Abstract

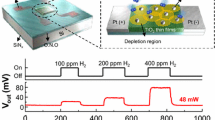

Metal oxide based gas sensors are usually read-out by measuring the overall resistivity of the gas sensitive layer. However, the reaction of the gas species with the metal oxide surface does not only change the electrical conductivity but also effects the required heating power to maintain the layer’s temperature. This change in power consumption may be disregarded when using standard bulk sensor chips due to their overall high thermal mass. Nevertheless, micromachined Si based hotplate devices offer the possibility to measure these effects. Here we present results that have been obtained by using a novel hotplate platform optimized for low power consumption and inkjet printing of nano sized gas sensitive metal oxide particles. The temperature of the gas sensitive layer is controlled via the heater resistance and the power consumption is recorded with a fully automated gas measurement system. To separate changes in the heat conductivity of the gas matrix from the heat of the surface reaction, the measurements have been performed in parallel using hotplates with and without a metal oxide layer deposited onto them. Here layers composed of copper (II) oxide have been used to highlight the possibilities of the novel approach. Determining both, the gas dependent resistivity as well as heating power yields two independent sensing quantities from one single device and might be an important cornerstone on the way towards selective metal oxide based gas sensors.

Similar content being viewed by others

References

Barsan N, Simion C, Heine T, Pokhrel S, Weimar U (2010) Modeling of sensing and transduction for p-type semiconducting metal oxide based gas sensors. J Electroceram 25:11–19

Buttner WJ, Post MB, Burgess R, Rivkin C (2011) An overview of hydrogen safety sensors and requirements. Int J Hydrog Energy 36(3):2462–2470

Chen A, Long H, Li X, Li Y, Yang G, Lu P (2009) Controlled growth and characteristics of single-phase Cu2O and CuO films by pulsed laser deposition. Vacuum 83(6):927–930

Chowdhuri A, Gupta V, Sreenivas K, Kumar R, Mozumdar S, Patanjal PK (2004) Response speed of SnO2—based H2S gas sensors with CuO nanoparticles. Appl Phys Lett 84:1180

Datasheet Fujifilm Dimatix DMP-2800 (2013). http://www.fujifilmusa.com/shared/bin/PDS00085-DMP2831.pdf. Date of access 30 Mar 2015

Espinos JP, Morales J, Barranco A, Caballero A, Holgado JP, Gonzalez-Elipe AR (2002) Interface effects for Cu, CuO, and Cu2O deposited on SiO2 and ZrO2. XPS determination of the valence state of copper in Cu/SiO2 and Cu/ZrO2 catalysts. J Phys Chem B 106:6921–6929

Frietsch M, Zudock F, Goschnick J, Bruns M (2000) CuO catalytic membrane as selectivity trimmer for metal oxide gas sensors. Sensors Actuators B Chem 65:379–381

Heiland G (1954) Zum Einfluß von adsorbiertem Sauerstoff auf die elektrische Leitfähigkeit von Zinkoxydkristallen. Zeitschrift für Physik 138(3–4):459–464

Kneer J, Wöllenstein J, Palzer S (2014a) Specific, trace gas induced phase transition in copper(II)oxide for highly selective gas sensing. Appl Phys Lett 105:073509

Kneer J, Eberhardt A, Walden P, Ortiz Pérez A, Wöllenstein J, Palzer S (2014b) Apparatus to characterize gas sensor response under real-world conditions in the lab. Rev Sci Instrum 85:055006

Kneer J, Knobelspies S, Bierer B, Wöllenstein J, Palzer S (2016) New method to selectively determine hydrogen sulfide concentrations using CuO layers. Sensors Actuators B Chem 222:625–631

Leitner J, Sedmidubsky D, Dousova B, Strejc A, Nevriva M (2000) Heat capacity of CuO in the temperature range of 298.15-1300 K. Thermochim Acta 1–2:49–51

Lemmon EW, Jacobsen RT (2004) Viscosity and thermal conductivity equations for nitrogen, oxygen, argon, and air. Int J Thermophys 25(1):21–69

Li Y, Liang J, Tao Z, Chen J (2008) CuO particles and plates: synthesis and gas-sensor application. Mater Res Bull 43(8–9):2380–2385

Morales J, Sánchez L, Martín F, Ramos-Barrado JR, Sánchez M (2005) Use of low-temperature nanostructured CuO thin films deposited by spray-pyrolysis in lithium cells. Thin Solid Films 474(1–2):133–140

Morrison SR (1987) Selectivity in semiconductor gas sensors. Sensors and Actuators 12:425–440

Petersen H (1970) The properties of helium: density, specific heats, viscosity, and thermal conductivity at pressures from 1 to 100 bar and from room temperature to about 1800 K. In: Riso Report No. 224

Sahner K, Tuller HL (2010) Novel deposition techniques for metal oxide: prospects for gas sensing. J Electroceram 24:77–199

Shanks HR, Maycock PD, Sidles PH, Danielson GC (1963) Thermal conductivity of silicon from 300 to 1400°K. Phys Rev 130:1743

Volanti DP, Felix AA, Orlandi MO, Whitfield G, Yang D-J, Longo E, Tuller HL, Varela JA (2013) The role of hierarchical morphologies in the superior gas sensing performance of CuO-based chemiresistors. Adv Funct Mater 23:1759–1766

Walden P, Kneer J, Knobelspies S, Kronast W, Mescheder U, Palzer S (2015) Micromachined hotplate platform for the investigation of ink-jet printed, functionalized metal oxide nanoparticles. J Microelectromech 24(5):1384–1390

Westrum EF, Stolen S, Gronvold F (1987) Thermodynamics of copper sulfides II. Heat capacity and thermodynamic properties of synthetic covellite, CuS, from 5 to 780.5 K. Enthalpy of decomposition. J Chem Thermodyn 19:1199–1208

Williams DE (1999) Semiconducting oxides as gas-sensitive resistors. Sensors Actuators B Chem 57(1–16):1–3

Yamazoe N (1991) New approaches for improving semiconductor gas sensors. Sensors Actuators B 5:7–19

Yuanda W, Maosong T, Xiuli H, Yushu Z, Guorui D (2001) Thin film sensors of SnO2-CuO-SnO2 sandwich structure to H2S. Sensors Actuators B Chem 79(2–3):187–191

Zhang F, Zhu A, Luo Y, Tian Y, Yang J, Qin Y (2010) CuO nanosheets for sensitive and selective determination of H2S with high recovery ability. J Phys Chem C 114(45):19214–19219

Acknowledgments

This work was supported by a Grant from the German Federal ministry of Science and Education (BMBF) under Grant Number 16SV5943 (SensOdor). B.B. acknowledges funding by the graduate school “decentralized, sustainable energy systems (DENE)”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bierer, B., Kneer, J., Wöllenstein, J. et al. MEMS based metal oxide sensor for simultaneous measurement of gas induced changes of the heating power and the sensing resistance. Microsyst Technol 22, 1855–1863 (2016). https://doi.org/10.1007/s00542-016-2862-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00542-016-2862-y