Abstract

A high accuracy, counter flow double pipe heat exchanger system is designed for the measurement of convective heat transfer coefficients with different nanofluids. Both positive and negative enhancement of convective heat transfer of alumina nanofluids are found in the experiments. A modified equation was proposed to explain above phenomena through the physic properties of nanofluids such as thermal conductivity, special heat capacity and viscosity.

Similar content being viewed by others

Abbreviations

- a :

-

Thermal diffusivity (m2/s)

- A :

-

Heat exchanging area (m2)

- C peff :

-

Effective heat capacity (J/K)

- \(C_{{pH_{2} O}}\) :

-

Heat capacity of water (J/K)

- \(C_{{pAl_{2} O_{3} }}\) :

-

Heat capacity of Al2O3 particle (J/K)

- D :

-

Tube inner diameter (m)

- d f :

-

Fractal dimension of the aggregates (m)

- dTln :

-

Log mean temperature difference (K)

- dt i :

-

Inlet temperature difference (K)

- dt o :

-

Outlet temperature difference (K)

- f :

-

Friction factor

- h :

-

Convective heat transfer coefficient (W/K m2)

- k e :

-

Effective thermal conductivity (W/K m)

- k m :

-

Thermal conductivity of the base liquid (W/K m)

- k p :

-

Solids phase thermal conductivity (W/K m)

- k a :

-

Aggregate thermal conductivity (W/K m)

- Nu :

-

Nusselt number

- Pr :

-

Prandtl number

- Q :

-

Heat flux (W/m2)

- Re :

-

Reynolds number

- r p :

-

Particle radius (m)

- r a :

-

Aggregate gyration radius (m)

- T :

-

Temperature (K)

- t pi :

-

Inlet primary fluid temperature (K)

- t si :

-

Inlet secondary fluid temperature (K)

- t po :

-

Outlet primary fluid temperature (K)

- t so :

-

Outlet secondary fluid temperature (K)

- V :

-

Flow rate (l/min)

- v :

-

Velocity of fluid (m/s)

- v p :

-

Volume fraction of the particle

- w :

-

Weight fraction of the particle

- p :

-

Nanofluid density (kg/m3)

- ρ f :

-

Base fluid density (kg/m3)

- μ :

-

Nanofluids viscosity (Pa s)

- μ f :

-

Base fluid viscosity (Pa s)

- μ w :

-

Viscosity at tube wall temperature (Pa s)

References

Choi SUS (1995) Enhancing thermal conductivity of fluids with nanoparticles. In: The Proceedings of the 1995 ASME International Mechanical Engineering Congress and Exposition, San Francisco, USA, ASME, FED 231/MD 66, pp 99–105

Das SK, Putra N, Thiesen P, Roetzel W (2003) Temperature dependence of thermal conductivity enhancement for nanofluids. ASME J Heat Transf 125:567–574

Eastman JA, Choi SUS, Li S, Yu W, Thompson LJ (2001) Anomalously increased effective thermal conductivity of ethylene glycol-based nanofluids containing copper nanoparticles. Appl Phys Lett 78:718–720

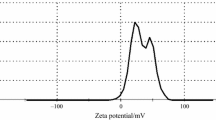

Lee D, Kim JW, Kim BG (2006) A new parameter to control heat transport in nanofluids: surface charge state of the particle in suspension. J Phys Chem B 110:4323–4328

Murshed SMS, Leong KC, Yang C (2005) Enhanced thermal conductivity of TiO2–water based nanofluids. Int J Therm Sci 44:367–373

Xie H, Wang J, Xi T, Liu Y (2002) Thermal conductivity of suspensions containing nanosized SiC particles. Int J Thermophys 23:571–580

Pak BC, Cho YI (1998) Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf 11:151–170

Xuan Y, Li Q (2002) Investigation convective heat transfer and flow features of nanofluids. J Heat Transf 125:151–155

Heris SZ, Etemad SGh, Esfahany MN (2006) Experimental investigation of oxide nanofluids laminar flow convective heat transfer. Int Commun Heat Mass Transf 33:529–533

Heris SZ, Esfahany MN, Etemad SGh (2006) Investigation of CuO/water nanofluid laminar convective heat transfer through a circular tube. J Enhanc Heat Transf 13:1–11

Heris SZ, Esfahany MN, Etemad SGh (2007) Experimental investigation of convective heat transfer of Al2O3/water nanofluid in circular tube. Int J Heat Fluid Flow 28:203–210

Wen D, Ding Y (2004) Experimental investigation into convective heat transfer of nanofluids at the entrance region under laminar flow conditions. Int J Heat Mass Transf 47:5181–5188

Anoop KB, Sundararajan T, Das SK (2009) Effect of particle size on the convective heat transfer in nanofluid in the developing region. Int J Heat Mass Transf 52:2189–2195

Makinde OD (2013) Effects of viscous dissipation and Newtonian heating on boundary layer flow of nanofluids over a flat plate. Int J Numer Methods Heat Fluid flow 23(8):1291–1303

Fotukian SM, Nasr Esfahany M (2010) Experimental investigation of turbulent convective heat transfer of dilute γ-Al2O3/water nanofluid inside a circular tube. Int J Heat Fluid Flow 31:606–612

Ni R, Zhou S, Xia K (2011) An experimental investigation of turbulent thermal convection in water-base alumina nanofluid. Phys Fluids 23:022005–022017

Bejan A, Sciubba E (1992) The optimal spacing for parallel plates cooled by forced convection. Int J Heat Mass Transf 35:3259–3264

Hajmohammadi MR, Salimpour MR, Saber M, Campo A (2013) Detailed analysis for the cooling performance enhancement of a heat source under a thick plate. Energy Convers Manag 76:691–700

Hajmohammadi MR, Moulod M, Shariztzadeh OJ, Nourazar SS New methods to cope with temperature elevations in heated segments of flat plates cooled by boundary layer flow. Therm Sci doi:10.2298/TSCI130128159H

Hajmohammadi MR, Campo A, Nourazar SS, Ostad AM (2013) Improvement of forced convection cooling due to the attachment of heat sources to a conducting thick plate. J Heat Transf Trans ASME 135:124504

Hajmohammadi MR, Eskandari H, Saffar-Avval M, Campo A (2013) A new configuration of bend tubes for compound optimization of heat and fluid flow. Energy 62:418–424

Maxwell JC (1873) Treatise on electricity and magnetism. Clarendon Press, Oxford

Prasher R, Phelan PE, Bhattacharya P (2006) Effect of aggregation kinetics on the thermal conductivity of nanoscale colloidal solutions (nanofluid). Nano Lett 6:1529–1534

Li CH, Peterson GP (2006) Experimental investigation of temperature and volume fraction variations on the effective thermal conductivity of nanoparticle suspensions (nanofluids). J Appl Phys 99:084314–084322

Masuda H, Ebata A, Teramae K, Hishiuma N (1993) Alteration of thermal conductivity and viscosity of liquid by dispersing ultra-fine particles (dispersion of γ-Al2O3, SiO2, and TiO2 ultra-fine particles). Netsu Bussei 7:227–233

Duan F, Kwek D, Crivoi A (2011) Viscosity affected by nanoparticle aggregation in Al2O3–water nanofluids. Nanoscale Res Lett 6:248–253

Sundar LS, Ramanathan S, Sharma KV, Babu PS (2007) Temperature dependent flow characteristics of Al2O3 nanofluid. Int J Nanotechnol Appl 2:35–44

Seider EN, Tate GE (1936) Heat transfer and pressure drop of liquid in tubes. Ind Eng Chem 28(12):1429–1435

Zhukauskas A (1972) Heat transfer from tubes in cross flow. Adv Heat Transf 8:93–160

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, J., Ding, Y. & Ma, C. Aqueous Al2O3 nanofluids: the important factors impacting convective heat transfer. Heat Mass Transfer 50, 1639–1648 (2014). https://doi.org/10.1007/s00231-014-1374-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-014-1374-5