Abstract

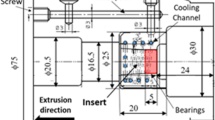

To prevent an overheating of the workpiece material and to increase the productivity in hot aluminum extrusion, the application of extrusion dies with conformal cooling channels manufactured additively by selective laser melting is known. Since, to date, the additive manufacturing processes are often accompanied with higher manufacturing time and costs in comparison to conventional subtractive methods, a new concept for a hybrid extrusion die is presented. Here, the large volume but geometrically simple die part, the die bridge, is manufactured conventionally by subtractive methods, and the smaller part with geometrical complexity, the tip of the mandrel, is built-up on it additively by laser melting. A further novelty of the developed die is the isolated feeding of the coolant up to the target area, close to die bearings, where the cooling shall be localized. Numerical and experimental investigations revealed that the profile’s exit temperature can be reduced locally and controlled which leads only to a moderate increase of the extrusion force. The experimental results show that the hybrid tools withstand the high mechanical and thermal loads which occur during hot aluminum extrusion.

Similar content being viewed by others

References

Schmidt + Clemens Group (2015) Solutions for the extrusion industry, S + C Extrusion Tooling Solutions GmbH, http://www.schmidt-clemens.com/fileadmin/web_images/ Broschueren/ SC_Brochure_ETS_ENG.pdf

Bauser M, Sauer, G, Siegert, K (2006) Extrusion, 2nd edition, ASM International

Schomäcker M (2007) Verbundstrangpressen von Aluminiumprofilen mit endlosen metallischen Verstärkungselementen. Dr.-Ing. Dissertation, Shaker Verlag, Institut für Umformtechnik und Leichtbau, Technische Universität Dortmund

Akeret R (1971) Die Produktivität beim Strangpressen von Aluminium- Werkstoffen – Einfluss von Werkstoff und Verfahren. Z Met 62–6:451–456

Hölker R (2014) Additiv hergestellte Werkzeuge mit lokaler Innenkühlung zur Produktivitätssteigerung beim Aluminium-Strangpressen. Dissertation, Technische Universität Dortmund, Shaker Verlag, Aachen, Dr.-Ing

Akeret R (1980) Das Verhalten der Strangpresse als Regelstrecke. Metall 34–8:737–741

Hölker R, Jäger A, Ben Khalifa N, Tekkaya AE (2013) Controlling heat balance in hot aluminum extrusion by additive manufactured extrusion dies with conformal cooling channels. Int J Precis Eng Manuf 14–8:1487–1493

Menges G, Michaeli W, Mohren P (2001) How to make injection molds, publisher Carl Hanser Verlag GmbH & Co. KG

Ahn DG (2011) Applications of laser assisted metal rapid tooling process to manufacture of molding & forming tools–state of the art. Int J Precis Eng Manuf 12–5:925–938

Emmelmann C, Klahn, C (2012) Funktionsintegration im Werkzeugbau durch laseradditive Fertigung. RTe Journal-Forum für Rapid Technologie 9

Levy GN, Schindel R, Schleiss P, Micari F, Fratini L (2003) On the use of SLS tools in sheet metal stamping. CIRP Ann Manuf Technol 52–1:249–252

Cheah CM, Chua CK, Lee CW, Lim ST, Eu KH, Lin LT (2002) Rapid sheet metal manufacturing–part 2: direct rapid tooling. Int J Adv Manuf Technol 19–7:510–515

Müller B, Neugebauer R, 2010. Direkte generative Fertigung von Schmiedegesenken eröffnet neue Möglichkeiten. In: RTejournal – Forum für Rapid Technologie 7

Huskic A, Behrens B-A, Giedenbacher J, Huskic A (2013) Standzeituntersuchungen generativ hergestellter Schmiedewerkzeuge. SchmiedeJOURNAL 9:66–70

Huskic A, Giedenbacher J, Pschebezin U, Wild, N (2012) Rapid tooling für Umformwerkzeuge. RTejournal-Forum für Rapid Technologie 9-1

Foydl A, Segatori A, Ben Khalifa N, Donati L, Brosius A, Tomesani L, Tekkaya AE (2013) Grain size evolution simulation in aluminium alloys AA 6082 and AA 7020 during hot forward extrusion process. J Mater Sci Technol 29–1:100–110

Hoffmann G (2007) LaserCusing® - Neue innovative Möglichkeiten der Werkzeugtemperierung, Anwendungen und Beispiele aus der Praxis. Zäh M, Reinhart G, IWB Seminarberichte 85:9-1 to 9-17

Kind & Co. (2014) Material data sheet 1.2343, Kind & Co, Edelstahlwerk KG

Böhler (2009) Werkstoffdatenblatt Böhler W722 VMR, Hochfester martensitaushärtender Stahl, Böhler Edelstahl GmbH & Co. KG

Yasa E, Kempen K, Kruth J.-P, Thijs L, Van Humbeeck, J (2010) Microstructure and mechanical properties of maraging steel 300 after selective laser melting. Solid Freeform Fabrication Symposium Proceedings 2010, Austin, Texas, USA, 12.-14. August:383-396

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hölker, R., Tekkaya, A.E. Advancements in the manufacturing of dies for hot aluminum extrusion with conformal cooling channels. Int J Adv Manuf Technol 83, 1209–1220 (2016). https://doi.org/10.1007/s00170-015-7647-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7647-4