Abstract

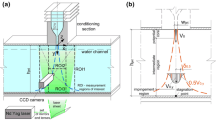

The current study focuses on experimentally and theoretically improving the characterization of the drop size and drop velocity for like-on-like doublet impinging jets. The experimental measurements were made using phase Doppler anemometry (PDA) at jet Weber numbers We j corresponding to the impact wave regime of impinging jet atomization. A more suitable dynamic range was used for PDA measurements compared to the literature, resulting in more accurate experimental measurements for drop diameters and velocities. There is some disagreement in the literature regarding the ability of linear stability analysis to accurately predict drop diameters in the impact wave regime. This work seeks to provide some clarity. It was discovered that the assumed uniform jet velocity profile was a contributing factor for deviation between diameter predictions based on models in the literature and experimental measurements. Analytical expressions that depend on parameters based on the assumed jet velocity profile are presented in this work. Predictions based on the parabolic and 1/7th power law turbulent profiles were considered and show better agreement with the experimental measurements compared to predictions based on the previous models. Experimental mean drop velocity measurements were compared with predictions from a force balance analysis, and it was observed that the assumed jet velocity profile also influences the predicted velocities, with the turbulent profile agreeing best with the experimental mean velocity. It is concluded that the assumed jet velocity profile has a predominant effect on drop diameter and velocity predictions.

Similar content being viewed by others

Abbreviations

- b*:

-

Dimensionless distance from center of jet to separation point (−)

- d D :

-

Predicted drop diameter (μm)

- d j :

-

Jet diameter (mm)

- d 0 :

-

Orifice diameter (mm)

- D 10 :

-

Arithmetic mean drop diameter (μm)

- D 32 :

-

Sauter mean drop diameter (μm)

- f 0 :

-

Number pdf (μm −1)

- f 2 :

-

Area pdf (μm−1)

- f 3 :

-

Volume pdf (μm−1)

- Fr j :

-

Jet Froude number (−)

- K*:

-

Dimensionless sheet thickness parameter (−)

- MMD:

-

Mass median diameter (μm)

- q*:

-

Dimensionless radial distance from the separation point (−)

- q j*:

-

Dimensionless location of the jet interface (−)

- R j :

-

Jet radius (mm)

- Re D :

-

Drop Reynolds number (−)

- Re j :

-

Jet Reynolds number (−)

- s :

-

Ratio of ambient gas density to liquid density (−)

- U j :

-

Jet velocity (m s−1)

- U d :

-

Drop velocity (m s−1)

- U z−mean :

-

Experimentally measured mean drop velocity (m s−1)

- We d :

-

Drop Weber number (−)

- We j :

-

Jet Weber number (−)

- L/d 0 :

-

Internal length-to-orifice diameter ratio (−)

- x/d 0 :

-

Free jet length-to-orifice diameter ratio (−)

- α :

-

Ratio of sheet velocity to jet velocity (−)

- γ :

-

Liquid/gas surface tension (N/m)

- θ :

-

Half-impingement angle (°)

- μ l :

-

Liquid viscosity (Pa s)

- ρ g :

-

Ambient gas density (kg m−3)

- ρ l :

-

Liquid density (kg m−3)

- ϕ :

-

Sheet azimuthal angle (°)

References

Albrecht HE, Borys M, Damaschke N, Tropea C (2003) Laser doppler and phase doppler measurement techniques. Springer, Berlin

Anderson WE, Ryan HM, Pal S, Santoro RJ (1992) Fundamental studies of impinging liquid jets. AIAA. Paper No. 92-0458

Anderson WE, Ryan HM, Santoro RJ (1995) Impinging jet injector atomization. In: Yang V, Anderson WE (eds) Liquid rocket engine combustion instability. Progress in Astronautics and Aeronautics, Washington, DC, pp 215–246

Anderson WE, Ryan HM, Santoro RJ (2006) Impact wave-based model of impinging jet atomization. Atomization Sprays 16:791–805

Bremond N, Villermaux E (2006) Atomization by jet impact. J Fluid Mech 549:273–306

Choo YJ, Kang BS (2007) The effect of jet velocity profile on the characteristics of thickness and velocity of the liquid sheet formed by two impinging jets. Phys Fluids A 19:11

Dombrowski ND, Hooper PC (1963) A study of the sprays formed by impinging jets in laminar and turbulent flow. J Fluid Mech 18:392–400

Dombrowski ND, Johns WR (1963) The aerodynamic instability and disintegration of viscous liquid sheets. Chem Eng Sci 18:203–214

Gill GS, Nurick WH (1976) Liquid rocket engine injectors. NASA SP-8089

Guildenbecher DR, López-Rivera C, Sojka PE (2009) Secondary atomization. Exp Fluids 46:371–402

Hasson D, Peck RE (1964) Thickness distribution in a sheet formed by impinging jets. AIChE J 10:752–754

Heidmann MF, Priem RJ, Humphrey JC (1957) A study of sprays formed by two impinging jets. NACA TN D-301

Heister SD (2011) Pintle Injectors. In: Ashgriz N (ed) Handbook of atomization and sprays. Springer, New York, pp 647–655

Humble RW, Henry GN, Larson WJ (1995) Space propulsion analysis and design. McGraw-Hill, New York

Ibrahim EA (2009) Comment on “Atomization characteristics of impinging liquid jets”. J Propuls Power 25:1361–1362

Ibrahim EA, Przekwas AJ (1991) Impinging jets atomization. Phys Fluids A 3:2981–2987

Kang BS, Poulikakos D (1996) Holography experiments in a dense high-speed impinging jet spray. J Propuls Power 12:341–348

Kline SJ, McClintock FA (1953) Describing uncertainties in single-sample experiments. Mech Eng 75:3–8

Lefebvre AH (1989) Atomization and sprays. Hemisphere, New York

Mallory JA, Sojka PE (2014) On the primary atomization of non-Newtonian impinging jets: volume I experimental investigation. Atomization Sprays 24:431–465

Rodrigues NS (2014) Impinging jet spray formation using non-Newtonian liquids. MS thesis, Purdue University

Rodrigues NS, Sojka PE (2014) A parametric investigation of gelled propellant spray characteristics utilizing impinging jet geometry. AIAA. Paper No. 2014-1184

Ryan HM (1995) Fundamental study of impinging jet atomization. PhD dissertation, The Pennsylvania State University

Ryan HM, Anderson WE, Pal S, Santoro RJ (1995) Atomization characteristics of impinging liquid jets. J Propuls Power 11:135–145

Senecal PK, Schmidt DP, Nouar I, Rutland CJ, Reitz RD, Corradini ML (1999) Modeling high-speed viscous liquid sheet atomization. Intl J Multiph Flow 25:1073–1097

Sirignano WA, Mehring C (2000) Review of theory of distortion and disintegration of liquid streams. Prog Energy Comb Sci 26:609–655

Squire HB (1953) Investigation of the instability of a moving liquid film. Brit J Applied Phys 4:167–169

Vingert L, Gicquel P, Lourme D, Menoret L (1995) Coaxial injector atomization. In: Yang V, Anderson WE (eds) Liquid rocket engine combustion instability. Progress in Astronautics and Aeronautics, Washington, DC, pp 145–190

Von Kampen J, Madlener K, Ciezki HK (2006) Characteristic flow and spray properties of gelled fuels with regard to the impinging jet injector. AIAA. Paper No. 2006-4573

Weber C (1931) Disintegration of liquid jets. Zeitschrift für Angewandte Mathematik und Mechanik 11:136–159

Acknowledgments

The research presented in this paper was made possible with the financial support of the U.S. Army Research Office under the Multi-University Research Initiative Grant Number W911NF-08-1-0171. N. S. Rodrigues thanks Prof. Jennifer Mallory for helpful feedback, Dr. Ariel Muliadi for assistance with PDA configuration, and Prof. William Anderson for fruitful discussions.

Author information

Authors and Affiliations

Corresponding authors

Appendix

Appendix

For the assumption of a parallel-sided sheet, instead of an attenuating sheet, the sheet thickness is constant. Therefore, as outlined in Senecal et al. (1999), the following expression can be used as a condition for breakup:

In keeping with the long-wave approximation (kh/2 ≪ 1), an analytical expression can also be derived for drop diameter. This expression depends on the jet Weber number We j , ratio of sheet velocity to mean jet velocity α, dimensionless sheet thickness parameter K*, and ratio of ambient gas density to liquid density s:

Figure 11 presents a comparison of the experimental MMD to the predicted diameters given by the two-step breakup mechanism with the parallel-sided sheet for parabolic, turbulent, and uniform jet velocity profiles. The parallel-sided sheet assumption is useful for predictions for viscous Newtonian and non-Newtonian liquids, where the inviscid assumption cannot be justified.

Rights and permissions

About this article

Cite this article

Rodrigues, N.S., Kulkarni, V., Gao, J. et al. An experimental and theoretical investigation of spray characteristics of impinging jets in impact wave regime. Exp Fluids 56, 50 (2015). https://doi.org/10.1007/s00348-015-1917-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00348-015-1917-7