. et al. Influence of Multiple Bionic Unit Coupling on Sliding Wear of Laser-Processed Gray Cast Iron. J. of Materi Eng and Perform 26, 1614–1625 (2017). https://doi.org/10.1007/s11665-017-2600-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2600-3