Abstract

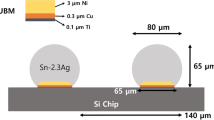

A nickel layer and a silver bonding layer have been deposited on copper electrodes over flex substrates to improve the bondability and die-shear force performance of chip–flex substrate assemblies when using the thermosonic flip-chip bonding process. For bonding temperature of 200°C, the maximum die-shear force was achieved by combining parameter values of 20.66 W ultrasonic power, 625 gf bonding force, and 0.5 s bonding time. The improved bondability and die-shear force could be attributed to better transfer of ultrasonic power across the bonding interface during thermosonic flip-chip bonding, owing to the high rigidity of the copper electrodes provided by the nickel layer. Experimental results also indicated that high bonding load is necessary at elevated ultrasonic power range to provide firm contact between the bumps and electrodes to enable smooth ultrasonic power transfer across the bonding interface. Moreover, prolonged bonding time caused cracks between the bumps and flex substrate. Close examination of the fracture morphologies after die-shear testing and after ultrasonic separation provided insight into the die-shear force performance as influenced by the process parameters and by the deposition of the nickel layer on the copper electrodes over the flex substrate.

Similar content being viewed by others

References

C.L. Chuang and J.N. Aoh, J. Electron. Mater. 35, 1693 (2006).

G.G. Harman, Wire Bonding in Microelectronics (New York: McGraw-Hill, 1997), p. 267.

C.L. Chuang and H.F. Fan, Microelectron. Eng. 88, 3080 (2011).

P. Palm, J. Maattanen, A. Tuominen, and E. Ristolainen, Microelectron. Reliab. 40, 633 (2001).

C.L. Chuang, Q.A. Liao, H.T. Li, S.J. Liao, and G.S. Huang, Microelectron. Eng. 87, 324 (2010).

J. Nave, Proceedings of ITAP (1996), p. 90.

C.L. Chuang, J.N. Aoh, Q.A. Liao, C.C. Hsu, S.J. Liao, and G.S. Huang, J. Electron. Mater. 37, 1742 (2008).

C.L. Chuang, Microelectron. Eng. 84, 559 (2007).

JEDEC Standard, EIA/JESD22-B-116, “Wire Bond Shear Test” (1998).

Y.R. Jeng and J.N. Lin, J. Tribol. 125, 576 (2003).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chuang, CL., Aoh, JN. & Pan, CC. Enhancement of the Bondability and Die-Shear Force of Chip–Flex Substrate Assemblies by Depositing a Nickel Layer on the Flex Substrate. J. Electron. Mater. 41, 2621–2630 (2012). https://doi.org/10.1007/s11664-012-2172-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-012-2172-9