Abstract

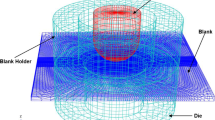

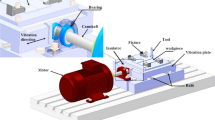

Cold-rolled low carbon steel sheets of thicknesses ranging from 0.8 to 2 mm were sheets welded together to form a single part before the formability tests. In this study, the formability of the tailor-welded blanks (TWBs) was evaluated in terms of three measures which are limited dome height (LDH), forming limit diagram (FLD), and minimum major strain. In addition to the mechanical properties, the welded specimens were analyzed experimentally under the effect of thickness ratios. The influence of welding orientation and its relation with the rolling direction on formability and mechanical properties were also studied. The mechanical properties of the welded specimens were investigated by tensile testing and micro-hardness measurements. The metallographic studies were investigated using optical microscope and scanning electron microscope (SEM). The experimental findings in this study showed that the higher the thickness ratio of the TWBs, the lower the forming limits curve level and the lower formability. The minimum major strain was clearly inversely proportional to the thickness ratio of the TWBs. On the other hand, the results of uniaxial tests clearly illustrated that there was no significant difference between the tensile strengths of the TWBs and base metal. The micro-hardness measurements indicated that the hardness in the weld bead increased by about 55 % of the base metal.

Similar content being viewed by others

References

Zhao KM, Chun BK, Lee JK (2001) Finite element analysis of tailor-welded blanks. Finite Elem Anal Des 37:117–130

Dreyer CE, Chiu WV, Wagoner RH (2009) Formability of a more randomly textured magnesium alloy sheet application of an improved warm sheet formability test. J Mater Process Technol 210:37–47

Dabhi HO, Thanki SJ, Patel VK (2014) Experimental and numerical investigation of tailor welded blanks [TWBs]. Int J Adv Mech Eng 4(6):589–599

Song Xue, Jie Zhou and Ying-Qiang He (2011) Tensile testing on formability of different gauge tailor-welded blanks. Open Mater Sci J 5:89–92

Sato YS, Sugiura Y, Shoji Y, Park SHC, Kokawa H (2004) Post-weld formability of friction stir welded Al alloy 5052”. Mater Sci Eng A369:138–143

Gaied S, Pinard F, Schmit F, Roelandt JM (2009) Experimental and numerical assessment of tailor-welded blanks formability. J Mater Process Technol 209:387–395

Kusuda H, Takasago T, Natsumi F (1997) Formability of tailored blanks. J Mater Process Technol 71:134–140

Goud, R. Raman, K. Eswar Prasad, and Swades Kumar Singh (2014) Formability limit diagrams of extra-deep-drawing steel at elevated temperatures. Procedia Mater Sci 6:123–128

Sharma RS, Molian P (2009) Yb:YAG laser welding of TRIP780 steel with dual phase and mild steels for use in tailor welded blanks. Mater Des 30(10):4146–4155

Chan SM, Chan LC, Lee TC (2003) Tailor-welded blanks of different thickness ratios effects on forming limit diagrams. J Mater Process Technol 132:95–101

Sheng ZQ (2008) Formability of tailor-welded strips and progressive forming test. J Mater Process Technol

Mamusi H, Masoumi A, Mahdavinezhad R (2012) Numerical simulation for the formability prediction of the laser welded blanks (TWB). World Acad Sci Eng Technol 6:07–20

Khan, Arman, V.v.n. Satya Suresh, and Srinivasa Prakash Regalla (2014) Effect of thickness ratio on weld line displacement in deep drawing of aluminium steel tailor welded blanks. Procedia Mater Sci 6:401–408

Standard Test Methods for Tension Testing of Metallic Materials [Metric], ASTM Standard E 8M-01

Standard Test Method for Determining Forming Limit Curves, ASTM Standard E 2218 – 02, Vol 01.03, 2002

Leitão C, Emílio B, Chaparro BM, Rodrigues DM (2009) Formability of similar and dissimilar friction stir welded AA 5182-H111 and AA 6016-T4 tailored blanks. Mater Des 30:3235–3242

Chen LX, Bhandhubanyong P, Vajragupta W, Somsiri C (1997) Plastic properties of low-carbon steel sheets. J Mater Process Technol 63(1-3):95–99

Pandaa SK, Kumara DR, Kumarb H, Nathb AK (2007) Characterization of tensile properties of tailor welded IF steel sheets and their formability in stretch forming. J Mater Process Technol 183:321–322

Chan LC, Chan SM, Cheng CH, Lee TC (2005) Formability and weld zone analysis of tailor-welded blanks for various thickness ratios. J Eng Mater Technol 127:179

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Elshalakany, A.B., Ali, S., Osman, T.A. et al. An experimental investigation of the formability of low carbon steel tailor-welded blanks of different thickness ratios. Int J Adv Manuf Technol 88, 1459–1473 (2017). https://doi.org/10.1007/s00170-016-8874-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8874-z