Abstract

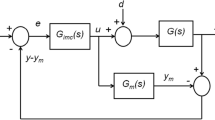

This chapter compares the design, implementation and performance of direct and indirect adaptive control (AC) to improve part quality in the stamping process in the presence of disturbances. First, previous work on the design and performance of a direct AC approach (i.e., model reference adaptive control or MRAC) is summarized. The direct AC filter uses nominal process parameters, and so requires some knowledge of the process. Consequently, an indirect AC approach, which estimates process parameters on-line, was also considered. However, due to the simple proportional plus integral (PI) control structure selected, the computation of the controller gains from the estimated parameters requires an optimization procedure, which is not amenable to real-time implementation. Thus, the indirect AC is implemented using a look-up table, with controller gains that are pre-computed off-line via optimization. The indirect AC with the look-up table is compared to the direct AC via simulations and experiments in terms of tracking performance as well as part quality, in the presence of plant variations. The indirect AC, with a sufficiently high level of discretization in the look-up table, performs well in simulations. However, due to extensive memory requirements, a smaller look-up table is used in the experiments, where it is outperformed by the direct AC.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Astrom, K. J., Wittenmark, B., 1995, Adaptive Control, Prentice Hall, 2nd edition.

Boling, J.M., Seborg, D.E., Hespanha, J.P., 2007, “Multi-model adaptive control of a simulated pH neutralization process,” Control Engineering Practice, Vol. 15, Issue 6, Special Section on Control Applications in Marine Systems—CAMS2004, Control Applications in Marine Systems, June 2007, pp. 663–672.

Chia, T.L., Chow, P.-C., Chizeck, H.J., 1991, “Recursive Parameter Identification of Constrained Systems: An Application to Electrically Stimulated Muscle,” IEEE Trans. Biomed. Eng., Vol. 38, pp. 429–442.

Devasia, S., 2002, “Should Model-Based Inverse Inputs Be Used as Feedforward Under Plant Uncertainty?,” IEEE Trans. on Automatic Control, Vol. 47, no. 11, pp. 1865–1871.

Goodwin, G.C., Sin, K.W., 1984, Adaptive Filtering, Prediction, and Control, Prentice-Hall: Englewood Cliffs, NJ.

Hsu, C.W., Ulsoy, A.G., Demeri, M.Y., 2000, “An Approach for Modeling Sheet Metal Forming for Process Controller Design,” ASME J. Manuf. Sci. Eng., Vol. 122, pp. 717–724.

Hsu, C. W., Ulsoy, A. G., Demeri, M. Y., 2002, “Development of process control in sheet metal forming,” J. of Materials Proc. Tech., Vol. 127, pp. 361–368.

Ioannou, P.A., Kokotovic, P.V., 1984, “Instability Analysis and Improvement of Robustness of Adaptive Control,” Automatica, Vol. 20, no. 5, pp. 583–594.

Ioannou, P.A., Sun, J., 1996, Robust Adaptive Control, New Jersey: Prentice-Hall.

Karimi, A., Butcher, M., Longchamp, R., 2008, “Model-Free Pre-compensator Tuning Based on the Correlation Approach,” IEEE Trans. on Control Systems Tech., Vol. 16, pp. 1013–1020.

Kreisselmeier, G., 1985, “An Approach to Stable Indirect Adaptive Control,” Automatica, Vol. 21, no. 4, pp. 425–431.

Lagarias, J.C., Reeds, J.A., Wright, M.H., Wright, P.E., 1998, “Convergence Properties of the Nelder-Mead Simplex Method in Low Dimensions,” SIAM Journal of Optimization, Vol. 9, no. 1, pp. 112–147.

Lauderbaugh, L.K., Ulsoy, A.G., 1989, “Model Reference Adaptive Force Control in Milling,” ASME J. of Engineering for Industry, Vol. 111, no. 1, pp. 13–21.

Lim, Y.S., 2010, MIMO Adaptive Process Control in Stamping Using Punch Force, Ph.D. Dissertation, University of Michigan, Ann Arbor, Michigan.

Lim, Y.S., Venugopal, R., Ulsoy, A.G., 2009, “Improved Part Quality in Stamping Using Multi-Input Multi-Output Process Control,” Proceedings of American Control Conference, Saint Louis, MO, USA, June 10-12, 2009, pp. 5570–5575.

Lim, Y.S., Venugopal, R., Ulsoy, A.G., 2010, “Multi-Input Multi-Output Modeling and Control for Stamping,” ASME J. of Dyn. Systems, Meas., and Control, Vol. 132, Issue 4, 041004.

Lim, Y.S., Venugopal, R., Ulsoy, A.G., 2012, “Auto-Tuning and Adaptive Stamping Process Control,” Control Engineering Practice, Vol. 20, pp. 156–164.

Quintana-Ortí, G., Quintana-Ortí, E. S., Petitet, A., 1998, “Efficient Solution of The Rank-Deficient Linear Squares Problem,” SIAM J. Sci. Comput., Vol. 20, no. 3, pp. 1155–1163.

Sunseri, M., Cao, J., Karafillis, A.P., Boyce, M.C., 1996, “Accommodation of Springback Error in Channel Forming Using Active Binder Force: Control Numerical Simulations and Experiments,” J. of Engin. Materials and Tech., Vol. 118, pp. 426–435.

Rupp, D. and Guzzella, L., 2010, “Adaptive internal model control with application to fueling control,” Control Engineering Practice, Vol. 18, Issue 8, pp. 873–881.

Tomizuka, M., 1987, “Zero Phase Error Tracking Algorithm for Digital Control,” ASME J. of Dynamic Systems, Measurement, and Control, Vol. 109, pp. 65–68.

Tsai, Ching-Chih, Lin, Shui-Chun, Wang, Tai-Yu, Teng, Fei-Jen, 2009, “Stochastic model reference predictive temperature control with integral action for an industrial oil-cooling process,” Control Engineering Practice, Vol. 17, Issue 2, pp. 302–310.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Copyright information

© 2014 Springer-Verlag London

About this chapter

Cite this chapter

Lim, Y., Venugopal, R., Ulsoy, A.G. (2014). Direct and Indirect Adaptive Process Control. In: Process Control for Sheet-Metal Stamping. Advances in Industrial Control. Springer, London. https://doi.org/10.1007/978-1-4471-6284-1_8

Download citation

DOI: https://doi.org/10.1007/978-1-4471-6284-1_8

Published:

Publisher Name: Springer, London

Print ISBN: 978-1-4471-6283-4

Online ISBN: 978-1-4471-6284-1

eBook Packages: EngineeringEngineering (R0)