Abstract

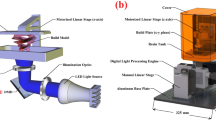

As demands for complex microstructures with high aspect ratios have increased, the existing methods, MEMS and LIGA, have had difficulties coping with the number of masks and fabricable heights. A microstereolithography technology can meet these demands because it has no need of masks and is capable of fabricating high aspect ratio microstructures. In this technology, 3D part is fabricated by stacking layers, 2D sections, which are sliced from STL file, and the Dynamic Image Projection process enables the resin surface to be cured by a dynamic image generated with DMD™ (Digital Micromirror Device) and one irradiation. In this paper, we address optical design process for implementing this microstereolithography system that takes the light path based on DMD operation and image-formation on the resin surface using an optical design program into consideration. To verify the performance of this implemented microstereolithography system, complex 3D microstructures with high aspect ratios were fabricated.

Similar content being viewed by others

References

Bertsch, A., Jezequel, J. Y. and Andre, J. C., 1997, “Study of the Spatial Resolution of a New 3D Microfabrication Process: the Microstereophotolithography Using a Dynamic Mask-Generator Technique,”Journal of Photochemistry and Photobiology A: Chemistry 107, pp. 275–281.

Bertsch, A., Bernhard, P., Vogt, C. and Renaud, P., 2000, “Rapid Prototyping of Small Size Objects,”Rapid Prototyping Journal, Vol. 6, No.4, pp. 259–266.

Bertsch, A., Jiguet, S. and Renaud, P., 2004, “Microfabrication of Ceramic Components by Microstereolithography,”Journal of Micromechanics and Microengineering, Vol. 14, pp. 197–203.

Choi, J. W., Ha, M. Y., Won, M. H., Choi, K. H. and Lee, S. H., 2005, “Fabrication of 3-Dimensional Microstructures using Dynamic Image Projection,”Proceeding of the 1st International Conference on Precision Engineering and Micro/Nano Technology in Asia, Shenzhen, China, pp. 472–476.

Farsari, M., Claret-Tournier, F., Huang, S., Chatwin, C. R., Budgett, D.M., Birch, P.M., Young, R. C. D. and Richardson, J. D., 2000, “A Novel High-Accuracy Microstereolithography Method Employing an Adaptive Electro-optic Mask,”Journal of Materials Processing Technology 107, pp. 167–172.

Fischer, R. E. and Tadic-Galeb, B., 2000,Optical System Design, McGraw-Hill, pp. 35–47.

Ikuta, K. and Hirowatari, K., 1993, “Real Three Dimensional Micro Fabrication Using Stereolithography and Metal Molding,”Proceedings of the 6th IEEE Workshop on Micro Electro Mechanical Systems (MEMS’93), pp. 42–47.

Ikuta, K., Ogata, T., Tsuboi, M. and Kojima, S., 1996, “Development of Mass Productive Micro Stereo Lithography,”Proceedings of the 8th IEEE Workshop on Micro Electro Mechanical Systems (MEMS’96), Piscataway, NJ, USA, pp. 301–306.

Ikuta, K., Maruo, S. and Kojima, S., 1998, “New Micro Stereo Lithography for Freely Movable 3D Micro Structure — Super IH Process with Submicron Resolution,”Proceedings of the 11th IEEE Workshop on Micro Electro Mechanical Systems (MEMS’98), Heidelberg, Germany, pp. 290–295.

Ikuta, K., Maruo, S., Fujisawa, T. and Yamada, A., 1999, “Micro Concentrator with Opto-Sense Micro Reactor for Biochemical IC Chip Family — 3D Composite Structure and Experimental Verification,”Proceedings of the 12th IEEE Workshop on Micro Electro Mechanical Systems (MEMS ’99), Orlando, Florida, USA, pp. 376–381.

Kim, D. S., Lee, I. H., Kwon, T. H. and Cho, D. W., 2005, “Development of a Three-Dimensional Barrier Embedded Kenics Micromixer by Means of a Micro-Stereolithography Technology,”Journal of KSME A, Vol. 29, No. 6, pp. 904–912.

Lee, I. H., Cho, Y. H., Cho, D.W. and Lee, E. S., 2004, “Development of Micro-Stereolithography System for the Fabrication of Three-Dimensional Micro-Structures,”Journal of KSPE, Vol. 21, No. 3, pp. 171–179.

Lee, I. H. and Cho, D. W., 2004, “An Investigation on Photopolymer Solidification Considering Laser Irradiation Energy in Micro-Stereolithography,”Microsystem Technologies, Vol. 10, No. 8, pp. 592–598.

Limaye, A. S., 2004,Design and Analysis of a Mask Projection Micro-Stereolithography System, M.S. Thesis, Georgia Institute of Technology.

Maruo, S., Ikuta, K. and Korogi, 2003, “Force-Controllable, Optically Driven Micromachines Fabricated by Single-Step Two-Photon Microstereolithography,”Journal of Microelectromechanical Systems, Vol. 12, No. 5, pp. 533–539.

Oda, G., Miyoshi, T., Takaya, Y., Ha, T. H. and Kimura, K., 2004, “Microfabrication of Overhanging Shape using LCD Microstereolithography,”5th International Symposium on Laser Precision Microfabrication, Proceedings of SPIE, Vol. 5662, Bellingham, WA, pp. 649–654.

Park, S. H., Lim, T. W. and Yang, D. W., 2005, “Fabrication of Three-Dimensional Micro-Shell Structures Using Two-Photon Polymerization,”Journal of KSME A, Vol. 29, No. 7, pp. 998–1004.

Park, S. H., Lim, T. W. and Yang, D. Y., 2006, “Investigation into Direct Fabrication of Nano-Patterns Using Nano-Stereolithography (NSL) Process,”Journal of KSPE, Vol. 23, No. 3, pp. 156–162.

Provin, C. and Monneret, S., 2002, “Complex Ceramic-Polymer Composite Microparts Made by Microstereolithography,”IEEE Transactions on Electronics Packaging Manufacturing, Vol. 25, No. 1, pp. 59–63.

Smith, L. B., 2004,Micro-Cross-Sectional Lithography (μCSL™): Prototyping and Packaging for MEMS, Ph. D. Thesis, Rensselaer Polytechnic Institute.

Sun, C. and Zhang, X., 2002, “Experimental and Numerical Investigations on Microstereolithography of Ceramics,”Journal of Applied Physics, Vol. 92, No. 8, pp. 4796–4802.

Sun, C., Fang, N., Wu, D. M. and Zhang, X., 2005, “Projection Micro-Stereolithography Using Digital Micro-Mirror Dynamic Mask,”Sensors and Actuators A: Physical, Vol. 121, Issue 1, 31, pp. 113–120.

Varadan, V. K., Jiang, X. and Varadan, V. V., 2001,Microstereolithography and other Fabrication Techniques for 3D MEMS, Wiley.

Zhang, X., Jiang, X. N. and Sun, C., 1999, “Micro-Stereolithography of Polymeric and Ceramic Microstructures,”Sensors and Actuators 77, pp. 149–156.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, J.W., Ha, Y.M., Lee, S.H. et al. Design of microstereolithography system based on dynamic image projection for fabrication of three-dimensional microstructures. J Mech Sci Technol 20, 2094–2104 (2006). https://doi.org/10.1007/BF02916326

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02916326