Abstract

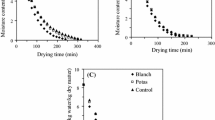

The effects of different drying temperatures on the drying kinetics of tomato slices were investigated using a cabinet-type dryer. The experimental drying data were fitted best to the to the Page and Modified Page models apart from other theoretical models to predict the drying kinetics. The effective moisture diffusivities varied from 1.015 × 10−9 to 2.650 × 10−9 m2 s−1over the temperature range studied, and activation energy was 22.981 kJ mol−1.

Similar content being viewed by others

Abbreviations

- a, b, c, n :

-

Constants of models

- k, k 0, k 1 :

-

Rate constants in models, h−1

- MR:

-

Moisture ratio

- D eff :

-

Effective diffusivity (m2 s−1)

- D 0 :

-

Pre-exponential factor of the Arrhenius equation (m2 s−1)

- E a :

-

Activation energy (kJ mol−1)

- L :

-

Half-thickness of the slab in samples, m

- M t :

-

Moisture content, g water/g dry matter

- M e :

-

Equilibrium moisture content, g water/g dry matter

- M 0 :

-

Initial moisture content, g water/g dry matter

- N :

-

Number of observations

- n :

-

Positive integer, constant

- R 2 :

-

Correlation coefficient

- RMSE:

-

Root mean square error

- T :

-

Temperature, °C

- t :

-

Drying time, min

- χ2 :

-

Reduced chi-square

- z :

-

Number of constants in models

References

Durance TD, Wang JH (2002) Energy consumption, density and rehydration rate of vacuum microwave and hot-air convection dehydrated tomatoes. J Food Sci 67:2212–2216

Andritsos N, Dalampakis P, Kolios N (2003) Use of geothermal energy for tomato drying. GHC Bull 24:9–13 (March)

Doymaz I (2007) Air drying characteristics of tomatoes. J Food Eng 78:1291–1297

Ertekin C, Yaldiz O (2004) Drying of eggplant and selection of a suitable thin layer drying model. J Food Eng 63:349–359

Giovanelli G, Zanoni B, Lavelli V, Nani R (2002) Water sorption, drying and antioxidant properties or dried tomato products. J Food Eng 52:135–141

Toor RK, Savage GP (2006) Effect of semi-drying on the antioxidant components of tomatoes. Food Chem 94:90–97

Veillet S, Busch J, Savage G (2009) Acceptability and antioxidant properties of a semi-dried and smoked tomato product. J Food Agric Environ 7(2):70–75

Koca N, Burdurlu HS, Karadeniz F (2007) Kinetics of colour changes in dehydrated carrots. J Food Eng 78:449–455

Sahin AZ, Dincer I (2005) Prediction of drying times for irregular shaped multi-dimensional objects. J Food Eng 71(1):119–126

Ozdemir M, Devres YO (1999) The thin layer drying characteristics of hazelnuts during roasting. J Food Eng 42:225–233

McMinn WAM (2006) Thin-layer modeling of the convective, microwave, microwave-convective and microwave-vacuum drying of lactose powder. J Food Eng 72:113–123

Kaleemullah S, Kailappan R (2005) Drying kinetics of red chilies in rotary dryer. Biosyst Eng 92:15–23

Akpinar EK, Bicer Y (2005) Modeling of the drying of eggplants in thin-layers. Int J Food Sci Technol 40:273–281

Yaldiz O, Ertekin C (2001) Thin layer solar drying of some different vegetables. Drying Technol 19:583–596

Doymaz I (2005) Drying characteristics and kinetics of okra. J Food Eng 69:275–279

Maskan M, Gogus F (1998) Sorption isotherms and drying characteristics of mulberry (Morus alba). J Food Eng 37:437–449

Sacilik K, Keskin R, Elicin KA (2006) Mathematical modeling of solar tunnel drying of thin layer organic tomato. J Food Eng 73:231–238

AOAC (1990) Official method of analysis. Association of Official Analytical Chemists (No. 934.06), Arlington

Tabatabaee R, Jayas DS, White NDG (2004) Thin-layer drying and rewetting characteristics of buckwheat. Can Biosyst Eng 46(3):19–24

Sarsavadia PN, Sawhney RL, Pangavhane DR, Singh SP (1999) Drying behavior of brined onion slices. J Food Eng 46:219–226

Doymaz I, Pala M (2002) The effects of dipping pretreatments on air-drying rates of the seedless grapes. J Food Eng 52:413–417

Simal S, Femenia A, Garau MC, Rossello C (2005) Use of exponential, page’s and diffusional models to simulate the drying kinetics of kiwi fruit. J Food Eng 66:323–328

Doymaz I (2007) The kinetics of forced convective air-drying of pumpkin slices. J Food Eng 79:243–248

Bruce DM (1985) Exposed-layer barley drying, three models fitted to new data up to 150°C. J Agric Eng Res 32:337–347

Yaldiz O, Ertekin C, Uzun HI (2001) Mathematical modeling of thin layer solar drying of sultana grapes. Energy 26:457–465

Togrul IT, Pehlivan D (2004) Modeling of thin layer drying kinetics of some fruits under open-air sun drying process. J Food Eng 65:413–425

Sharma GP, Verma RC, Pathare PB (2005) Thin layer infrared radiation drying of onion slices. J Food Eng 67:361–366

Saravacos GD, Maroulis ZB (2001) Transport properties of foods. Marcel Dekker Inc., New York

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, London

Lomauro CJ, Bakshi AS, Labuza TP (1985) Moisture transfer properties of dry and semimoist foods. J Food Sci 50:397–400

Akpinar EK (2006) Mathematical modeling of thin layer drying process under open sun of some aromatic plants. J Food Eng 77:864–870

Madamba PS, Driscoll RH, Buckle KA (1996) The thin layer drying characteristics of garlic slices. J Food Eng 29:75–97

San JN, Lozano M, Garcia PP, Mulet A (2003) Dehydration kinetics of red pepper (Capsicum annuum L var Jaranda). J Sci Food Agric 83:697–701

Fang S, Wang Z, Hu X (2009) Hot air drying of whole fruit Chinese jujube (Zizyphus jujube Miller) thin layer mathematical modeling. Int J Food Sci Technol 44:1818–1824

Akpinar EK, Bicer Y, Yildiz C (2003) Thin layer drying of red pepper. J Food Eng 59:99–104

Sogi DS, Shivhare US, Bawa AS, Garg SK (2003) Water sorption isotherms and drying characteristics of tomato seeds. Biosyst Eng 84(3):297–301

Kaur D, Wani AA, Sogi DS, Shivhare US (2006) Sorption isotherms and drying characteristics of tomato peel isolated from tomato pomace. Drying Technol 24:1515–1520

Chawla C, Kaur D, Oberoi DPS, Sogi DS (2008) Drying characteristics, sorption isotherms, and lycopene retention of tomato pulp. Drying Technol 26:1257–1264

Acknowledgments

The authors would like to thank the Pamukkale University Scientific Researches Unit (Project No: 2008MHF004) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Demiray, E., Tulek, Y. Thin-layer drying of tomato (Lycopersicum esculentum Mill. cv. Rio Grande) slices in a convective hot air dryer. Heat Mass Transfer 48, 841–847 (2012). https://doi.org/10.1007/s00231-011-0942-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-011-0942-1