Abstract

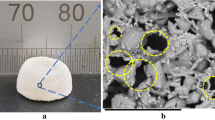

This work deals with the fabrication and mechanical improvement of nanostructured forsterite foam. Nanostructured forsterite foams were prepared via gelcasting followed by two step sintering. Phase composition, morphology, porosity and compressive strength of the sintered foams were evaluated by X-ray diffractometry, scanning electron microscopy, Archimedes method, and compression tests. In addition, the in vitro bioactivity of forsterite foams was evaluated by soaking the samples in simulated body fluid. Results showed that nanostructured forsterite foams were prepared with maximum compressive strength and elastic modulus of about 7.2 and 271 MPa, respectively. The foams had highly interconnected spherical pores with size in the range of 60–320 μm. Total porosity of the prepared foams was in the range of 79–87 %, which depends on the heat treatment process. During immersion in simulated body fluid, apatite layer was formed on nanostructured forsterite foam, which proved the good bioactivity of the prepared foam. It was concluded that two step sintering can prepare highly porous foams with appropriate compressive strength for tissue engineering applications.

Graphical Abstract

Similar content being viewed by others

References

Kharaziha M, Fathi MH (2010) Improvement of mechanical properties and biocompatibility of forsterite bioceramic addressed to bone tissue engineering materials. J Mech Behav Biomed Mater 3:530–537

Padmanabhann SK, Gervaso F, Carrozzo M, Scalera F, Sannino A, Licciulli A (2013) Wollastonite/hydroxyapatite scaffolds with improved mechanical, bioactive and biodegradable properties for bone tissue engineering. Ceram Int 39:1–9

Tavangarian F, Emadi R (2011) Improving degradation rate and apatite formation ability of nanostructure forsterite. Ceram Int 37:2275–2280

Fathi MH, Kharaziha M (2008) Mechanochemical synthesis and characterization of nanostructure forsterite bioceramics. Int J Mod Phys B 22:3082–3091

Naghiu MA, Gorea M, Mutch E, Kristaly F, Tomoaia-Cotisel M (2013) Forsterite nanopowder: structural characterization and biocompatibility evaluation. J Materials Sci Technol 29:628–632

Diba M, Fathi MH, Kharaziha M (2011) Novel forsterite/polycaprolactone nanocomposite scaffold for tissue engineering applications. Mater Lett 65:1931–1934

Ghomi H, Jaberzadeh M, Fathi MH (2011) Novel fabrication of forsterite scaffold with improved mechanical properties. J Alloy Compd 509:63–68

Tavangarian F, Emadi R (2011) Nanostructure effects on the bioactivity of forsterite bioceramic. Mater Lett 65:740–743

Fathi MH, Kharaziha M (2009) Two-step sintering of dense, nanostructural forsterite. Mater Lett 63:1455–1458

Cullity BD (1978) Elements of X-ray diffraction. Addison-Wesley, Windsor Locks, CT

Bohner M, Lemaitre J (2009) Can bioactivity be tested in vitro with SBF solution? Biomaterials 30:2175–2179

Ramay HR, Zhang M (2003) Preparation of porous hydroxyapatite scaffolds by combination of the gel-casting and polymer sponge methods. Biomaterials 24:3293–3302

Bellucci D, Cannillo V, Sola A (2011) A new potassium-based bioactive glass: sintering behaviour and possible applications for bioceramic scaffolds. Ceram Int 37:145–157

Fu Q, Saiz E, Rahaman MN, Tomsia AP (2011) Bioactive glass scaffolds for bone tissue engineering: state of the art and future perspectives. Mater Sci Eng 31:1245–1256

Lopes JH, Magalhães JA, Gouveia RF, Bertran CA, Motisuke M, Camargo SEA, Tricheˆs ES (2016) Hierarchical structures of β-TCP/45S5 bioglass hybrid scaffolds prepared by gelcasting. J Mech Behav Biomed Mater 62:10–23

Li JJ, Gil ES, Hayden RS, Li C, Roohani Esfahani SI, Kaplan DL, Zreiqat H (2013) Multiple silk coatings on biphasic calcium phosphate scaffolds: effect on physical and mechanical properties, and in vitro osteogenic response of human mesenchymal stem cells. Biomacromolecules 14:2179–2188

Ghomi H, Fathi MH, Edris H (2012) Effect of the composition of hydroxyapatite/bioactive glass nanocomposite foams on their bioactivity and mechanical properties. Mater Res Bull 47:3523–3532

Kim JH, Lee JH, Yang TY, Yoon SY, Kim BK, Park HC (2011) TBA-based freeze/gel casting of porous hydroxyapatite foams. Ceram Int 37:2317–2322

Tripathi G, Basu B (2012) A porous hydroxyapatite scaffold for bone tissue engineering: physico-mechanical and biological evaluations. Ceram Int 38:341–349

Mirhadi SM (2014) Synthesis and characterization of nanostructured forsterite scaffolds using two step sintering method. J Alloy Compd 610:399–401

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Saidi, R., Fathi, M., Salimijazi, H. et al. Fabrication and characterization nanostructured forsterite foams with high compressive strength, desired porosity and suitable bioactivity for biomedical applications. J Sol-Gel Sci Technol 81, 734–740 (2017). https://doi.org/10.1007/s10971-016-4240-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-016-4240-8