Abstract

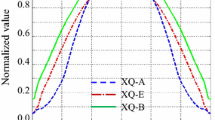

This paper presents the design and fabrication of a light emitting diode-based light guide plate to realize the diffuser sheet-less applications for an indoor lighting. The diffuser sheet has been used for distributing the luminous intensity in uniform over the target n area, but it leads to light loss and production cost. Here, a diffuser sheet-less LGP with high luminous efficiency and high spatial uniformity was designed by a Monte-Carlo ray tracing method and fabricated by an ultraprecision machining. Simulation results showed that the U-groove LGP has great potential to get rid of the diffuser sheet: efficiency of 70.5% (lm/lm) and uniform luminous intensity distribution of 145 at a viewing angle (C = 0) and 120 at a viewing angle (C = 90), respectively. From the measurement results, it agreed with the simulation results. Thus, it was confirmed that the proposed LGP shows a good performance in terms of efficiency and a wide luminous intensity distribution, and a possibility to substitute for a diffuser-based illumination system.

Similar content being viewed by others

References

Chang, J. G. and Lee, C. T., “Random-dot pattern design of a light guide in an edge-lit backlight: integration of optical design and dot generation scheme by the molecular-dynamics method,” J. Opt. Soc. Am. A, Vol. 24, No. 3, pp. 839–849, 2007.

Goto, Y., “Light guide plate and surface light source using the light guide plate,” US Patent, No. 5999685, 1999.

Funamoto, A. and Aoyama, S., “LED backlight system with doubleprism pattern,” J. Soc. Inf. Disp., Vol. 14, No. 11, pp. 1045–1051, 2006.

Chang, S. I., Yoon, J. B., Kim, H. K., Kim, J. J., Lee, B. K., and Shin, D. H., “Microlens array diffuser for a light-emitting diode backlight system,” Opt. Lett., Vol. 31, No. 20, pp. 3016–3018, 2006.

Joo, J. Y., Woo, D. K., Park, S. S., and Lee, S. K., “Design and fabrication of a fingerprint imager with compact LED illumination and compact imaging optics,” Opt. Express, Vol. 18, No. 18, pp. 18932–18944, 2010.

Joo, J. Y., Kang, C. S., Park, S. S., and Lee, S. K., “LED beam shaping lens based on the near-field illumination,” Opt. Express, Vol. 17, No. 26, pp. 23449–23458, 2009.

Joo, J. Y. and Lee, S. K., “Miniaturized TIR Fresnel lens for miniature optical LED applications,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 2, pp. 137–140, 2009.

Backlight, www.en.wikipedia.org/wiki/light_guide_plate

Park, S. R., Kwon, O. J., Shin, D. H., and Song, S. H., “Grating micro-dot patterned light guide plates for LED backlights,” Opt. Express, Vol. 15, No. 6, pp. 2888–2899, 2007.

Parikka, M., Kaikuranta, T., Laakkonen, P., Tauyanen, J, Tervo, J., Honkanen, M., Kuittnen, M., and Turunen, J., “Determistic diffractive diffusers for display,” Appl. Opt., Vol. 40, pp. 2239–2246, 2001.

Ochiai, S. I., “Light guide plate and light guide plate assembly utilizing diffraction grating,” US Patent, No. 5703667, 1997.

Nussbaum, P., Philipoussis, I., Husser, A., and Herzig, H. P., “Simple technique for replication of micro optical elements,” Opt. Eng., Vol. 37, pp. 1804–1808, 1998.

Park, S. H., Shin, Y. J., Choi, E. S., Ma, H. J., and Lee, S. S., “Improvement of luminance and uniformity of light guide panel using scatterer pattern by laser processing,” Opt. Laser Technol., Vol. 44, pp. 1301–1306, 2012.

Käläntär, K., “A directional backlight with narrow angular luminance distribution for widening the viewing angle for an LCD with a front-surface light-scattering film,” J. Soc. Inf. Disp., Vol. 20, No. 3, pp. 133–142, 2012.

Lee, C. B., Kuriyagawa, T., Woo, D. K., and Lee, S. K., “Optimizing the fabrication process of a high-efficiency blazed grating through diamond scribing and molding,” J. Micromech. Microeng., Vol. 20, No. 5, Paper No. 055028, 2010

Lee, C. B, Hane, K., and Lee, S. K., “The optimization of sawtooth gratings using RCWA and its fabrication on a slanted silicon substrate by fast atom beam etching,” J. Micromech. Microeng., Vol. 18, No. 14, Paper No. 045012, 2008.

Woo, D., K., Hane, K., and Lee, S. K., “High order diffraction grating using V-shaped groove with refractive and reflective surfaces,” Opt. Express, Vol. 16, pp. 21004–21011, 2008.

Lee, C. B., Kim, G. H., and Lee, S. K., “Uncertainty investigation of grating interferometry in six degree-of-freedom motion error measurements,” Int. J. Precis. Eng. Manuf., Vol. 13, No. 9, pp. 1509–1515, 2012.

Hwang, Y., Kuriyagawa, T., and Lee, S. K., “Wheel curve generation error of aspheric microgrinding in parallel grinding method,” Int. J. Mach. Tools Manuf., Vol. 6, No. 1, pp. 59–64, 2006.

Pang, C. T., Wu, T. T., Liu, Y. T., Yamagata, Y., and Huang, J. C., “Fabrication of aspheric surface using ultraprecision cutting and BMG molding,” J. Mater. Process. Technol., Vol. 209, No. 11, pp. 5014–5023, 2009.

Yan, J., Oowada, T., Zhou, T., and Kuriyagawa, T., “Precision machining of microstructures on electroless-plated NIP surface for molding glass compounds,” J. Mater. Process. Technol., Vol. 209, No. 10, pp. 4802–4808, 2009.

Kim, G. D., and Loh, B. G., “An ultrasonic elliptic vibration cutting device for micro V-groove machining: Kinematical analysis and micro V-groove machining characteristics,” J. Mater. Process. Technol., Vol. 190, No. 1–3, pp. 181–188, 2009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, Y.K., Joo, JY., Lee, C. et al. Design and fabrication of a light emitting diode-based diffuser sheet-less light guide plate for lighting applications. Int. J. Precis. Eng. Manuf. 14, 1017–1022 (2013). https://doi.org/10.1007/s12541-013-0136-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-013-0136-5