Abstract

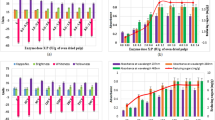

In this study, suitability of xylano-pectinolytic enzymes in pulping of wheat straw has been explored. The suitable biopulping conditions were optimized, with xylanase dose of 400 and pectinase dose of 120 IU/g wheat straw, 1:10 (g/ml) material to liquid ratio, 55 °C temperature, 3 h treatment time, 0.75% Tween 80 and pH 8.5. Enzymatic pretreatment efficiently increased the pulpability of wheat straw, generated pulp with higher yield, lower kappa number (15.67%) and rejections (59.65%) in comparison with chemical pulp. The brightness of pretreated wheat straw pulp with enzyme was 16.04% higher than that of the non-enzyme treated wheat straw pulp. The biopulping resulted in 12% reduction of pulping chemicals along with more residual alkali content, in order to achieve similar optical and chemical properties as obtained by 100% chemically treated pulp. Physical properties of pulp also improved after enzymatic pretreatment, increasing burst index (26.50%), tear index (18.22%) and breaking length (5.56%). The enzyme plus chemical (88% pulping chemicals) treated pulp showed improvement in brightness and whiteness, with reduction in yellowness at all bleaching stages. In comparison with chemically bleached pulp, biopulp with reduced alkali dose (88%) had higher breaking length (6.63%), double fold number (51.28%), tear index (2.83%), burst index (24.31%), along with increased viscosity (6.12%) and Gurley porosity (27.50%). These results clearly suggest that biopulping of wheat straw with xylano-pectinolytic enzymes can reduce chemical loading during soda-anthraquinone pulping and also improve the quality of paper. This is the first report demonstrating the biopulping of wheat straw using crude xylano-pectinolytic enzymes.

Similar content being viewed by others

References

Ayyachamy M, Vatsala TM (2007) Production and partial characterization of cellulase free xylanase by Bacillus subtilis C 01 using agriresidues and its application in biobleaching of nonwoody plant pulps. Lett Appl Microbiol 45(5):467–472

Carvalheiro F, Silva-Fernandes T, Duarte LC, Gírio FM (2009) Wheat straw autohydrolysis: process optimization and products characterization. Appl Biochem Biotechnol 153(1–3):84–93

Fang G, Shen K (2018) Wheat straw pulping for paper and paperboard production. In Global wheat production (Fahad S, Basir A and Adnan M), 223-239. https://doi.org/10.5772/intechopen.77274

Hise R (1996) Chlorination. In: Dence CW, Reeve DW (eds) Pulp bleaching–principles and practice. Tappi Press Atlanta, Georgia, pp 241–259

Kaur A, Mahajan R, Singh A, Garg G, Sharma J (2010) Application of cellulase-free xylano-pectinolytic enzymes from the same bacterial isolate in biobleaching of kraft pulp. Bioresour Technol 101(23):9150–9155

Kaur A, Singh A, Dua A, Mahajan R (2017) Cost-effective and concurrent production of industrially valuable xylano-pectinolytic enzymes by a bacterial isolate Bacillus pumilus AJK. Prep Biochem Biotechnol 47(1):8–18

Khandeparkar R, Bhosle NB (2007) Application of thermoalkalophilic xylanase from Arthrobacter sp. MTCC 5214 in biobleaching of kraft pulp. Bioresour Technol 98(4):897–903

Liu X, Jiang Y, Yang S, Meng X, Song X, Wu M (2017a) Effects of pectinase treatment on pulping properties and the morphology and structure of bagasse fiber. BioResources 12(4):7731–7743

Liu X, Jiang Y, Xie Q, Nie S, Song X (2017b) Effect of alkali pectinase pretreatment on bagasse soda-anthraquinone pulp. BioResources 12(3):5045–5056

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Patel RN, Grabski AC, Jeffries TW (1993) Chromophore release from kraft pulp by purified Streptomyces roseiscleroticus xylanases. Appl Microbiol Biotechnol 39:405–412

SCAN-C 19:65 (1999) Pulps determination of drainability-part 1 (Schopper-Riegler method)

Segura TES, Dos Santos JRS, Sarto C, Da Silva Jr FG (2016) Effect of kappa number variation on modified pulping of eucalyptus. BioResources 11(4):9842–9855

TAPPI T205 sp-02 (2002) Forming handsheets for physical tests of pulp. TAPPI Press, Atlanta

TAPPI T217 wd-77 (2004) Brightness of pulp. TAPPI Press, Atlanta

TAPPI T230 om-99 (1976) Viscosity of pulp (capillary viscometer method). TAPPI Press, Atlanta

TAPPI T236 om-99 (2004) Kappa number of pulp. TAPPI Press, Atlanta

TAPPI T403 om-10 (2010) Burst strength of paper. TAPPI Press, Atlanta

TAPPI T414 om-04 (2004) Internal tearing resistance of paper (Elmendorf-type method). TAPPI Press, Atlanta

TAPPI T460 om-02 (2002) Air resistance of paper. TAPPI Press, Atlanta

TAPPI T494 om-01 (2001) Tensile breaking properties of paper and paperboard. TAPPI Press, Atlanta

TAPPI T511 om-02 (2002) Folding endurance of paper (MIT tester). TAPPI Press, Atlanta

TAPPI T625 cm-14 (2014) Analysis of soda and sulfate black liquor. TAPPI Press, Atlanta

Verma D, Satyanarayana T (2013) Production of cellulase-free xylanase by the recombinant Bacillus subtilis and its applicability in paper pulp bleaching. Biotechnol Prog 29(6):1441–1447

Woldesenbet F, Virk AP, Gupta N, Sharma P (2012) Effect of microwave irradiation on xylanase production from wheat bran and biobleaching of eucalyptus kraft pulp. Appl Biochem Biotechnol 167(1):100–108

Funding

The authors thankfully acknowledge the financial support provided by Department of Biotechnology (DBT), Ministry of Science & Technology, Government of India (Grant Number: BT/PR 20438/BCE/8/1220/2016 for 3 years). The corresponding author is also thankful to Avantha Center for Industrial Research and Development (ACIRD), Yamuna Nagar, for providing their laboratory facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Varghese, L.M., Agrawal, S., Nagpal, R. et al. Eco-friendly pulping of wheat straw using crude xylano-pectinolytic concoction for manufacturing good quality paper. Environ Sci Pollut Res 27, 34574–34582 (2020). https://doi.org/10.1007/s11356-020-10119-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-10119-1