Abstract

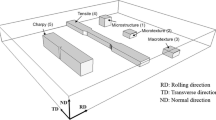

Air-water spray cooling was employed during a heat treatment to enhance the mechanical properties of microalloyed medium carbon steel test cylinders (38MnVS6, 88 mm diameter). Using appropriate cooling times and intensities, the test cylinders’ surfaces could be quenched and subsequently self-tempered by the residual heat of the core. Simultaneously, it was possible to keep the core regions of the cylinders in the bainitic regime and carry out a quasi-isothermal holding. The resulting microstructures consisted of tempered martensite (near-surface) and bainite with pearlite and ferrite (core). Compared to the standard heat treatment (controlled air cooling), the tensile properties (proof stress and ultimate tensile strength) could be improved for both near-surface and core regions with the adapted spray cooling. A hardness profile with 450 HV10 surface hardness and a hardening depth of more than 11 mm could be realized. In addition, an increase of the impact toughness for the core was achieved, resulting in approximately 25 J charpy impact energy. This is a substantial improvement compared to standard heat treatment procedure and values reported in the literature and can be attributed to the reduced pearlite volume fraction and the increased amount of fine bainite.

Similar content being viewed by others

References

B. Huchtemann and V. Schüler, Entwicklungsstand der ausscheidungshärtenden ferritisch-perlitischen (AFP-) Stähle mit Vanadinzusatz für eine geregelte Abkühlung von der Warmformgebungstemperatur (Stage of development of precipitation hardening, ferritic-perlitic steels with vanadium for controlled cooling from forging temperature), Technische Berichte - Thyssen-Edelstahl, 1990, 16(1), p 3–11 (in German)

D. Naylor, Microalloyed Forging Steels, Mater. Sci. Forum, 1998, 284–286, p 83–94

W. Bleck, C. Keul, and B. Zeislmair, Entwicklung eines höherfesten mikrolegierten ausscheidungshärtenden ferritisch/perlitischen Schmiedestahls AFP-M (The development of a high-strength, microalloyed, precipitation hardening, ferritic-perlitic formed steel AFP-M), Schmiede J., 2010, 3, p 42–44 (in German)

R. Kaspar, I. Gonzalez-Baquet, J. Richter, G. Nussbaum, and A. Kothe, New Post Forging Treatment of Medium Carbon Microalloyed Steels, Steel Res., 1997, 68(6), p 266–271

I. González-Baquet, R. Kaspar, J. Richter, G. Nussbaum, and A. Kothe, Influence of Microalloying on the Mechanical Properties of Medium Carbon Forging Steels After a Newly Designed Post Forging Treatment, Steel Res., 1997, 68(12), p 534–540

D. Rasouli, S.K. Asl, A. Akbarzadeh, and G. Daneshi, Effect of Cooling Rate on the Microstructure and Mechanical Properties of Microalloyed Forging Steel, J. Mater. Process. Technol., 2008, 206(1–3), p 92–98

T. Gretzki, D. Rodman, L. Wolf, A. Dalinger, C. Krause, T. Hassel, and F.-W. Bach, Economic Surface Hardening by Spray Cooling, HTM, 2011, 66(5), p 290–296

D. Rodman, C. Krause, F. Nürnberger, F.-W. Bach, K. Haskamp, M. Kästner, and E. Reithmeier, Induction Hardening of Spur Gearwheels Made from 42CrMo4 Hardening and Tempering Steel by Employing Spray Cooling, Steel Res. Int., 2011, 82(4), p 329–336

F. Nürnberger, M. Diekamp, J. Moritz, L. Wolf, S. Hübner, B.-A. Behrens, Spray Cooling of Early Extracted Hot Stamped Parts, TMS 2014 Supplemental Proceedings, Wiley, 2014, p 983–990

M. Nowak, O. Golovko, F. Nürnberger, I. Frolov, and M. Schaper, Water-Air Spray Cooling of Extruded Profiles: Process Integrated Heat Treatment of the Alloy EN AW-6082, J. Mater. Eng. Perform., 2013, 22(9), p 2580–2587

W. Bleck, Abschlussbericht des AiF-Vorhabens IGF FV LN 8 “EcoForge – Energieeffiziente Produktion von Hochleistungsbauteilen“, Teilprojekt 1 "Tieftemperatur-Umwandlungsvorgänge in hochfesten Schmiedestählen", (Final report on the research project "Ecoforge – Energy efficient production of high performance parts"), 2014 (in German)

F. Ishikawa, T. Takahashi, and T. Ochi, Intragranular Ferrite Nucleation in Medium-Carbon Vanadium Steels, Metall. Mater. Trans. A, 1994, 25(5), p 929–936

H.K.D.H. Bhadeshia, Bainite in steels. Transformations, microstructure and properties. IOM Communications, London, 2001

L. Ceschini, A. Marconi, C. Martini, A. Morri, and A. Di Schino, Tensile and Impact Behaviour of a Microalloyed Medium Carbon Steel: Effect of the Cooling Condition and Corresponding Microstructure, Mater. Des., 2013, 45, p 171–178

I. Gutiérrez, Effect of Microstructure on the Impact Toughness of Nb-Microalloyed Steel: Generalisation of Existing Relations from Ferrite-Pearlite to High Strength Microstructures, Mater. Sci. Eng. A, 2013, 571, p 57–67

J.P. Houin, A. Simon, and G. Beck, Relationship Between Structure and Mechanical Properties of Pearlite Between 0.2% and 0.8%C, ISIJ Int., 1981, 21(10), p 726–731

D. François, Micromechanics and the Charpy Transition Curve, From Charpy to Present Impact Testing, D. François, A. Pineau, Ed., Elsevier, Amsterdam, London, 2002, p 21–32

J. Flügge, The Appearance of Cracks and Fractures in Metallic Materials, Stahleisen, Düsseldorf, 1996

S. Shanmugam, N.K. Ramisetti, R. Misra, T. Mannering, D. Panda, and S. Jansto, Effect of Cooling Rate on the Microstructure and Mechanical Properties of Nb-Microalloyed Steels, Mater. Sci. Eng. A, 2007, 460–461, p 335–343

V. Khlestov, E. Konopleva, and H. McQueen, Kinetics of Austenite Transformation During Thermomechanical Processes, Can. Metall. Q., 1998, 37(2), p 75–89

Acknowledgments

The authors thank the German Research Foundation (DFG) for financial support within the Project NU297/2-1 and the Institut für Umformtechnik und Umformmaschinen (IFUM) of the Leibniz Universität Hannover for supplying the material.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Herbst, S., Schledorn, M., Maier, H.J. et al. Process Integrated Heat Treatment of a Microalloyed Medium Carbon Steel: Microstructure and Mechanical Properties. J. of Materi Eng and Perform 25, 1453–1462 (2016). https://doi.org/10.1007/s11665-016-2004-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2004-9