Abstract

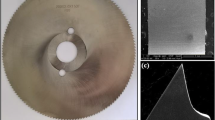

Circular saw blades are fundamental and necessary cutting tools used for sawing, slicing, and related machining processes. In this paper, an innovative and economical design of a circular saw blade with self-clamped cutting inserts used for general purpose steel cutting is presented. The designed circular saw blade consists of a plurality of cutting inserts assembled to a circular saw plate through an elastic deformation-based self-clamping mechanism. Prototypes of the designed circular saw blade were actually fabricated. Slicing tests of workpieces made of JIS S45C carbon steel and JIS SCM440 alloy steel were conducted, and the induced cutting forces and surface roughness were also measured and then evaluated through established response surface models. The resultant cutting forces obtained from all slicing tests were less than 560 N, which indicates that a moderate level of cutting forces would be induced. The values of arithmetical mean roughness obtained from all slicing tests significantly ranged from 1 to 4 μm, which indicates that well surface quality of the machined surface could be achieved. Therefore, the presented circular saw blade was feasible for applications of general purpose steel cutting.

Similar content being viewed by others

References

DeGarmo EP, Black JT, Kohser RA (2003) Materials and processes in manufacturing—9th edn (updated edition). Wiley, Hoboken, p. 228, pp. 645–651

Groover MP (2011) Principles of modern manufacturing—4th edn. Wiley, Hoboken, pp. 369–371, pp. 526–527, pp. 553–556, pp. 566–567

Karnashe Professional Tools GmbH, Catalogue HMS-MKS-MST 25/1. available at: http://www.karnasch.de/mediadb/hms-mks-mst-25-1/catalogue/

Tsune Seiki Co., Ltd. Available at: http://www.tsune.co.jp/english/prodcuts/tools/

Re-Bo REBER GmbH. Available at: http://www.re-bo.com/en/products.html

Walter GmbH. Available at: http://www.walter-saegen.de/en/index.php

Chabrier P, Martin P (1999) An overview of methods for monitoring circular saw blade preparation. Holz als Roh- und Werkstoff 57(3):157–163

Stakhiev YM (2000) Today and tomorrow circular sawblades: Russian version. Holz als Roh- und Werkstoff 58(4):229–240

Nishio S, Marui E (1996) Effects of slots on the lateral vibration of a circular saw blade. Int J Mach Tools Manuf 36(7):771–787

Alam MT, Kinoshita N, Tanaka C, Yoshinobu M (2002) Circular saw lateral stability by optimization of feed speed. Holz als Roh- und Werkstoff 60(3):207–209

Orlowski K, Sandak J, Tanaka C (2007) The critical rotational speed of circular saw: simple measurement method and its practical implementations. J Wood Sci 53(5):388–393

Reiter WF Jr, Keltie RF (1976) On the nature of idling noise of circular saw blades. J Sound Vib 44(4):531–543

Hattori N, Iida T (1999) Idling noise from circular saws made of metals with different damping capacities. J Wood Sci 45(5):392–395

Beljo-Lučić R, Goglia V (2001) Some possibilities for reducing circular saw idling noise. J Wood Sci 47(5):389–393

Bradbury SR, Lewis DB (2000) A comparison of the performance and wear characteristics of high-speed steel circular saw blades machining Nimonic PK31, AISI O1 tool steel, Inconel 600L, and AISI 1018 carbon steel. J Mater Sci 35(6):1511–1524

Pospiech J (1926) Insertable saw tooth for circular-saw blades. US Patent 1608182

Shone AK (1968) Insertable saw tooth for circular-saw blades. US Patent 3372719

Reed JK (1978) Carbide tipped insertable saw tooth. US Patent 4084470

Wright JL (1988) Rotary machining tool and method of its manufacture. US Patent 4744278

Ludwig AM (1988) Insertable saw tooth. US Patent 4765217

Tuomaala JAK (1989) Mounting of the circularly fitted inserted tooth of a circular saw. US Patent 4885968

Wiemann HJ (1993) Cutting insert holder for circular saw blade. Deutschland Patent 4137497

Benz G (1998) Saw disk. US Patent 5829423

Arntz JW, Huelmann E (1999) Saw blade with insert clamping device. Deutschland Patent 19735143

Seco Tools AB (2014) Catalogue of milling cutters. Available at: http://www.secotools.com/CorpWeb/Downloads/seconews2014_2/mn/GB_Catalog_Milling_2014_LR.pdf

Iscar Ltd. Slitting cutters. Available at: http://www.iscar.com/Products.aspx/CountryID/1/ProductId/3702

Goellner WJ (1987) Circular saw. US Patent 4463645

Johnson JL, Runyon G, Morton C (2008) Powder power. Cutting Tool Eng Magazine 60(2) available at: http://www.ctemag.com/pdf/2008/0802-Tungsten.pdf

Mitsubishi Material Corp. General catalogue C006b (2013–2014). Available at: http://www.mitsubishicarbide.com/mmc/en/product/pdf/catalog/c006b.pdf

Sumitomo Electric Hardmetal Corp. 2014 general catalogue. Available at: http://www.sumitomotool.com/index.php?id=174

TaeguTec Ltd. Metal cutting tools (catalogue). Available at: http://www.taegutec.com/Ustyles/DownloadFiles/All_en.pdf

Boehlerit GmbH & Co KG. Tungsten carbide finished and semi-finished products. Available at: http://www.bohler.nl/dutch/files/downloads/Boehlerit_voorbewerkte_delen_en_gerede_producten.pdf

Honeycombe RWK, Bhadeshia HKDH (1995) Steels: microstructure and properties—2nd edn. Butterworth-Heinemann, Oxford

JFE Steel Corp. Special steel sheet. Available at: http://www.jfe-steel.co.jp/en/products/sheets/catalog/b1e-005.pdf

Nippon Steel & Sumitomo Metal Corp. Special steel sheets and coils. Available at: http://www.nssmc.com/product/catalog_download/pdf/U006en.pdf

Banerjee S, Mahapatro D, Dubey S (2009) Some study on electrical discharge machining of ({WC+TiC+TaC/NbC}−Co). Int J Adv Manuf Technol 43(11–12):1177–1188

Chang WT, Su CH, Guo DX, Tang GR, Shiou FJ (2013) Automated optical inspection for the runout tolerance of circular saw blades. Int J Adv Manuf Technol 66(1–4):565–582

Kluft W, Konig W, Lutterwelt CA, Nagayama K, Pekelharing AJ (1979) Present knowledge of chip form. CIRP Ann 28(2):441–455

The MathWorks Inc. (1999) MATLAB statistics toolbox user’s guide—version 2. The MathWorks Inc., Natick

Lee ES, Hwang SC, Lee JT, Won JK (2009) A study on the characteristic of parameters by the response surface method in final wafer polishing. Int J Precis Eng Manuf 10(3):25–30

Yoon HS, Wu R, Lee TM, Ahn SH (2011) Geometric optimization of micro drills using Taguchi methods and response surface methodology. Int J Precis Eng Manuf 12(5):871–875

Zębala W, Kowalczyk R (2015) Estimating the effect of cutting data on surface roughness and cutting force during WC-Co turning with PCD tool using Taguchi design and ANOVA analysis. Int J Adv Manuf Technol 77(9–12):2241–2256

Aggarwal V, Khangura SS, Garg RK (2015) Parametric modeling and optimization for wire electrical discharge machining of Inconel 718 using response surface methodology. Int J Adv Manuf Technol 79(1–4):31–47

Sun Y, Zhang Z, Zhang J, Jin X, Xu B, Zhao G (2015) Cutting force models for Fe–Al-based coating processed by a compound NC machine tool. Int J Adv Manuf Technol 79(1–4):693–704

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chang, WT., Chen, LC. Design and experimental evaluation of a circular saw blade with self-clamped cutting inserts. Int J Adv Manuf Technol 83, 365–379 (2016). https://doi.org/10.1007/s00170-015-7563-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-7563-7