Abstract

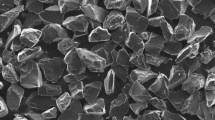

An investigation of the wear behavior, in lubricated sliding and rolling of in situ prepared TiB2 particle-reinforced 2024 T4 Al alloy matrix composites against 52100 steel and hardened pearlitic nodular cast iron, respectively, was undertaken. In sliding contact, the 10 vol pct 0.3-µm TiB2-metal matrix composite (MMC) showed slightly less wear than the 10 vol pct 1.3-µm TiB2-MMC. Transmission electron microscopy of cross sections, taken normal to the wear track and parallel to the sliding direction, revealed that the TiB2 particles on the wear track were polished and particle pullout was largely absent. This was attributed to the strong interfacial bonding between the Al-alloy matrix and the TiB2 reinforcing phase. The TiB2 particles on the wear track inhibited spalling. Subsurface damage of the MMC did not occur. The wear of the steel mating surfaces worn against the TiB2-MMCs was minor and caused by the cutting action of the TiB2 particles that resided on the MMC wear track. In rolling contact, the 0.3-µm-size TiB2-MMC showed 5 times higher weight loss than the 1.3-µm TiB2-MMC for the same content of reinforcement, but the weight loss of the cast iron mating surface was less for the former. For the smaller particle size, the wear of 5 and 10 vol pct TiB2-MMCs was the same. A high density of surface cracks was present on the wear track of the 0.3-µm TiB2-MMC but not on the 1.3-µm MMC. The significance of strong particle/matrix interfacial bonding and particle size effect on the wear behavior of ceramic particulate-reinforced MMCs in lubricated sliding and rolling wear is discussed.

Similar content being viewed by others

References

M.E. Fine: in Recent Advances in Tribology, Y.-W. Chung and H.S. Cheng, eds., Northwestern University, Evanston, IL, 1990.

B.S. Shabel, D.A. Granger, and W.G. Truckner: ASM Handbook, 1992, vol. 18, pp. 785–94.

J.E. Allison and G.S. Cole: J. Met., 1993, vol. 45, pp. 19–24.

K.J. Bhansali and R. Mehrabian: J. Met., 1982, vol. 9, pp. 30–34.

Y.M. Pan: Ph.D. Dissertation, Northwestern University, Evanston, IL, 1990.

M.D. Thouless and A.G. Evans: Acta Metall., 1988, vol. 36, pp. 517–22.

M.E. Fine, D.L. Bourell, Z. Eliezer, C. Persad, and H.L. Markus: Scripta Metall., 1988, vol. 22, pp. 907–10.

T. Iseki, T. Kameda, and T. Maruyama: J. Mater. Sci., 1984, vol. 19, pp. 1692–98.

S.R. Nutt: in Interfaces in Metal Matrix Composites, A.K. Dhingra and S.R. Fishman, eds., TMS-AIME, Warrendale, PA, 1986, pp. 157–67.

D.R. Williams and M.E. Fine: 5th Int. Conf. on Composite Materials ICCM-V, W.C. Harrigan, Jr., J. Strife, and A.K. Dhingra, eds., TMS-AIME, Warrendale, PA, 1985, pp. 639–70.

M.J. Koczak and M.K. Premkumar: J. Met., 1993, vol. 45, pp. 44–48.

J.M. Brupbacher, L. Christodoulou, and D.C. Nagle: U.S. Patent No. 4,710,348, 1987.

L. Christodoulou, D.C. Nagle, and J.M. Brupbacher: U.S. Patent No. 4,751,048, 1988.

L. Christodoulou, D.C. Nagle, and J.M. Brupbacher: U.S. Patent No. 4,716,030, 1990.

R. Mitra, W.A. Chiou, J.R. Weertman, M.E. Fine, and R.M. Aikin, Jr.: Scripta Metall., 1991, vol. 25, pp. 2689–94.

J.F. Braza, H.S. Cheng, M.E. Fine, A.K. Gangopadhyay, L.M. Keer, and R.E. Worden: Tribol. Trans., 1989, vol. 32, pp. 1–8.

J.F. Archard: J. Appl. Phys, 1953, vol. 24, pp. 981–97.

M.M. Kruschchov and M.A. Babichev: Friction Wear Mach., 1956, vol. 11, p. 1.

S.V. Kamat, J.P. Hirth, and R. Mehrabian: Acta Metall., 1989, vol. 37, pp. 2395–2402.

F.M. Hosking, F. Folgar Portillo, R. Wunderlin, and R. Mehrabian: J. Mater. Sci., 1982, vol. 17, pp. 477–98.

Y.M. Pan and H.S. Cheng: Morris E. Fine Symp., P.K. Liaw, J.R. Weertman, H.L. Marcus, and J.S. Santner, eds., TMS-AIME, Warrendale, PA, 1990, pp. 143–51.

J.F. Braza, H.S. Cheng, and M.E. Fine: Scripta Metall., 1987, vol. 21, pp. 1705–10.

R.H. Dauskardt, W. Yu, and R.O. Ritchie: J. Am. Ceram. Soc., 1987, vol. 70, pp. C248-C252.

Y.M. Pan, H.S. Cheng, and M.E. Fine: in Fundamental Relationships between Microstructure and Mechanical Properties of Metal-Matrix Composites, P.K. Liaw and M.N. Gungor, eds., TMS-AIME, Warrendale, PA, 1990, pp. 637–53.

W.R. Brown, N.S. Eiss Jr., and H.T. McAdams: J. Am. Ceram. Soc., 1964, vol. 47, pp. 157–62.

G. Brandt and M. Mikus: Wear, 1987, vol. 115, pp. 243–63.

A.K. Gangopadhyay, M.E. Fine, and H.S. Cheng: Lubr. Eng., 1988, vol. 44, pp. 330–34.

W.O. Winer and H.S. Cheng: in Wear Control Handbook, M.B. Peterson and W.O. Winer, eds., ASME, Fairfield, NJ, 1980, pp. 81–141.

D. Dowson and G.R. Higginson: Elastohydrodynamic Lubrication, SI ed., Pergamon Press, Elmsford, NY, 1977.

J.F. Braza, H.S. Cheng, and M.E. Fine: Tribol. Trans., 1989, vol. 32, pp. 439–46.

J.F. Braza: Ph.D. Dissertation, Northwestern University, Evanston, IL, 1988.

C.Y. Kung and M.E. Fine: Metall. Trans. A, 1979, vol. 10A, pp. 603–10.

D. Lewis III: in Metal Matrix Composites: Processing and Interfaces, R.K. Everett and R.J. Arsenault, eds., Academic Press, New York, NY, 1991, pp. 121–50.

S.M. Mahdavian and Y.W. Mai: Wear, 1984, vol. 95, pp. 35–44.

K.C. Ludema: Wear, 1984, vol. 100, pp. 315–31.

I. Barin: in Thermochemical Data of Pure Substances, VCH Verlagsgesellschaft, Weinheim, Germany, 1989.

A. Erdemir: Lubric. Eng., 1991, vol. 47, pp. 168–73.

A. Erdemir, G.R. Fenske, R.A. Erck, F.A. Nichols, and D.E. Busch: Lubric. Eng., 1991, vol. 47, pp. 179–84.

M.B. Peterson and M. Kanakia: in Engineering Materials for Advanced Friction and Wear Applications, F.A. Smidt and P.J. Blau, eds., ASM, Metals Park, OH, 1988, pp. 153–60.

E.D. Doyle and R.L. Aghan: Metall. Trans. B, 1975, vol. 6B, pp. 143–47.

Y.M. Pan, M.E. Fine, and H.S. Cheng: in Tribology of Composite Materials, P.K. Rohatgi, P.J. Blau, and C.S. Yust, eds., ASM, Materials Park, OH, 1990, pp. 93–101.

R. Mitra, W.A. Chiou, M.E. Fine, and J.R. Weertman: J. Mater. Res., 1993, vol. 8 (9), pp. 2380–92.

J.K. Shang and R.O. Ritchie: Acta Metall., 1989, vol. 37, pp. 2267–78.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Caracostas, C.A., Chiou, W.A., Fine, M.E. et al. Tribological properties of aluminum alloy matrix TiB2 composite prepared by in situ processing. Metall Mater Trans A 28, 491–502 (1997). https://doi.org/10.1007/s11661-997-0150-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-997-0150-2