Abstract

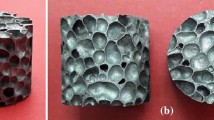

Low-density closed-cell aluminum foam is promising to be used as load-bearing and thermal insulation components. It is necessary to systematically study its thermal expansion performance. In this work, linear thermal expansion coefficient (LTEC) of the closed-cell aluminum foam of different density was measured in the temperature range of 100–500 °C. X-ray fluorescence was used to analyze elemental composition of the cell wall material. Phase transition characteristics were analyzed with X-ray diffraction and differential scanning calorimetry. LTEC of the closed-cell aluminum foam was found to be dominated by its cell wall property and independent of its density. Particularly, two anomalies were found and experimentally analyzed. Due to the release of the residual tensile stress, the LTEC declined and even exhibited negative values. After several thermal cycles, the residual stress vanished. With temperature higher than 300 °C, instantaneous LTEC showed hysteresis, which should result from the redistribution of some residual hydrogen in the Ti2Al20Ca lattice.

Similar content being viewed by others

References

Ashby MF, Evans T, Fleck NA et al (2000) Metal foams: a design guide. Butterworth-Heinemann, UK

Banhart J (2001) Manufacture, characterisation and application of cellular metals and metal foams. Prog Mater Sci 46:559–632

Lu TJ, Zhang QC (2009) Development of multifunctional lightweight cellular metals through interdisciplinary efforts. Chin Sci Bull 54:3844–3846

Nieh TG, Higashi K, Wadsworth J (2000) Effect of cell morphology on the compressive properties of open-cell aluminum foams. Mat Sci Eng A Struct 283:105–110

Lu TJ, Ong JM (2001) Characterization of close-celled cellular aluminum alloys. J Mater Sci 36:2773–2786

Markaki AE, Clyne TW (2001) The effect of cell wall microstructure on the deformation and fracture of aluminium-based foams. Acta Mater 49:1677–1686

Benouali AH, Froyen L, Dillard T et al (2005) Investigation on the influence of cell shape anisotropy on the mechanical performance of closed cell aluminium foams using micro-computed tomography. J Mater Sci 40:5801–5811

Raj RE, Daniel BSS (2009) Structural and compressive property correlation of closed-cell aluminum foam. J Alloy Compd 467:550–556

Onck P, Van Merkerk R, Raaijmakers A et al (2005) Fracture of open- and closed-cell metal foams. J Mater Sci 40:5821–5828

Jeon I, Katou K, Sonoda T et al (2009) Cell wall mechanical properties of closed-cell Al foam. Mech Mater 41:60–73

Lu TJ, Chen C (1999) Thermal transport and fire retardance properties of cellular aluminium alloys. Acta Mater 47:1469–1485

Coquard R, Baillis D (2009) Numerical investigation of conductive heat transfer in high-porosity foams. Acta Mater 57:5466–5479

Fiedler T, Solórzano E, Garcia-Moreno F et al (2009) Lattice Monte Carlo and experimental analyses of the thermal conductivity of random-shaped cellular aluminum. Adv Eng Mater 11:843–847

Fiedler T, Solórzano E, Garcia-Moreno F et al (2009) Computed tomography based finite element analysis of the thermal properties of cellular aluminium. Materialwiss Werkst 40:139–143

Veyhl C, Belova IV, Murch GE et al (2011) Thermal analysis of aluminium foam based on micro-computed tomography. Materialwiss Werkst 42:350–355

Paek JW, Kang BH, Kim SY et al (2000) Effective thermal conductivity and permeability of aluminum foam materials. Int J Thermophys 21:453–464

Babcsan N, Meszaros I, Hegman N (2003) Thermal and electrical conductivity measurements on aluminum foams. Materialwiss Werkst 34:391–394

Solorzano E, Rodriguez-Perez MA, Reglero JA et al (2007) Density gradients in aluminium foams: characterisation by computed tomography and measurements of the effective thermal conductivity. J Mater Sci 42:2557–2564

Sadeghi E, Hsieh S, Bahrami M (2011) Thermal conductivity and contact resistance of metal foams. J Phys D Appl Phys 44:125406–125412

Lázaro J, Escudero J, Solórzano E et al (2009) Heat transport in closed cell aluminum foams: application notes. Adv Eng Mater 11:825–831

Kitazono K, Sato E, Kuribayashi K (2003) Application of mean-field approximation to elastic-plastic behavior for closed-cell metal foams. Acta Mater 51:4823–4836

Hosseini SMH, Kharaghani A, Kirsch C et al (2011) Numerical investigation of the thermal properties of irregular foam structures. In: Ochsner A, Murch GE, Delgado JMP (eds) Diffusion in solids and liquids Vi, Pts 1 and 2, vol 312–315. Trans Tech Publications, Switzerland, pp 941–946

Miyoshi T, Itoh M, Akiyama S et al (2000) ALPORAS aluminum foam: production process, properties, and applications. Adv Eng Mater 2:179–183

Almanza O, Masso-Moreu Y, Mills NJ et al (2004) Thermal expansion coefficient and bulk modulus of polyethylene closed-cell foams. J Polym Sci Pol Phys 42:3741–3749

Huang YD, Hort N, Dieringa H et al (2005) Analysis of instantaneous thermal expansion coefficient curve during thermal cycling in short fiber reinforced AlSi12CuMgNi composites. Compos Sci Technol 65:137–147

Chen N, Zhang H, Gu M et al (2009) Effect of thermal cycling on the expansion behavior of Al/SiCp composite. J Mater Process Tech 209:1471–1476

Simone AE, Gibson LJ (1998) Aluminum foams produced by liquid-state processes. Acta Mater 46:3109–3123

Byakova A, Gnyloskurenko S, Nakamura T (2012) The role of foaming agent and processing route in the mechanical performance of fabricated aluminum foams. Metals 2:95–112

Wang R (1985) Physical properties of metal materials. Metallurgical Industry Press, Beijing

Lu XS (1990) Phase diagram and phase transition. USTC Press, Hefei

Sorokina NI, Wlocewicz D, Plackowcki T (1996) Phase transitions in Nb-H system. Int J Hydrog Energy 21:939–943

Plackowski T, Sorokina NI, Wlosewicz D (1998) Order-disorder phase transitions in NbH0.86. J Phys-condens Mat 10:1259

Welter JM, Schondube F (1983) A resistometric and neutron diffraction investigation of the Nb-H system at high hydrogen concentrations. J Phys F Metal Phys 13:529

Nakamura Y, Bowman RC Jr, Akiba E (2007) Variation of hydrogen occupation in LaNi4.78Sn0.22D x along the P-C isotherms studied by in situ neutron powder diffraction. J Alloy Compd 431:148–154

Bau R, Teller RG, Kirtley SW et al (1979) Structures of transition-metal hydride complexes. Acc Chem Res 12:176–183

Acknowledgments

This work was supported by the National Natural Science Foundation of China (90916026). The authors would like to thank Guien Zhou, Guanyin Gao, Yanwei Ding and Shiding Zhang for their supports in the XRD, DSC and XRF analyses.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Ye, H., Ma, M. & Yu, J. Anomalies in mid-high-temperature linear thermal expansion coefficient of the closed-cell aluminum foam. Chin. Sci. Bull. 59, 3669–3675 (2014). https://doi.org/10.1007/s11434-014-0508-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11434-014-0508-y