Abstract

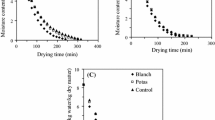

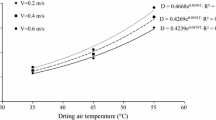

In this study, the effect of drying temperature on drying behaviour and mass transfer parameters of lemon slices was investigated. The drying experiments were conducted in a laboratory air ventilated oven dryer at temperatures of 50, 60 and 75 °C. It was observed that the drying temperature affected the drying time and drying rate significantly. Drying rate curves revealed that the process at the temperature levels taken place in the falling rate period entirely. The usefulness of eight thin layer models to simulate the drying kinetics was evaluated and the Midilli and Kucuk model showed the best fit to experimental drying curves. The effective moisture diffusivity was determined on the basis of Fick’s second law and obtained to be 1.62 × 10−11, 3.25 × 10−11 and 8.11 × 10−11 m2 s−1 for the temperatures of 50, 60 and 75 °C, respectively. The activation energy and Arrhenius constant were calculated to be 60.08 kJ mol−1 and 0.08511 m2 s−1, respectively. The average value of convective mass transfer coefficient for the drying temperatures of 50, 60 and 75 °C was calculated to be 5.71 × 10−7, 1.62 × 10−6 and 2.53 × 10−6 m s−1, respectively.

Similar content being viewed by others

Abbreviations

- Deff :

-

Effective moisture diffusivity (m2 s−1)

- Do :

-

Arrhenius constant (m2 s−1)

- Ea :

-

Activation energy (kJ mol−1)

- H:

-

Half thickness of samples (m)

- M:

-

Moisture content (gwater/gdry matter)

- Me :

-

Equilibrium moisture content (gwater/gdry matter)

- Mo :

-

Initial moisture content (gwater/gdry matter)

- MR:

-

Moisture ratio (–)

- MRexp,i :

-

The ith experimental moisture ratio (–)

- MRpre,i :

-

The ith predicted moisture ratio (–)

- \(\overline{MR}\) :

-

Average experimental moisture ratio (–)

- MRE:

-

Mean relative error (%)

- N:

-

Number of observation (–)

- R:

-

Universal gas constant (kJ mol−1 k−1)

- R2 :

-

Means of coefficient of determination (–)

- RMSE:

-

Root mean square error (%)

- t:

-

Drying time (s)

- T:

-

Drying temperature (°C)

- Tabs :

-

Absolute temperature (°k)

- Z:

-

Number of constants (–)

- χ 2 :

-

Chi square (–)

References

Ladaniya MS (2008) Citrus fruit: biology, technology and evaluation. Elsevier, New York

Diaz GR, Martinez-Monzo J, Fito P, Chiralt A (2003) Modelling of dehydration-rehydration of orange slices in combined microwave/air drying. Innov Food Sci Emerg Technol 4:203–209

Torki-Harchegani M, Ghanbarian D, Sadeghi M (2014) Estimation of whole lemon mass transfer parameters during hot air drying using different modelling methods. Heat Mass Transf. doi:10.1007/s00231-014-1483-1

Sadeghi M, Mirzabeigi Kesbi O, Mireei SA (2013) Mass transfer characteristics during convective, microwave and combined microwave-convective drying of lemon slices. J Sci Food Agric 93:471–478

Doymaz I (2011) Thin-layer drying characteristics of sweet potato slices and mathematical modelling. Heat Mass Transf 47:277–285

Simal S, Femenia A, Garau MC, Rosselló C (2005) Use of the exponential, Page’s and diffusional model to simulate the drying kinetics of kiwi fruit. J Food Eng 66:323–328

Demiray E, Tulek Y (2012) Thin-layer drying of tomato (Lycopersicum esculentum Mill. cv. Rio Grande) slices in a convective hot air dryer. Heat Mass Transf 48:841–847

Midilli A (2001) Determination of pistachio drying behavior and conditions in a solar drying system. Int J Energy Res 25:715–725

Midilli A, Kucuk H (2003) Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Convers Manag 44:1111–1122

Sarsavadia PN, Sawhney RL, Pangavhane DR, Singh SP (1999) Drying behaviour of brined onion slices. J Food Eng 40:219–226

Wang CY, Singh RP (1978) A thin layer drying equation for rough rice. In: ASAE paper 78-3001

Hii CL, Law CL, Cloke M (2009) Modeling using a new thin layer drying model and product quality of cocoa. J Food Eng 90:191–198

Ayensu A (1997) Dehydration of food crops using a solar dryer with convective heat flow. Sol Energy 59:121–126

Karathanos VT, Belessiotis VG (1999) Application of a thin layer equation to drying data of fresh and semi-dried fruits. J Agric Eng Res 74:355–361

Chhinman MS (1984) Evaluation of selected mathematical models for describing thin layer drying of in-shell pecans. Trans ASABE 27:610–615

Yaldiz O, Ertekin C, Uzun HB (2001) Mathematical modelling of thin layer solar drying of sultana grapes. Energy 26:457–465

Midilli A, Kucuk H, Yapar Z (2002) A new model for single layer drying. Dry Technol 20:1503–1513

Henderson SM (1974) Progress in developing the thin-layer drying equation. Trans ASABE 17:1167–1168

Kassem AS (1998) Comparative studies on thin layer drying models for wheat, vol 6. Paper presented in 13th international congress on agricultural engineering, Morocco

Duc LA, Han JW, Keum DH (2011) Thin layer drying characteristics of rapeseed (Brassica napus L.). J Stored Prod Res 47:32–38

Izli N, Yildiz G, Ünal H, Isik E, Uylaser V (2014) Effect of different drying methods on drying characteristics, colour, total phenolic content and antioxidant capacity of Goldenberrgy (Physalis peruviana L.). Int J Food Sci Technol 49:9–17

Singh NJ, Pandey RK (2012) Convective air drying characteristics of sweet potato cube (Ipomoea batatas L.). Food Biprod Process 90:317–322

Doymaz I, Ismail O (2011) Drying characteristics of sweet cherry. Food Bioprod Process 89:31–38

Tulek Y (2011) Drying kinetic of oyster mushroom (Pleurotus ostreatus) in a convective hot air dryer. J Agric Sci Technol 13:655–664

Balbay A, Sahin O, Ulker H (2013) Modeling of convective drying kinetics of pistachio kernels in a fixed bed drying system. Therm Sci 17:839–846

Dak M, Pareek NK (2014) Effective moisture diffusivity of pomegranate arils undergoing microwave-vacuum drying. J Food Eng 122:117–121

Chen HH, Hernandez CE, Huang TC (2005) A study of the drying effect on lemon slices using a closed-type solar dryer. Sol Energy 78:97–103

Association of Official Analytical Chemists Official (1997) Methods of analysis, 14th edn. AOAC, Washington

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Dincer I, Dost S (1995) An analytical model for moisture diffusion in solid objects during drying. Dry Technol 13:425–435

Kaya A, Aydin O, Demirtas C (2007) Concentration boundary conditions in the theoretical analysis of convective drying process. J Food Process Eng 30:546–577

Holman JP (2001) Experimental methods for engineers, 7th edn. McGraw-Hill, New York

Amiri Chayjan R, Tabatabaei Bahrabad SM, Rahimi Sardari F (2013) Modeling infrared-convective drying of pistachio nuts under fixed and fluidized bed conditions. Food Process Preserv. doi:10.1111/jfpp.12083

Zheng DJ, Cheng YQ, Liu HJ, Li LT (2011) Investigation of EHD-enhanced water evaporation and a novel empirical model. Int J Food Eng. doi:10.2202/1556-3758.1796

Olanipekun BF, Tunde-Akintunde TY, Oyelade OJ, Adebisi MG, Adenaya TA (2014) Mathematical modelling of thin-layer pineapple drying. J Food Process Preserv. doi:10.1111/jfpp.12362

Demiray E, Tulek Y (2013) Drying characteristics of garlic (Allium sativum L) slices in a convective hot air dryer. Heat Mass Transf. doi:10.1007/s00231-013-1286-9

Sacilik K, Elicin AK (2006) The thin layer drying characteristics of organic apple slices. J Food Eng 73:281–289

Tunde-Akintunde TY (2012) Effect of pretreatments on drying characteristics and energy requirements of plantain (Musa aab). J Food Process Preserv. doi:10.1111/jfpp.12156

Corrêa PC, Oliveira GHH, Botelho FM, Goneli ALD, Carvalho FM (2010) Mathematical modeling and determination of thermodynamic properties of coffee (Coffea arabica L.) during the drying process. Revista Ceres 57:595–601

Aghbashlo M, Kianmehr MH, Samimi-Akhijahani H (2008) Influence of drying conditions on the effective moisture diffusivity, energy of activation and energy consumption during the thin-layer drying of berberis fruit (Berberidaceae). Energy Convers Manag 49:2865–2871

Minaei S, Motevali A, Ahmadi E, Azizi MH (2012) Mathematical models of drying pomegranate arils in vacuum and microwave dryers. J Agric Sci Technol 14:311–325

Azzouz S, Guizani A, Jomaa W, Belghith A (2002) Moisture diffusivity and drying kinetic equation of convective drying of grapes. J Food Eng 55:323–330

Kaymak-Ertekin F (2002) Drying and rehydration kinetics of green and red pepper. J Food Sci 67:168–175

Kaya A, Aydin O, Dincer I (2010) Comparison of experimental data with results of some drying models for regularly shaped products. Heat Mass Transf 46:555–562

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Torki-Harchegani, M., Ghasemi-Varnamkhasti, M., Ghanbarian, D. et al. Dehydration characteristics and mathematical modelling of lemon slices drying undergoing oven treatment. Heat Mass Transfer 52, 281–289 (2016). https://doi.org/10.1007/s00231-015-1546-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-015-1546-y