Abstract

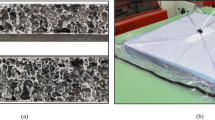

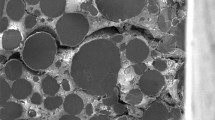

Composite sandwich structures with honeycomb cores show varying properties in geometry and mechanical behavior depending on the studied scale. Herein a new test and evaluation method for sub-surface core damage in the indentation area of honeycomb sandwich structures using computed tomography is presented. The combination of X-ray micro-computed tomography (X-μCT) and an image analysis procedure adjusted to the detection of core deformation mechanisms allows the extraction and quantification of externally invisible, sub-surface damage in the sandwich composite. For this specific contact or indentation loading case on the sandwich face sheet an in-situ device is introduced, enabling a 3D analysis of the structural change during progressing indentation depth.

Similar content being viewed by others

References

Olsson R, McManus HL (1996) Improved theory for contact indentation of sandwich panels. AIAA J 34(6):1238–1244

Olsson R (2002) Engineering method for prediction of impact response and damage in sandwich panels. J Sandw Struct Mater 4(1):3–29

Petras A, Sutcliffe M (1999) Indentation resistance of sandwich beams. Compos Struct 46(4):413–424

Swanson SR, Kim J (2003) Design of sandwich structures under contact loading. Compos Struct 59(3):403–413

Foo CC, Chai GB, Seah LK (2008) A model to predict low-velocity impact response and damage in sandwich composites. Compos Sci Technol 68(6):1348–1356

Foo CC, Seah LK, Chai GB (2008) Low-velocity impact failure of aluminium honeycomb sandwich panels. Compos Struct 85(1):20–28

Tan K, Watanabe N, Iwahori Y (2011) X-ray radiography and microcomputed tomography examination of damage characteristics in stitched composites subjected to impact loading. Compos Part B 42(4):874–884

Bull D, Helfen L, Sinclair I, Spearing S, Baumbach T (2013) A comparison of multi-scale 3d x-ray tomographic inspection techniques for assessing carbon fibre composite impact damage. Compos Sci Technol 75:55–61

Davies P, Choqueuse D, Bourbouze G (2011) Micro-tomography to study high-performance sandwich structures. J Sandw Struct Mater 13(1):7–21

T. Liu, A.A. Malcolm, J. Xu, in 2nd International Symposium on DNT in Aerospace 2010 (2010)

Dietrich S, Weidenmann K, Elsner P (2014) 3d tomographic characterization of sandwich structures. NDT & E International 62:77–84

Bay BK (2008) Methods and applications of digital volume correlation. The J of Strain Analysis for Engineering Design 43(8):745–760

Forsberg F, Sj¨odahl M, Mooser R, Hack E, Wyss P (2010) Full threedimensional strain measurements on wood exposed to three-point bending: Analysis by use of digital volume correlation applied to synchrotron radiation micro-computed tomography image data. Strain 46(1):47–60

M. Gates, J. Lambros, M.T. Heath (2011) Towards high performance digital volume correlation, Experimental Mechanics 51(4), 491–507 26 Stefan Dietrich et al

Limodin N, Rthor J, Buffire JY, Hild F, Roux S, Ludwig W, Rannou J, Gravouil A (2010) Influence of closure on the 3d propagation of fatigue cracks in a nodular cast iron investigated by x-ray tomography and 3d volume correlation. Acta Mater 58(8):2957–2967

Roux S, Hild F, Viot P, Bernard D (2008) Three-dimensional image correlation from x-ray computed tomography of solid foam. Compos A: Appl Sci Manuf 39(8):1253–1265

Viot P, Plougonven E, Bernard D (2008) Microtomography on polypropylene foam under dynamic loading: 3d analysis of bead morphology evolution. Compos A: Appl Sci Manuf 39(8):1266–1281

Buffiere JY, Maire E, Adrien J, Masse JP, Boller E (2010) In situ experiments with x ray tomography: an attractive tool for experimental mechanics. Exp Mech 50(3):289–305

Brault R, Germaneau A, Dupr J, Doumalin P, Mistou S, Fazzini M (2013) In-situ analysis of laminated composite materials by x-ray microcomputed tomography and digital volume correlation. Exp Mech 53(7):1143–1151

Kuppinger J, Weidenmann K, Kordick M, Wafzig F, Henning F, Elsner P (2010) Influence of fibre length and concentration on the mechanical properties of long glass fibre reinforced polyurethane. J of Plastics Technology 5:205–227

Kuppinger J, Weidenmann K, Haspel B, Wafzig F, Hennig F, Elsner P (2011) Influence of processing conditions, fiber contents and fiber lengths on fiber orientation in the polyurethane fiber spraying process. J of Plastics Technologies 6:44–65

DIN 53291 - Druckversuch senkrecht zur Deckschichtebene (1982)

DIN 53292 - Zugversuch senkrecht zur Deckschichtebene (1982)

DIN 65469 - Faserverst¨arkte Kunststoffe - Zugversuch an einlagigen Zugflachprobek¨orpern (1992)

DIN 844 - Harte Schaumstoffe - Bestimmung der Druckeigenschaften (2009)

Feldkamp LA, Davis LC, Kress JW (1984) Practical cone-beam algorithm. J Opt Soc Am A 1(6):612–619

B. J¨ahne, Image processing for scientific applications (CRC press Boca Raton, 1997)

Schneider CA, Rasband WS, Eliceiri KW et al (2012) Nih image to imagej: 25 years of image analysis. Nat Methods 9(7):671–675

Otsu N (1975) A threshold selection method from gray-level histograms. Automatica 11(285–296):23–27

B. J¨ahne, Digitale Bildverarbeitung (Springer DE, 2005)

Sahoo P, Wilkins C, Yeager J (1997) Threshold selection using renyi’s entropy. Pattern Recogn 30(1):71–84

T.S. Yoo, M.J. Ackerman, W.E. Lorensen, W. Schroeder, V. Chalana, S. Aylward, D. Metaxas, R. Whitaker (2002), Engineering and algorithm 28 Stefan Dietrich et al. design for an image processing api: a technical report on itk-the insight toolkit, Studies in Health Technology and Informatics pp. 586–592

Zhou D, Stronge W (2006) Low velocity impact denting of {HSSA} lightweight sandwich panel. Int J Mech Sci 48(10):1031–1045

Acknowledgments

The authors wish to thank Dr.-Ing. Jan Kuppinger for manufacturing and providing the sandwich composite panels investigated herein.

These investigations were carried out through the research activities of the KITe hyLITE Plus project. This project is funded by the European Union through the program European Funds for Regional Development as well as state government of Baden-Württemberg in Germany.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(GIF 107 kb)

Rights and permissions

About this article

Cite this article

Dietrich, S., Koch, M., Elsner, P. et al. Measurement of Sub-Surface Core Damage in Sandwich Structures Using In-situ Hertzian Indentation During X-ray Computed Tomography. Exp Mech 54, 1385–1393 (2014). https://doi.org/10.1007/s11340-014-9902-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-014-9902-2