Abstract

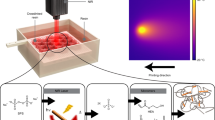

This paper presents a material-efficient multimaterial projection micro-stereolithography (PμSL), a digital light processing (DLP) additive manufacturing process for printing microstructures. We present a droplet-based resin supply system to address the issue of excessive material waste of the multimaterial PμSL. By depositing droplets of different liquid resins, 3D printing of a microstructure can still be performed without the need for a traditional vat while printing materials can be switched with minimal material consumption. Precise control of small droplet volume is obtained by pressure control of the resin injection nozzles, exact opening times of fluid valves, and appropriate surface coatings in order to portion droplets so that just enough material is brought to the build area. Since PμSL enables micro 3D printing (in-plane resolution of 76 μm), PμSL using droplet-based resin supply module provides multimaterial micro 3D printing with low material consumption. Also reported is that material bleeding, which degrades the printing resolution during multimaterial printing, can be minimized by using a cleaning droplet system. We present 3D printing of highly complex multimaterial 3D microstructures using three different photocurable polymers, demonstrating a material efficiency of 11.4%, which is 500 times higher than that of a previously reported PμSL process using dynamic fluidic control.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request.

References

Gibson, I., Rosen, D. W., Stucker, B., Khorasani, M., Rosen, D., Stucker, B., & Khorasani, M. (2021). Additive manufacturing technologies. Springer. https://doi.org/10.1007/978-3-030-56127-7

Kim, S., Kim, D. H., Kim, W., Cho, Y. T., & Fang, N. X. (2021). Additive manufacturing of functional microarchitected reactors for energy, environmental, and biological applications. International Journal of Precision Engineering and Manufacturing-Green Technology, 8, 303–326. https://doi.org/10.1007/s40684-020-00277-5

Auyeskhan, U., Kim, N., Kim, C. S., Van Loi, T., Choi, J., & Kim, D. H. (2021). Design approach for additive manufacturing of a dynamically functioning system: Lifeboat hook. International Journal of Precision Engineering and Manufacturing-Green Technology, 9, 1349–1367. https://doi.org/10.1007/s40684-021-00399-4

Han, D., & Lee, H. (2020). Recent advances in multi-material additive manufacturing: Methods and applications. Current Opinion in Chemical Engineering, 28, 158–166. https://doi.org/10.1016/j.coche.2020.03.004

Lalegani Dezaki, M., & Bodaghi, M. (2023). A review of recent manufacturing technologies for sustainable soft actuators. International Journal of Precision Engineering and Manufacturing-Green Technology, 10, 1661–1710. https://doi.org/10.1007/s40684-023-00533-4

Overvelde, J. T. (2019). How to print multi-material devices in one go. Nature, 575, 289–290. https://doi.org/10.1038/d41586-019-03408-4

Skylar-Scott, M. A., Mueller, J., Visser, C. W., & Lewis, J. A. (2019). Voxelated soft matter via multimaterial multinozzle 3D printing. Nature, 575, 330–335. https://doi.org/10.1038/s41586-019-1736-8

Hao, L., Tang, D., Sun, T., Xiong, W., Feng, Z., Evans, K. E., & Li, Y. (2021). Direct ink writing of mineral materials: A review. International Journal of Precision Engineering and Manufacturing-Green Technology, 8, 665–685. https://doi.org/10.1007/s40684-020-00222-6

Fekiri, C., Kim, C., Kim, H. C., Cho, J. H., & Lee, I. H. (2022). Multi-material additive fabrication of a carbon nanotube-based flexible tactile sensor. International Journal of Precision Engineering and Manufacturing, 23, 453–458. https://doi.org/10.1007/s12541-022-00632-3

Rafiee, M., Farahani, R. D., & Therriault, D. (2020). Multi-material 3D and 4D printing: A survey. Advanced Science, 7, 1902307. https://doi.org/10.1002/advs.201902307

Patpatiya, P., Chaudhary, K., Shastri, A., & Sharma, S. (2022). A review on polyjet 3D printing of polymers and multi-material structures. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 236, 7899–7926. https://doi.org/10.1177/09544062221079506

Gwon, M., Park, G., Hong, D., Park, Y. J., Han, S., Kang, D., & Koh, J. S. (2022). Soft directional adhesion gripper fabricated by 3D printing process for gripping flexible printed circuit boards. International Journal of Precision Engineering and Manufacturing-Green Technology, 9, 1151–1163. https://doi.org/10.1007/s40684-021-00368-x

Sun, C., Fang, N., Wu, D., & Zhang, X. (2005). Projection micro-stereolithography using digital micro-mirror dynamic mask. Sensors and Actuators A: Physical, 121, 113–120. https://doi.org/10.1016/j.sna.2004.12.011

Ge, Q., Li, Z., Wang, Z., Kowsari, K., Zhang, W., He, X., Zhou, J., & Fang, N. X. (2020). Projection micro stereolithography based 3D printing and its applications. International Journal of Extreme Manufacturing, 2, 022004. https://doi.org/10.1088/2631-7990/ab8d9a

Han, D., Lu, Z., Chester, S. A., & Lee, H. (2018). Micro 3D printing of a temperature-responsive hydrogel using projection micro-stereolithography. Scientific Reports, 8, 1963. https://doi.org/10.1038/s41598-018-20385-2

Choi, J.-W., Kim, H.-C., & Wicker, R. (2011). Multi-material stereolithography. Journal of Materials Processing Technology, 211, 318–328. https://doi.org/10.1016/j.jmatprotec.2010.10.003

Zhou, C., Chen, Y., Yang, Z., & Khoshnevis, B. (2013). Digital material fabrication using mask-image-projection-based stereolithography. Rapid Prototyping Journal, 19, 153–165. https://doi.org/10.1108/13552541311312148

Mu, Q., Wang, L., Dunn, C. K., Kuang, X., Duan, F., Zhang, Z., Qi, H. J., & Wang, T. (2017). Digital light processing 3D printing of conductive complex structures. Additive Manufacturing, 18, 74–83. https://doi.org/10.1016/j.addma.2017.08.011

Han, D., Yang, C., Fang, N. X., & Lee, H. (2019). Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Additive Manufacturing, 27, 606–615. https://doi.org/10.1016/j.addma.2019.03.031

Bong, K. W., Chapin, S. C., Pregibon, D. C., Baah, D., Floyd-Smith, T. M., & Doyle, P. S. (2011). Compressed-air flow control system. Lab on a Chip, 11, 743–747. https://doi.org/10.1039/C0LC00303D

White, F. M. (2015). Fluid mechanics (8th ed.). McGraw Hill.

Wang, Q., Jackson, J. A., Ge, Q., Hopkins, J. B., Spadaccini, C. M., & Fang, N. X. (2016). Lightweight mechanical metamaterials with tunable negative thermal expansion. Physical Review Letters, 117, 175901. https://doi.org/10.1103/PhysRevLett.117.175901

Zheng, X., Deotte, J., Alonso, M. P., Farquar, G. R., Weisgraber, T. H., Gemberling, S., Lee, H., Fang, N., & Spadaccini, C. M. (2012). Design and optimization of a light-emitting diode projection micro-stereolithography three-dimensional manufacturing system. Review of Scientific Instruments, 83, 125001. https://doi.org/10.1063/1.4769050

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 1711154190, RS-2023-00218543, RS-2023-00221987, RS-2022-00166341). This work was also supported by SNU Creative-Pioneering Researchers Program. The authors also gratefully acknowledge the support from Rutgers University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tobia, J., Yang, C., Kim, J. et al. Material-Efficient Multimaterial Projection Micro-stereolithography Using Droplet-Based Resin Supply. Int. J. of Precis. Eng. and Manuf.-Green Tech. (2024). https://doi.org/10.1007/s40684-023-00585-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40684-023-00585-6