Abstract

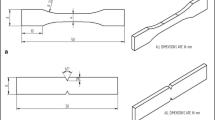

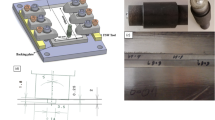

The manufacturing industries are keen on understanding the effect of weld line orientation on the formability characteristics of tailor-welded blanks (TWBs) with sheets for the design and manufacture of structures with lightweight. The AISI 316L sheets of 2 mm and 1.6 mm were welded together by cold metal transfer (CMT) process using a welding current of 95 Amperes and a welding speed of 350 mm/min to fabricate TWBs. Two different TWBs were made with the welding line parallel to the rolling direction RD (WL||RD) and the weld line perpendicular to the RD (WL⊥RD). The quality of the TWBs was evaluated by microstructural examination, mechanical integrity by tensile, hardness and Erichsen cupping test with laboratory-scale specimens. The engineering stress–strain plot and formability characteristics of the TWBs were considerably influenced by the weld line orientation with respect to the RD. It was noticed that the formability of TWBs decreased slightly compared to the base metal (BM) and fracture appeared in the thinner region (1.6 mm side), away from the weld line. Finite element (FE) prediction of Erichsen cup height was performed with ABAQUS software considering the weld metal properties. FE analysis using Johnson–Cook damage criterion predicted a cupping height that showed good coherence with experimental measurements for BM and TWBs with an error percentage less than 5. The stress distribution was non-uniform in the deformed TWBs with more stretching, and the magnitude of deformation was higher in the thinner region.

Similar content being viewed by others

References

Molak RM, Paradowski K, Brynk T, Ciupinski L, Pakiela Z, Kurzydlowski KJ (2009) Measurement of mechanical properties in a 316L stainless steel welded joint. Int J Press Vessels Pip 86(1):43–47

Kianersi D, Mostafaei A, Amadeh AA (2014) Resistance spot welding joints of AISI 316L austenitic stainless steel sheets: phase transformations, mechanical properties and microstructure characterizations. Mater Des 61:251–263

Kannan AR, Shanmugam NS, Sreedhar G (2020) Studies on corrosion behavior of AISI 316L cold metal transfer weldments in physiological solutions. Proc Inst Mech Eng Part E J Process Mech Eng 234(6):644–656

Ozyurek D (2008) An effect of weld current and weld atmosphere on the resistance spot weld-ability of 304L austenitic stainless steel. Mater Des 29:597–603

Trigwel S, Selvaduray G (2005) Effects of welding on the passive oxide film of electro polished 316L stainless steel. J Mater Process Technol 166:30–43

Unnikrisnan R, Idury KSNS, Ismail TP, Bhadauria A, Shekhawat SK, Khatirkar RK, Sapate SG (2014) Effect of heat input on the microstructure, residual stresses and corrosion resistance of 304L austenitic stainless steel weldments. Mater Charact 93:10–23

He X, Wang Y, Lu Y, Zeng K, Gu F, Ball A (2015) Self-piercing riveting of similar and dissimilar titanium sheet materials. Int J Adv Manuf Technol 80(9–12):2105–2115

Kinsey B, Liu Z, Cao J (2000) Novel forming technology for tailor welded blanks. J Mater Process Technol 99(1):145–153

Kahraman N (2007) The influence of welding parameters on the joint strength of resistance spot-welded titanium sheets. Mater Des 28(2):420–427

Zadpoor AA, Sinke J, Benedictus R (2007) Mechanics of tailor welded blanks: an overview. Key Eng Mater 344:373–382

Sheng ZQ (2008) Formability of tailor-welded strips and progressive forming test. J Mater Process Technol 205(1–3):81–88

Lathabai S, Jarvis BL, Barton KJ (2001) Comparison of keyhole and conventional gas tungsten arc welds in commercially pure titanium. Mater Sci Eng A 299(1–2):81–93

Prakash PSL, Biswal SK, Roy GG, Jha MN, Mascarenhas M, Panda SK (2018) Effect of orientation of weld line on formability of electron beam-welded dissimilar thickness titanium sheets. J Mater Eng Perform 27(11):5913–5925

Yigit F, Hashmi MSJ (2012) Effect of laser welding parameters on forming behavior of tailor welded blanks. Adv Mater Res 445:406–411

Guruvu V, Kalimuthu R, Chinnaiyan SN, Marimuthu K (2018) Optimization of formability of tailor-welded blanks. Mater Technol 52(2):151–155

Lorenzin G, Rutili G (2009) The innovative use of low heat input in welding, experiences on ‘cladding’ and brazing using the CMT process. Weld Int 23(8):622–632

Oh KS, Oh KH, Jang JH, Kim DJ, Han KS (2011) Design and analysis of new test method for evaluation of sheet metal formability. J Mater Process Technol 211(4):695–707

Hecker SS (1974) A cup test for assessing stretchability. Metals Eng Quart 14(4):30–36

Narasimhan K, Miles MP, Wagoner RH (1995) A better sheet-formability test”. J Mater Process Technol 50(1–4):385–394

Patel BC, Shah J, Shah H (2012) Review on formability of tailor welded blanks. Int J Theor Appl Res Mech Eng 1(1):89–94

Davies RW, Oliver HE, Smith MT, Grant GJ (1999) Characterizing Al tailor-welded blanks for automotive applications. J Miner Met Mater Soc 51(11):46–50

Hamidinejad SM, Hasanniya MH, Salari N et al (2013) CO2 laser welding of interstitial free galvanized steel sheets used in tailor welded blanks. Int J Adv Manuf Technol 64:195–206

Bandyopadhyay K, Panda SK, Saha P (2014) Prediction of formability of laser-welded dual-phase steel by finite element analysis. Proc Inst Mech Eng Part B J Eng Manuf 228(9):1048–1057

Narooei K, Taheri AK (2009) A study on sheet formability by a stretch-forming process using assumed strain FEM”. J Eng Math 65(4):311–324

Li W, Ma L, Peng P, Jia Q, Wan Z, Zhu Y, Guo W (2018) Microstructural evolution and deformation behavior of fiber laser welded QP980 steel joint. Mater Sci Eng A 717:124–133

Song Y, Hua L (2012) Influence of inhomogeneous constitutive properties of weld materials on formability of tailor welded blanks. Mater Sci Eng A 552:222–229

Habibi M, Hashemi R, Fallah Tafti M, Assempour A (2018) Experimental investigation of mechanical properties, formability and forming limit diagrams for tailor-welded blanks produced by friction stir welding. J Manuf Process 31:310–323

Habibi M, Hashemi R, Ghazanfari A, Naghdabadi R, Assempour A (2016) Forming limit diagrams by including the M–K model in finite element simulation considering the effect of bending. Proc Inst Mech Eng Part L J Mater Des Appl 232:625–636

Moayedi H, Darabi R, Ghabussi A, Habibi M, Foong LK (2020) Weld orientation effects on the formability of tailor welded thin steel sheets. Thin-Walled Struct 149:106669

Placidi F, Fraschetti S. Potential application of stainless steel for vehicle crashworthiness structures. https://www.phase-trans.msm.cam.ac.uk/2005/LINK/142.pdf

International Stainless Steel Forum. https://www.worldstainless.org/Files/issf/non-image-files/PDF/Automotiveapplications.pdf

Ghosh N, Pal PK, Nandi G (2018) Investigation on dissimilar welding of AISI 409 ferritic stainless steel to AISI 316L austenitic stainless steel by using grey based Taguchi method. Adv Mater Process Technol 4(3):385–401

Ahmed E, Reisgen U, Schleser M, Mokrov O (2013) Biaxial behavior of laser welded DP/TRIP steel sheets. Int J Adv Manuf Technol 68(5):1075–1082

Pramod R, Mohan S, Siva KN, Arungalai Vendan SS (2020) Formability studies on plasma arc welded duplex stainless steel 2205 sheet, Materialwiss. Werkstofftech 51(163):173

Habibi M, Hashemi R, Sadeghi E, Fazaeli A, Ghazanfari A, Lashini H (2016) Enhancing the mechanical properties and formability of low carbon steel with dual-phase microstructures. J Mater Eng Perform 25:382–389

Kumar SM, Shanmugam NS (2019) Finite element simulation for tensile and impact test of activated TIG welding of AISI 321 austenitic stainless steel. Proc Inst Mech Eng Part L J Mater Des Appl 233(11):2323–2334

Alipour M, Torabi MA, Sareban M, Lashini H, Sadeghi E, Fazaeli A, Habibi M, Hashemi R (2020) Finite element and experimental method for analyzing the effects of martensite morphologies on the formability of DP steels. Mech Based Des Struct Mach 48:525–541

Sorce FS, Ngo S, Lowe C, Taylor AC (2019) Quantification of coating surface strains in Erichsen cupping tests. J Mater Sci 54:7997–8009

Martín Ó, De Tiedra P, García C, Martín F, López M (2012) Comparative study between large-scale and small-scale electrochemical potentiokinetic reactivation performed on AISI 316L austenitic stainless steel. Corros Sci 54:119–126

Jang AY, Lee DJ, Lee SH, Shim JH, Kang SW, Lee HW (2011) Effect of Cr/Ni equivalent ratio on ductility-dip cracking in AISI 316L weld metals. Mater Des 32:371–376

Chandrasekar G, Kailasanathan C, Verma DK, Nandagopal K (2017) Optimization of welding parameters, influence of activating flux and investigation on the mechanical and metallurgical properties of activated TIG weldments of AISI 316L stainless steel. Trans Indian Inst Met 70(3):671–684

Elmer JW, Allen SM, Eagar TW (1989) Microstructural development during solidification of stainless steel alloys. Metall Trans 20(10):2117–2131

Ekaputra IMW, Mungkasi S, Haryadi GD, Dewa RT, Kim SJ (2018) The influence of welding speed conditions of GMAW on mechanical properties of 316L austenitic stainless steel. MATEC Web Conf 159:02009

Feng Y, Luo Z, Liu Z, Li Y, Luo Y, Huang Y (2015) Keyhole gas tungsten arc welding of AISI 316L stainless steel. Mater Des 85:24–31

Rajesh Kannan A, Siva Shanmugam N, Arungalai Vendan S (2019) Effect of cold metal transfer process parameters on microstructural evolution and mechanical properties of AISI 316L tailor welded blanks. Int J Adv Manuf Technol 103(9):4265–4282

Sriba A, Vogt J-B, Amara S-E (2018) Microstructure, micro-hardness and impact toughness of welded austenitic stainless steel 316L. Trans Indian Inst Met 71(9):2303–2314

Saha S, Mukherjee M, Pal TK (2015) Microstructure, texture, and mechanical property analysis of gas metal arc welded AISI 304 austenitic stainless steel. J Mater Eng Perform 24(3):1125–1139

Kell J, Tyrer JR, Higginson RL, Thomson RC (2005) Microstructural characterization of autogenous laser welds on 316L stainless steel using EBSD and EDS. J Microsc 217(2):167–173

Hamza S, Boumerzoug Z, Helbert AL, Bresset F, Baudin T (2019) Texture analysis of welded 304L pipeline steel. J Met Mater Miner 29(3):32–41

Kumar SM, Shanmugam NS (2018) Studies on the weldability, mechanical properties and microstructural characterization of activated flux TIG welding of AISI 321 austenitic stainless steel. Mater Res Express 5(10):106524

Mohan Kumar S, Siva Shanmugam N (2020) Effect of heat input and weld chemistry on mechanical and microstructural aspects of double side welded austenitic stainless steel 321 grade using tungsten inert gas arc welding process, Materialwiss. Werkstofftech 51:349–367

Kou S (2003) Welding metallurgy, 2nd edn. Wiley, Hoboken, pp 156–160

Campbell FC (2008) Elements of metallurgy and engineering alloys. ASM International, Materials Park

Rajesh Kannan A, Siva Shanmugam N (2020) Some studies on mechanical properties of AISI 316L austenitic stainless steel weldments by cold metal transfer process. In: Shunmugam MS, Kanthababu M (eds) Advances in additive manufacturing and joining. Springer, Singapore, pp 359–371

Tȕmer M, Yılmaz R (2016) Characterization of microstructure, chemical composition, and toughness of a multipass welded joint of austenitic stainless steel AISI 316L. Int J Adv Manuf Technol 87(9):2567–2579

Xia X, Jiefeng Wu, Liu Z, Haibiao Ji Xu, Shen JM, Zhuang P (2019) Correlation between microstructure evolution and mechanical properties of 50mm 316L electron beam welds. Fusion Eng Des 147:111245

Kim PS, Choi SY, Kim YS, Kim JD (2015) A study on the weldability of INCOLOY 825 alloys and STS316L alloys. Adv Mater Res 1110:118–124

Abbassi F, Belhadj T, Mistou S, Zghal A (2013) Parameter identification of a mechanical ductile damage using artificial neural networks in sheet metal forming. Mater Des 45:605–615

Acknowledgments

The authors gratefully acknowledge the DST-FIST (SR/FST/ETI-421/2016) SEM–EDS facility at IIT Hyderabad, Telangana, used in this work.

Funding

This study was not financially supported by any funding agency.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Technical Editor: Izabel Fernanda Machado.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kannan, A.R., Sankarapandian, S., Pramod, R. et al. Experimental and numerical studies on the influence of formability of AISI 316L tailor-welded blanks at different weld line orientations. J Braz. Soc. Mech. Sci. Eng. 43, 171 (2021). https://doi.org/10.1007/s40430-021-02896-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-021-02896-8