Abstract

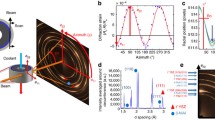

The x-ray method is used to determine residual macrostresses in the surface layer of protective coatings on high-temperature alloys. Coatings deposited by the high-energy vacuum-plasma (HEVP) method were subjected to diffusion annealing and mechanical treatment. The calculated and experimental values of residual thermal stresses in the coatings are compared.

Similar content being viewed by others

References

P. T. Kolomytsev,High-Temperature Protective Coatings for Nickel Alloys [in Russian], Metallurgiya, Moscow (1991).

N. V. Abraimov,High-Temperature Materials and Coatings for Gas Turbines [in Russian], Mashinosroenie, Moscow (1993).

B. E. Paton, G. B. Stroganov, S. T. Kishkin, et al.,High-Temperature Strength of Nickel Alloys and Their Protection from Oxidation [in Russian], Naukova Dumka, Kiev (1987).

Yu. D. Yagodkin and V. S. Terent'eva, “Heat-resistant coatings,”Itogi Nauki Tekhn., Ser. Metalloved. Termich. Obrab.,25, 182–253 (1991).

S. A. Muboyadhzyan, E. N. Kablov, and S. A. Budinovskii, “Vacuum plasma technology for manufacturing protective coatings from complexly alloyed alloys,”Metalloved. Term. Obrab. Met., No. 2, 15–18.

E. N. Kablov, S. A. Muboyadzhyan, A. M. Sulima, et al., “Prospects for ion treatment in aircraft engineering,”Aviats. Prom-st., No. 9, 9–12 (1992).

S. A. Muboyadzhyan and S. A. Budinovskii, “Condensation and condensation-diffusion coatings for gas-turbine blades from high-temperature alloys with a directed crystal structure,”Metalloved. Term. Obrab. Met., No. 4, 15–18 (1996).

D. M. Vasil'ev and B. B. Trofimov, “Current state of the x-ray method for measuring macrostresses,”Zavod. Lab., No. 7, 20–29 (1984).

R. Delhez, Th. Keijser, and E. Mittemeir, “Role of x-ray diffraction analysis in surface engineering: Investigation of microstructure of nitrided iron and steels,”Surf. Eng.,3(4), 331–342 (1987).

D. M. Kheiker and L. S. Zevin,X-Ray Diffractometry [in Russian], Fizmatgiz, Moscow (1973).

Yu. D. Yagodkin, “An x-ray study of the structure of a surface layer by the method of scanning reflected beam,”Zavod. Lab.,55(2), 72–73 (1989).

A. N. Ivanov, E. I. Fomicheva, and E. V. Shelekhov, “Use of a scanning beam for studying surface layers with the help of a general-purpose x-ray diffractometer,”Zavod. Lab., No. 12, 41–47 (1989).

T. Ya. Kosolapova (ed.),Properties, Production, and Use of Refractory Compounds [in Russian], Metallurgiya, Moscow (1986).

A. M. Sulima, V. A. Shulov, and Yu. D. Yagodkin,The Surface Layer and Operational Properties of Machine Parts [in Russian], Mashinostroenie, Moscow (1988).

S. A. Muboyadzhyan, S. A. Budinovskii, Yu. D. Yagodkin, et al. “Effect of precipitation process parameters on the structure of ion-plasma coatings,” in:Modifying the Properties of Structural Materials by Beams of Charged Particles. Abstr. Rep. 3rd Conf., Part 2 [in Russian], ISÉ SO RAN, Tomsk (1994), pp. 146–149.

Designs and Tests for Strength in Mechanical Engineering. Test Methods for High-Temperature Coatings for Gas-Turbine Blades [in Russian], Goskom. SSSR po Standartam, Moscow (1989).

S. R. J. Saunders and J. R. Nicholls, “Coatings and surface treatment for high temperature oxidation resistance,”Mater. Sci. Eng.,5(8), 780–792 (1989).

O. P. Solonina and S. T. Glazunov,Titanium Alloys. High-Temperature Titanium Alloys [in Russian], Metallurgiya, Moscow (1976).

A. Taylor and R. Floyd, “The constitution of nickel-rich alloys of the nickel-chromium-aluminium system,”J. Inst. Met.,81, 451–470 (1952/1953).

K. J. Smithles,Metals [Russian translation], Metallurgiya, Moscow (1980).

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 30–34, November, 1997.

Rights and permissions

About this article

Cite this article

Yagodkin, Y.D., Pastukhov, K.M., Milyaeva, E.V. et al. An X-ray study of residual macrostresses in protective coatings for gas-turbine blades. Met Sci Heat Treat 39, 484–488 (1997). https://doi.org/10.1007/BF02469118

Issue Date:

DOI: https://doi.org/10.1007/BF02469118