Abstract

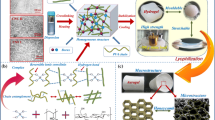

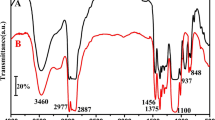

Fatty acids and bamboo fiber (BF) are abundant and renewable materials that have great potential application in the production of high-valued chemical products. In this work, polyurethane foams (PUFs) with remarkable mechanical and thermal properties were synthesized using OAPs (polyols-based on oleic acid (OA), an important fatty acid) and polymeric isocyanates. PUFs were reinforced with BF. Novel OAPs were prepared from OA through a process consisting of hydroxylation, carboxylation, and esterification. The strategy afforded branched polyols with high content of primary hydroxyls. Phthalic anhydride was used as a modifying agent to improve the properties of OAPs. Physicochemical properties of the polyols were characterized by standard methods (analyses of hydroxyl number, viscosity, acid value, density, and water content) and instrumental analysis (gel permeation chromatography, Fourier transform infrared spectroscopy, and thermogravimetry). The mechanical properties of polyurethane foams made from the OAPs were improved by applying modified BF as filler. With BF having particle sizes of 250–500 μm, the compressive strength of composite foams increased from 0.45 to 0.66 MPa, and the flexural strength increased from 0.66 to 0.77 MPa. Surface modification of BF by alkali could enhance the interfacial interaction between the reinforcing fibers and foam matrix, resulting in greater mechanical strength of the PUFs. It also improved the thermal stability and dynamic thermomechanical properties of PUFs.

Similar content being viewed by others

References

Zhang CQ, Kessler MR (2015) Bio-based polyurethane foam made from compatible blends of vegetable-oil-based polyol and petroleum-based polyol. ACS Sustain Chem Eng 3:743–749

Lim H, Kim SH, Kim BK (2008) Effects of the functionality of polyol in rigid polyurethane foams. J Appl Polym Sci 110:49–54

Höfer R, Bigorra J (2004) Biomass-based green chemistry: sustainable solutions for modern economies. Green Chem Lett Rev 1:79–97

Xu JM, Jiang JC, Hse CY, Shupe TF (2014) Preparation of polyurethane foams using fractionated products in liquefied wood. J Appl Polym Sci 131:40096

Biermann U, Bornscheuer U, Meier MA, Metzger JO, Schafer HJ (2011) Oils and fats as renewable raw materials in chemistry. Angew Chem Int Edit 50:3854–3871

Meier MAR, Metzger JO, Schubert US (2007) Plant oil renewable resources as green alternatives in polymer science. Chem Soc Rev 36:1788–1802

Ji D, Fang Z, He W, Luo Z, Jiang X, Wang T (2015) Polyurethane rigid foams formed from different soy-based polyols by the ring opening of epoxidised soybean oil with methanol, phenol, and cyclohexanol. Ind Crop Prod 74:76–82

Zieleniewska M, Leszczynski MK, Kuranska M, Prociak A, Szczepkowski L, Krzyzowska M, Ryszkowska J (2015) Preparation and characterisation of rigid polyurethane foams using a rapeseed oil-based polyol. Ind Crop Prod 74:887–897

Tan SQ, Abraham T, Ference D, Macosko CW (2011) Rigid polyurethane foams from a soybean oil-based polyol. Polymer 52:2840–2846

Septevani AA, Evans DAC, Chaleat C, Martin DJ, Annamalai PK (2015) A systematic study substituting polyether polyol with palm kernel oil based polyester polyol in rigid polyurethane foam. Ind Crop Prod 66:16–26

de Souza VH, Silva SA, Ramos LP, Zawadzki SF (2012) Synthesis and characterization of polyols derived from corn oil by epoxidation and ozonolysis. J Am Oil Chem Soc 89:1723–1731

Desroches M, Escouvois M, Auvergne R, Caillol S, Boutevin B (2012) From vegetable oils to polyurethanes: synthetic routes to polyols and main industrial products. Polym Rev 52:38–79

Kiatsimkul P, Suppes GJ, Hsieh FH, Lozada Z, Tu YC (2008) Preparation of high hydroxyl equivalent weight polyols from vegetable. Ind Crop Prod 27:257–264

Petrovic ZS (2008) Polyurethanes from vegetable oils. Polym Rev 48:109–155

Tran P, Graiver D, Narayan R (2005) Ozone-mediated polyol synthesis from soybean oil. J Am Oil Chem Soc 82:653–659

Piszczyk L, Hejna A, Formela K, Danowska M, Strankowski M (2015) Effect of ground tire rubber on structural, mechanical and thermal properties of flexible polyurethane foams. Iran Polym J 24:75–84

Kim SH, Park HC, Jeong HM, Kim BK (2010) Glass fiber reinforced rigid polyurethane foams. J Mater Sci 45:2675–2680

Shen T, Lu M, Liang L, Zhou D (2012) Influence of blocked polyisocyanate on the mechanical, thermal and interfacial properties of bamboo/hydroxyl-terminated polyurethane composites. Iran Polym J 21:1–9

Paberza A, Cabulis U, Arshanitsa A (2014) Wheat straw lignin as filler for rigid polyurethane foams on the basis of tall oil amide. Polimery 59:477–481

Tay GS, Ong LN, Rozman HD (2012) Mechanical properties and fire retardant behavior of polyurethane foam reinforced with oil palm empty fruit bunch. J Appl Polym Sci 125:158–164

Wang HJ, Zhang CY, Rong MZ, Zhang MQ, Czigány T (2008) Interfacial effects in short sisal fiber/maleated castor oil foam composites. Compos Interface 15:95–110

Zhao Y, Qiu J, Feng H, Zhang M (2012) The interfacial modification of rice straw fiber reinforced poly(butylene succinate) composites: effect of aminosilane with different alkoxy groups. J Appl Polym Sci 125:3211–3220

Xu JM, Jiang JC, Li J (2012) Preparation of polyester polyol from unsaturated fatty acid. J Appl Polym Sci 126:1377–1384

Ismail TNMT, Palam KDP, Bakar ZBA, Soi HS, Kian YS, Hassan HA, Schiffman C, Sendijarevic A, Sendijarevic V, Sendijarevic IJ (2016) Urethane-forming reaction kinetics and catalysis of model palm olein polyols: quantified impact of primary and secondary hydroxyls. J Appl Polym Sci 133:42955

Sluiter AD, Hames BR, Ruiz RO, Scarlata C, Sluiter JB, Templeton DW, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory analytical procedure technical report: NREL/TP-510-42618

Ionescu M, Petrovic ZS, Wan X (2010) Ethoxylated soybean polyols for polyurethanes. J Polym Environ 18:1–7

Gu R, Sain MM (2013) Effects of wood fiber and microclay on the performance of soy based polyurethane foams. J Polym Environ 21:30–38

Fan H, Tekeei A, Suppes GJ, Hsieh FH (2012) Properties of biobased rigid polyurethane foams reinforced with fillers: microspheres and nanoclay. Int J Polym Sci 2012:474803

Zhu M, Bandyopadhyay Ghosh S, Khazabi M, Cai H, Correa C, Sain M (2012) Reinforcement of soy polyol-based rigid polyurethane foams by cellulose microfibers and nanoclays. J Appl Polym Sci 124:4702–4710

Da Silva VR, Mosiewicki MA, Yoshida MI, Da Siva MC, Stefani PM, Marcovich NE (2013) Polyurethane foams based on modified tung oil and reinforced with rice husk ash I: synthesis and physical chemical characterization. Polym Test 32:438–445

Gu R, Khazabi M, Sain M (2011) Fiber reinforced soy-based polyurethane spray foam insulation. Part 2: thermal and mechanical properties. BioResources 6:3775–3790

Acknowledgments

The authors acknowledge the financial grant received from Special Fund for Forestry-Scientific Research in the Public Interest of China (201504602) for supporting the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, J., Jiang, J., Xu, J. et al. Branched polyols based on oleic acid for production of polyurethane foams reinforced with bamboo fiber. Iran Polym J 25, 811–822 (2016). https://doi.org/10.1007/s13726-016-0469-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-016-0469-x