Abstract

Introduction

In this series of papers, we present a poly(methyl methacrylate) (PMMA) recycling system design based on environmental impacts, chemical hazards, and resource availability. We evaluated the recycling system by life cycle assessment, environment, health, and safety method, and material flow analysis.

Purpose

Previous recycling systems have not focused on highly functional plastics such as PMMA, partly because of lower available volumes of waste PMMA compared with other commodity plastics such as polyethylene or polypropylene. However, with the popularization of PMMA-containing products such as liquid crystal displays, the use of PMMA is increasing and this will result in an increase in waste PMMA in the future. The design and testing of recycling systems and technologies for treating waste PMMA is therefore a high research priority. In this study, we analyze recycling of PMMA monomers under a range of scenarios.

Methods

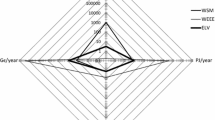

Based on the differences between PMMA grades and their life cycles, we developed a life cycle model and designed a range of scenarios for PMMA recycling. We obtained monomer recycling process inventory data based on the operational results of a pilot plant. Using this process inventory data, we quantified life cycle greenhouse gas (LC-GHG) emissions and fossil resource consumption, and we calculated the LIME single index.

Results and discussion

PMMA produces more than twice the amount of GHG emissions than other commodity resins. Through scenario and sensitivity analyses, we demonstrated that monomer recycling is more effective than mechanical recycling. Operational modifications in the monomer recycling process can potentially decrease LC-GHG emissions.

Conclusions

Highly functional plastics should be recycled while maintaining their key functions, such as the high transparency of PMMA. Monomer recycling has the potential to achieve a closed-loop recycling of PMMA.

Similar content being viewed by others

Abbreviations

- BHET:

-

Bis(hydroxylethyl) terephthalate

- CR:

-

Chemical recycling

- DMT:

-

Dimethyl terephthalate

- HEA:

-

Home electrical appliances

- H-sheet:

-

High molecular weight PMMA sheet

- LIME:

-

Japanese life-cycle impact assessment method based on endpoint modeling

- LGP:

-

Light guide panel

- L-pellet:

-

Low molecular weight PMMA pellet

- L-sheet:

-

Low molecular weight PMMA sheet

- MMA:

-

Methyl methacrylate

- MR:

-

Material recycling (mechanical recycling)

- OAE:

-

Office automation equipment

- PE:

-

Polyethylene

- PET:

-

Polyethylene terephthalate

- PMMA:

-

Poly(methyl methacrylate)

- PP:

-

Polypropylene

- PS:

-

Polystyrene

- PTA:

-

Purified terephthalic acid

- RPF:

-

Refused plastic/paper fuel

- TR:

-

Thermal recycling (thermal recovery)

References

Achilias DS (2007) Chemical recycling of poly(methyl methacrylate) by pyrolysis. Potential use of the liquid fraction as a raw material for the reproduction of the polymer. Eur Polym J 43:2564–2575

Andrae ASG (2009) Global life cycle impact assessments of material shifts: the example of a lead-free electronics industry. Springer, London

Andrae ASG, Andersen O (2010) Life cycle assessments of consumer electronics—are they consistent? Int J Life Cycle Assess 15:827–836

Arena U, Mastellone ML, Perugini F (2003a) The environmental performance of alternative solid waste management options: a life cycle assessment study. Chem Eng J 96:207–222

Arena U, Mastellone ML, Perugini F (2003b) Life cycle assessment of a plastic packaging recycling system. Int J Life Cycle Assess 8(2):92–98

Biegler LT, Grossmann IE, Westerberg AW (1997) Systematic methods of chemical process design. Prentice Hall, New Jersey

Clift R (1997) Clean technology—the idea and the practice. J Chem Tech Biotechnol 68:347–350

Display Search Ltd (2012) LCD TV shipments to grow 7% in 2012 to 220M units, despite zero growth in overall TV shipments. http://www.displaysearch.com/cps/rde/xchg/displaysearch/hs.xsl/120509_lcd_tv_shipments_to_grow_in_2012_to_220M_units_despite_zero_growth_in_overall_tv_shipments.asp. Accessed 26 May 2012

Dodbiba G, Takahashi K, Sadaki J, Fujita T (2008) The recycling of plastic wastes from discarded TV sets: comparing energy recovery with mechanical recycling in the context of life cycle assessment. J Clean Prod 16:458–470

Fujii M, Fujita T, Chen X, Ohnishi S, Yamaguchid N (2012) Smart recycling of organic solid wastes in an environmentally sustainable society. Resour Conserv Recycl 63:1–8

Hirasawa E (1999) A recycling plant for home electric appliances. Mitsubishi Electr Adv 87:7–11

Hischier R, Baudin I (2010) LCA study of a plasma television device. Int J Life Cycle Assess 15:428–438

Humbert S, Rossi V, Margni M, Jolliet O, Loerincik Y (2009) Life cycle assessment of two baby food packaging alternatives: glass jars vs. plastic pots. Int J Life Cycle Assess 14:95–106

Iosif AM, Hanrot F, Birat JP, Ablitzer D (2010) Physicochemical modeling of the classical steelmaking route for life cycle inventory analysis. Int J Life Cycle Assess 15:304–310

Japan Environmental Management Association for Industry (JEMAI) (2007) LCA software JEMAI-LCA Pro, Japan Environmental Management Association for Industry (JEMAI)

Japan Petrochemical Industry Association (JPIA) (2012) Statistical data of MMA production, shipment, and stock. http://www.jpca.or.jp/4stat/00index.htm. Accessed 21 May 2012

Kaminsky W, Franck J (1991) Monomer recovery by pyrolysis of poly (methyl methacrylate) (PMMA). J Anal Appl Pyrol 19:311–318

Kikuchi Y, Hirao M (2009) Hierarchical activity model for risk-based decision making integrating life cycle and plant-specific risk assessments. J Ind Ecol 13(6):945–964

Life Cycle Assessment Society of Japan (JLCA) (2012) JLCA-LCA database 2012, 1st edn. Life Cycle Assessment Society of Japan (JLCA), Tokyo

Lopez G, Artetxe M, Amutio M, Elordi G, Aguado R, Olazar M, Bilbao J (2010) Recycling poly-(methyl methacrylate) by pyrolysis in a conical spouted bed reactor. Chem Eng Process 49:1089–1094

Mayumi K, Kikuchi Y, Nakatani J, Hirao M (2010) Decision support for plastics recycling system design based on individual fossil resource consumption. KagakuKogakuRonbunshu 36(4):243–254

Mendivil R, Fischer U, Hirao M, Hungerbühler K (2006) A new LCA methodology of technology evolution (TE-LCA) and its application to the production of ammonia (1950–2000). Int J Life Cycle Assess 11(2):98–105

Ministry of Economy, Trade and Industry, Japan (METI) (2001) Home Appliance Recycling Act. http://www.meti.go.jp/policy/recycle/main/english/law/home.html. Accessed 21 May 2012

Ministry of Economy, Trade and Industry, Japan (METI) and Mitsubishi Rayon Co., Ltd. (MRC) (2008) Development of energy saving technology for acrylic resin production: a recycling process of poly (methyl methacrylate) into methyl methacrylate monomer for industrialization (original title in Japanese). http://www.meti.go.jp/policy/tech_evaluation/c00/C0000000H20/081110_fiber/fiber08-5-2.pdf. Accessed 25 Apr 2013

Ministry of Economy, Trade and Industry, Japan (METI) (2012) Paper, printing, plastic, rubber products statistics. http://www.meti.go.jp/statistics/tyo/seidou/result/ichiran/06_kami.html. Accessed 21 May 2012

Mitsubishi Rayon Co., Ltd. (MRC) (2011) Device and method of pyrolysis of resin (original title in Japanese), P2011-236337A: 24 Nov 2011

Nakagawa K (2007) Monomer recycling of acrylic resin (original title in Japanese). The 66th Conference of the Committee of Polymer Processing in The Japan Society for Technology of Plasticity, Toyama

Nakano K, Aoki R, Yagita H, Narita N (2007) Evaluating the reduction in green house gas emissions achieved by the implementation of the household appliance recycling in Japan. Int J Life Cycle Assess 12(5):289–298

Nakatani J, Hirao M (2011) Multicriteria design of plastic recycling based on quality information and environmental impacts. J Ind Ecol 15(2):228–244

Nakatani J, Fujii M, Moriguchi Y, Hirao M (2010) Life-cycle assessment of domestic and transboundary recycling of post-consumer PET bottles. Int J Life Cycle Assess 15:590–597

Nakatani J, Okuno A, Fujii M, Hirao M (2011) Life-cycle assessment of material recycling based on market substitutability: a case study of PET bottle recycling. J Life Cycle Assess Jpn 7(1):96–107

Nguyen T, Sugiyama H, Noda M, Hirao M (2009) Structural framework supporting selection of extraction processes under sustainable criteria. J Chem Eng Jpn 43(1):186–195

PC3R Promotion Association, Japan (2003) http://www.pc3r.jp/e/index.html. Accessed 31 May 2012

Perugini F, Mastellone ML, Arena U (2005) A life cycle assessment of mechanical and feedstock recycling options for management of plastic packaging wastes. Environ Prog 24(2):137–154

Plastic Waste Management Institute, Japan (PWMI) (2009) Investigation report on LCI data of petrochemical products (original title in Japanese). Plastic Waste Management Institute, Japan (PWMI), Tokyo

Plastic Waste Management Institute, Japan (PWMI) (2010) Plastic recycling flow sheet in Japan (original title in Japanese). http://www2.pwmi.or.jp/siryo/flow/flow_pdf/flow2009.pdf. Accessed 21 May 2012

Plastics Europe (2011) Plastics—the facts 2010. http://www.plasticseurope.org/plastics-industry/market-data.aspx. Accessed 21 May 2012

Ribeiro C, Ferreira JV, Partidário P (2006) Life cycle assessment of a multi-material car component. Int J Life Cycle Assess 12(5):336–345

Romero-Hernández O, Romero-Hernández S, Muñoz D, Detta-Silveira E, Palacios-Brun A, Laguna A (2009) Environmental implications and market analysis of soft drink packaging systems in Mexico. A waste management approach. Int J Life Cycle Assess 14(2):107–113

Sasaki A (2008) A closed recycling technology for acrylic resin. J Energy Technol Intell 56(14):26–29

Sasaki A, Kikuya N, Ookubo T, Hayashida M (2008) Recovery method of pyrolysis product of resin, PCT/JP2008/054153: 3 September 2009 (WO2008/108461:12 September 2008)

Scheirs J, Kaminsky W (eds) (2006) Feedstock recycling and pyrolysis of waste plastics: converting waste plastics into diesel and other fuels (Wiley Series in Polymer Science). John Wiley & Sons, Chichester

Shena L, Worrellb E, Patela MK (2010) Open-loop recycling: a LCA case study of PET bottle-to-fibre recycling. Resour Conserv Recycl 55:34–52

Shimada M, Miyamoto K, Hirao M, Nakamura T (2005) Life cycle inventory and cost analysis of waste plastics utilization in the steel industry. Tetsu-to-Hagane 91(1):184–191

Sinha V, Patel MR, Patel JV (2010) Pet waste management by chemical recycling: a review. J Polym Environ 18:8–25

Sugiyama H, Hirao M, Mendivil R, Fischer U, Hungerbühler K (2006) A hierarchical activity model of chemical process design based on life cycle assessment. Process Saf Environ Prot 84(B1):63–74

The Japan Containers and Packaging Recycling Association (JCPRA) (2007) Investigation on environmental loads of recycling methods for plastic containers and packaging in Japan. http://www.jcpra.or.jp/00oshirase/pdf/lca_kanzen.pdf. Accessed 21 May 2012

The Japan Plastics Industry Federation (JPIF) (2012) http://www.jpif.gr.jp/3toukei/conts/2011/2011_genryou_c.htm. Accessed 21 May 2012

Trambouze P (2000) Petroleum refining, 4th volume: materials and equipment. Technip, Paris

Yamasue E, Minamino R, Daigo I, Okumural H, Ishihara KN (2009) Evaluation of total materials requirement for the recycling of elements and materials (urban ore TMR) from end-of-life electric home appliances. Mater Trans 50(9):2165–2172

Acknowledgments

The authors thank Tran Nghiep Nam, Takahiro Izumi, Emiri Kakazu, Akira Sasaki, and Genya Tanaka for their cooperation in data collection for LCA. Part of this study was supported by a Grant-in-Aid for Scientific Research (B) (no. 23360404) from the Japan Society for the Promotion of Science.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Yasunari Matsuno

Rights and permissions

About this article

Cite this article

Kikuchi, Y., Hirao, M., Ookubo, T. et al. Design of recycling system for poly(methyl methacrylate) (PMMA). Part 1: recycling scenario analysis. Int J Life Cycle Assess 19, 120–129 (2014). https://doi.org/10.1007/s11367-013-0624-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-013-0624-y