Abstract

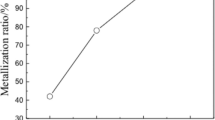

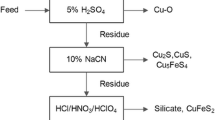

Copper slag was subjected to in-depth mineralogical characterization by integrated instrumental techniques and evaluated for the efficacy of physical beneficiation and mixed meso-acidophilic bioleaching tests towards recovery of copper. Point-to-point mineral chemistry of the copper slag is discussed in detail to give better insight into the association of copper in slag. Characterization studies of the representative sample revealed the presence of fayalite and magnetite along with metallic copper disseminated within the iron and silicate phases. Physical beneficiation of the feed slag (~0.6% Cu) in a 2 L working volume flotation cell using sodium isopropyl xanthate resulted in Cu beneficiation up to 2–4% and final recovery within 42–46%. On the other hand, a mixed meso-acidophilic bacterial consortium comprised of a group of iron and/or sulfur oxidizing bacteria resulted in enhanced recovery of Cu (~92–96%) from the slag sample. SEM characterization of the bioleached slag residue also showed massive coagulated texture with severe weathered structures. FE-SEM elemental mapping with EDS analysis indicated that the bioleached residues were devoid of copper.

Similar content being viewed by others

References

S. Panda, K. Sanjay, L. B. Sukla, N. Pradhan, T. Subbaiah, B.K. Mishra, M. S.R. Prasad and S. K. Ray, Hydrometallurgy, 125–126, 157 (2012).

S. Panda, C.K. Sarangi, N. Pradhan, T. Subbaiah, L.B. Sukla, B.K. Mishra, G.L. Bhatoa, M. S.R. Prasad and S. K. Ray, Korean J. Chem. Eng., 26, 781 (2012).

C. Shi, C. Meyer and A. Behnood, Resour. Conserv. Recycl., 52, 1115 (2008).

X. Liu and N. Zhang, Waste Manage. Res., 29, 1053 (2011).

B. Gorai, R.K. Jana and Premchand, Resour. Conserv. Recycl., 39, 299 (2003).

S. Anand, P. K. Rao and P. K. Jena, Hydrometallurgy, 5, 355 (1980).

A. N. Banza, E. Gock and E. Kongolo, Hydrometallurgy, 67, 63 (2003).

W. J. Bruckard, M.H. Somerville and F. Hao, Miner. Eng., 17, 495 (2004).

T. Deng and Y. Ling, Waste Manage. Res., 25, 440 (2007).

H. S. Altundogan, H. Boyrazli and F. Tumen, Miner. Eng., 17, 465 (2004).

C. Arslan and F. Arslan, Hydrometallurgy, 67, 1 (2002).

J. Esther, S. Panda, S.K. Behera, L. B. Sukla, N. Pradhan and B. K. Mishra, Bioresour. Technol., 146, 762 (2013).

S. Panda, P.K. Parhi, B.D. Nayak, N. Pradhan, U. B. Mohapatra and L. B. Sukla, Bioresour. Technol., 130, 332 (2013).

S. Ilyas, J.C. Lee and R. Chi, Hydrometallurgy, 131–132, 138 (2013).

T. Yang, Z. Xu, J. Wen and L.Yang, Hydrometallurgy, 97, 29 (2009).

W. Krebs, R. Bachofen and H. Brandl, Hydrometallurgy, 59, 283 (2001).

Q. Wang, J. Yang, Q. Wang and T. Wu, J. Hazard. Mater., 162, 812 (2009).

Y. Qu, B. Lian, B. Mo and C. Liu, Hydrometallurgy, 136, 71 (2013).

E. Rudnik and M. Nikiel, Hydrometallurgy, 89, 61 (2007).

S. Mishra, P.P. Panda, N. Pradhan, D. Satapathy, U. Subudhi, S.K. Biswal and B. K. Mishra, Fuel, 117, 415 (2014).

R. N. Kumar and R. Nagendran, J. Hazard. Mater., 169, 1119 (2009).

S. Panda, P.K. Parhi, N. Pradhan, U.B. Mohapatra, L.B. Sukla and K.H. Park, Hydrometallurgy, 121–124, 116 (2012).

S. Panda, P.C. Rout, C.K. Sarangi, S. Mishra, N. Pradhan, U.B. Mohapatra, T. Subbaiah, L.B. Sukla and B. K. Mishra, Korean J. Chem. Eng., 31, 452 (2014).

B. Das, S. Prakash, S. K. Angadi, P. S.R. Reddy and B. K. Mishra, Report No. T/MP/647/March/2008, IMMT, Bhubaneswar, an Internal Report.

B. Fu, H. Zhou, R. Zhang and G. Qiu, Int. Biodeter. Biodegrad., 62, 109 (2008).

M. P. Silverman and D. G. Lundgren, J. Bacteriol., 77, 642 (1959).

S. Panda, N. Pradhan, U.B. Mohapatra, S. K. Panda, S. S. Rath, B.D. Nayak, D. S. Rao, L.B. Sukla and B.K. Mishra, Front. Env. Sci. Eng., 7, 281 (2013).

W. Sand, T. Gehrke, P. G. Jozsa and A. Schippers, Hydrometallurgy, 59, 159 (2001).

H. Tributsch, Hydrometallurgy, 59, 177 (2001).

F. Carranza, R. Romero, A. Mazuelos, N. Iglesias and O. Forcat, Hydrometallurgy, 97, 39 (2009).

H. Zhao, J. Wang, M. Hu, W. Qin, Y. Zhang and G. Qui, Bioresour. Technol., 149, 71 (2013).

E. A. Vestola, M. K. Kuusenaho, H. M. Närhi, O. H. Tuovinen, J.A. Puhakka and J. J.A. H. Kaksonen, Hydrometallurgy, 103, 74 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Panda, S., Mishra, S., Rao, D.S. et al. Extraction of copper from copper slag: Mineralogical insights, physical beneficiation and bioleaching studies. Korean J. Chem. Eng. 32, 667–676 (2015). https://doi.org/10.1007/s11814-014-0298-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-014-0298-6