Abstract

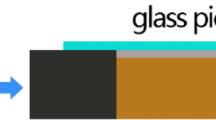

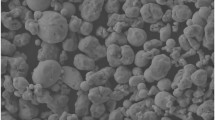

Transient liquid phase (TLP) bonding is a promising interconnection technology for high-temperature electronic packaging. In this paper, the effect of Cu particles on the microstructure and shear property of Cu/In-xCu/Cu TLP joints was investigated. The results show that Cu/In-xCu/Cu joint is mainly composed of an In and Cu11In9 phase after bonded for 60 min. A small amount of Cu2In phase forms at the interface of Cu/Cu11In9 with bonding time exceeding 300 min. The bonding efficiency and shear property of In-Cu mixed particle solder joint are superior to that of the In foil solder joint, because the bonding time was reduced and the shear strength of the solder joint was improved. The phase composition of Cu11In9 and Cu2In in the joint increased, the porosity decreased and the shear strength increased with increasing Cu content. When the Cu content of the In-xCu solder was 45 wt.%, the shear strength of the Cu/In-45Cu/Cu joint reached the peak value of 15.7 MPa.

Similar content being viewed by others

References

K. Sakiko and Y. Takeshi, JOM 70, 1 (2018).

K. Li, P. Evans, and M. Johnson, IET Electr. Syst. Transp. 8, 3 (2018).

K.S. Siow, S.T. Chua, and B.D. Beake, J. Mater. Sci-Mater. Electron. 30, 6212 (2019).

V.R. Manikam and K.Y. Cheong, IEEE Trans. Compon. Packag. Manuf. 1, 457 (2011).

Q. Xun, B. Xun, Z. Li, P.L. Wang, and Z.D. Cai, Renew. Sustain. Energy Rev. 70, 1336 (2017).

H.K. Shao, A.P. Wu, Y.D. Bao, Y. Zhao, and G.S. Zou, Trans. Nonferr. Met. Soc. 27, 722 (2017).

V.C. Nachiappan, J.H. Hattel, and J. Hald, Microelectron. Eng. 88, 981 (2011).

W.M. Chen, P. Mccloskey, and S.C. O’Mathuna, Microelectron. Reliab. 46, 896 (2006).

W. Nico, J. Shan, I.D. Liliana, and L. Christian, J. Mater. Eng. Perform. 23, 1585 (2014).

J. Cho, R. Sheikhi, S. Mallampati, and Y. Liang, in ECTC Conference Proceedings (2017), p 1553.

G. Wei, G.S. Zou, A.P. Wu, H.L. Bai, and J.L. Ren, Physica C 470, 115 (2010).

J.N. Calata, T.G. Lei, and G.Q. Lu, Int. J. Mater. Product Technol. 34, 95 (2009).

A. Sharif, C.L. Gan, and Z. Chen, J. Alloys Compd. 587, 365 (2014).

F. Yu, H. Liu, C. Hang, and M.Y. Li, JOM 71, 3049 (2019).

F. Brem, C. Liu and R. Déborah, in ESTC Conference Proceedings (2012), p 1.

J.F. Li, P.A. Agyakwa, and C.M. Johnson, Acta Mater. 59, 1198 (2011).

S.W. Yoon, M.D. Glover, and K. Shiozaki, IEEE Trans. Power Electron. 28, 2448 (2013).

H. Shao, A. Wu, Y. Bao, Y. Zhao, and G. Zou, J. Mater. Sci-Mater. Electron. 27, 4839 (2016).

T. Shuang, Z. Jian, X. Feng, R. Cao, and F. Wang, J. Mater. Sci-Mater. Electron. 29, 16388 (2018).

H.Y. Zhao, J.H. Liu, Z.L. Li, X.G. Song, Y.X. Zhao, H.W. Niu, H. Tian, H.J. Dong, and J.C. Feng, Metall. Mater. Trans. A 49, 2739 (2018).

P. Yao, X.Y. Li, X.B. Liang, B. Yu, F.Y. Jin, and Y. Li, Mater. Charact. 131, 49 (2017).

J.F. Li, P.A. Agyakwa, and C.M. Johnson, Acta Mater. 58, 3429 (2010).

A.A. Wronkowska, A. Wronkowski, and K. Kuklinski, Appl. Surf. Sci. 256, 4839 (2010).

G.T. Lim, B.J. Kim, and K. Lee, J. Electron. Mater. 38, 2228 (2009).

Y. Tian, C. Hang, X. Zhao, B. Liu, N. Wang, and C. Wang, J. Mater. Sci-Mater. Electron. 25, 4170 (2014).

J.B. Lee, H.Y. Hwang, and M.W. Rhee, J. Electron. Mater. 44, 435 (2015).

L. Litynska, J. Wojewoda, P. Zieba, M. Faryna, W. Gust, and E.J. Mittemeijer, Acta Mater. 145, 107 (2004).

Z. Wu, J. Cai, Q. Wang, J. Wang, and D. Wang, J. Electron. Mater. 46, 1 (2017).

Acknowledgments

This research was financially supported by the National Natural Science Foundation of China (Foundation No. 51865006) and Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant Nos. 19KJA430001 and 18KJA460001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Yang, L., Xu, Y.H. et al. Study on Microstructure and Shear Property of Cu/In-xCu/Cu Transient Liquid Phase Bonding Joints. J. Electron. Mater. 50, 217–223 (2021). https://doi.org/10.1007/s11664-020-08504-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-08504-0